Bevel guiding-groove honeycomb-hole manhole cover

A honeycomb hole and manhole cover technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of opening, difficulty and difficulty of manhole covers that cannot be drained into the well, so as to reduce casualties and property losses, reduce phenomena, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

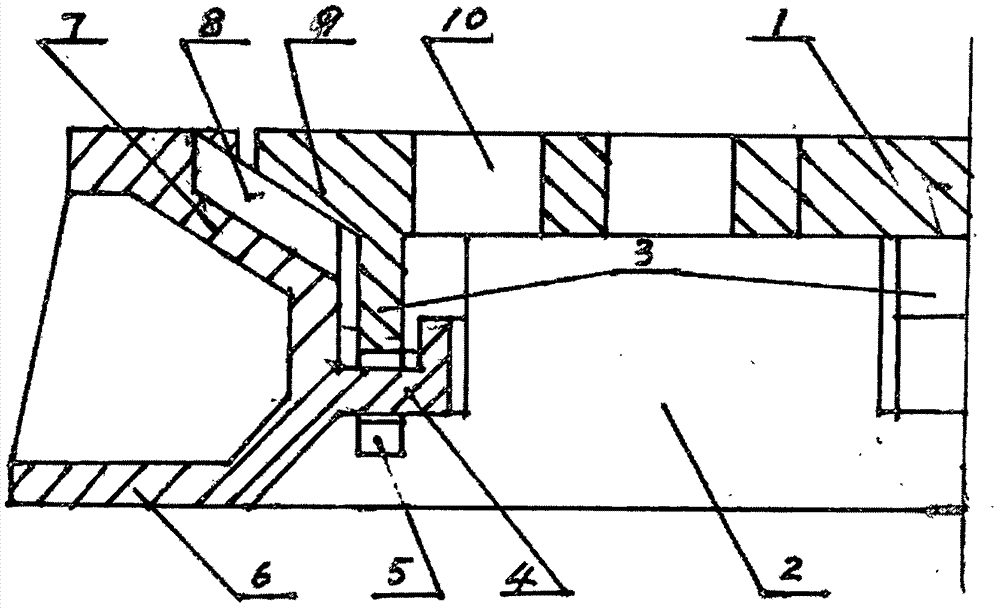

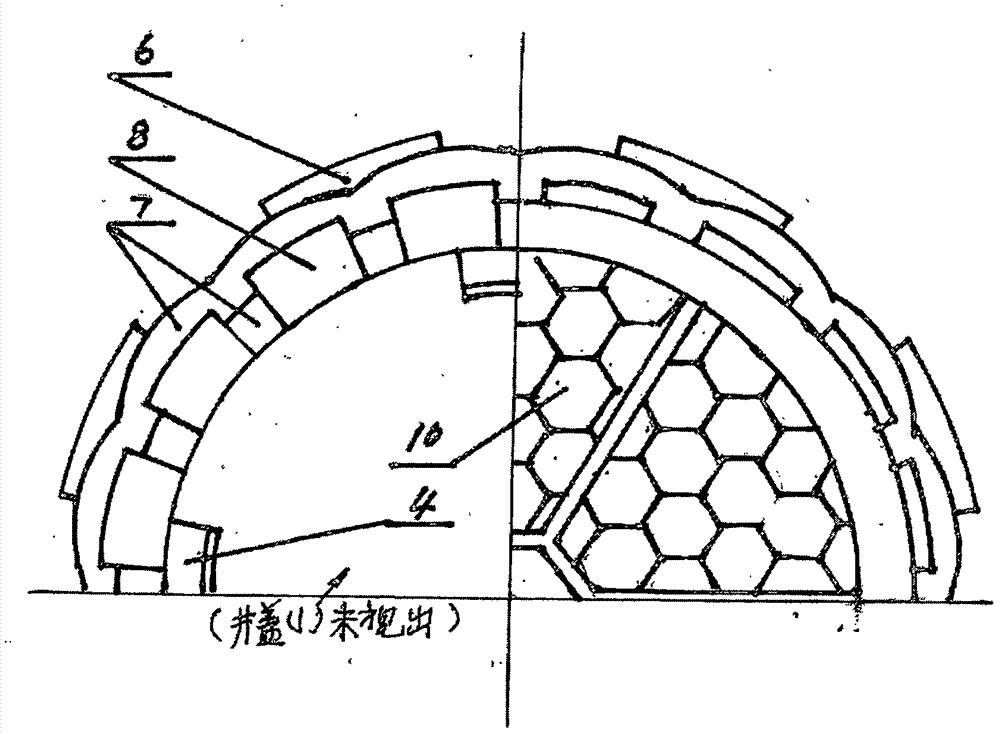

[0020] The present invention can be used for drainage and rainwater collection manhole covers of any material and shape. Now take the circular inspection manhole cover of nodular cast iron as an example for specific description. First, determine the size and grade of the manhole cover according to the conditions and locations of use, and select heavy-duty manhole covers for main roads. . Light well covers are used in back streets and alleys. The section of the diversion channel can be smaller when used in high-lying places, and the section of the diversion channel should be larger when used in low-lying places. The shape of the manhole cover can be petal-shaped. After the above basic elements are determined, the production drawings can be drawn, and then the wood type can be made according to the drawings. If it is mass production, the metal mold needs to be copied, and finally the ductile iron manhole cover and well seat products are remade according to the mold. The explanat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com