Tin brushing device for wire terminal

A technology of wire joints and equipment, applied in the direction of circuits, connections, electrical components, etc., can solve the problems of heating oxidation, poor tin quality, cumbersome steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

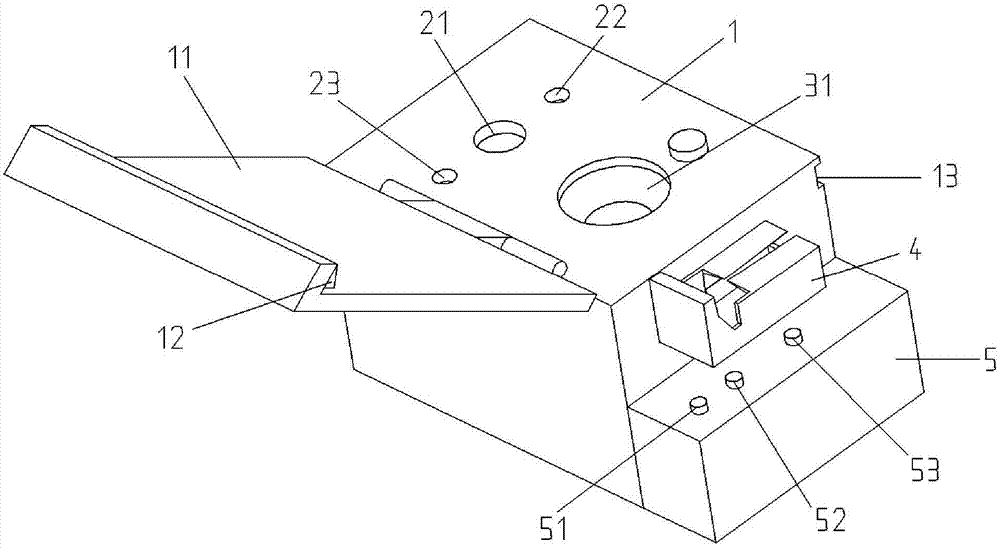

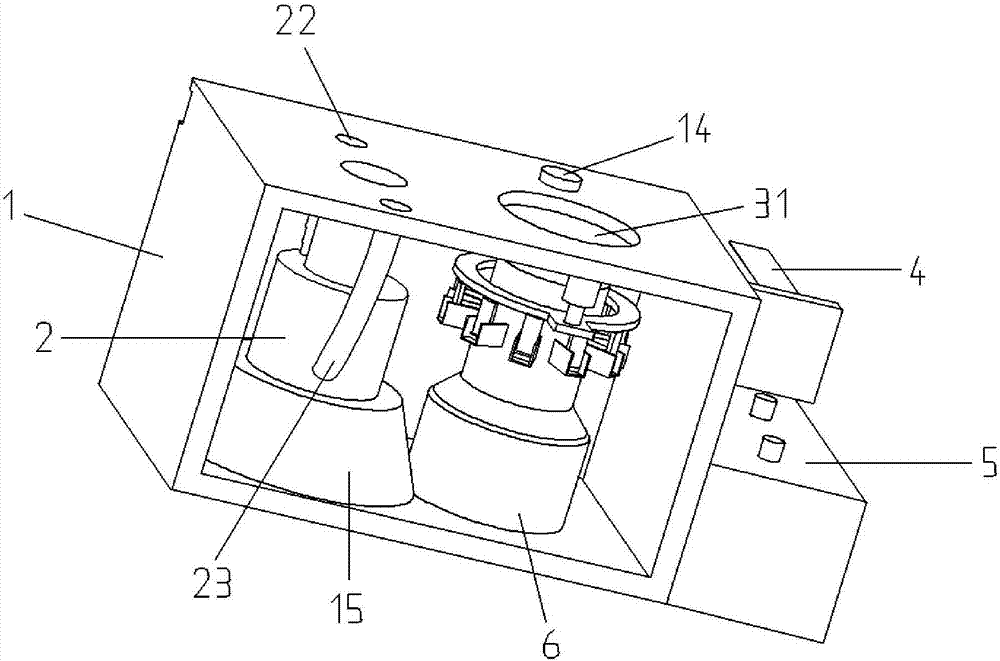

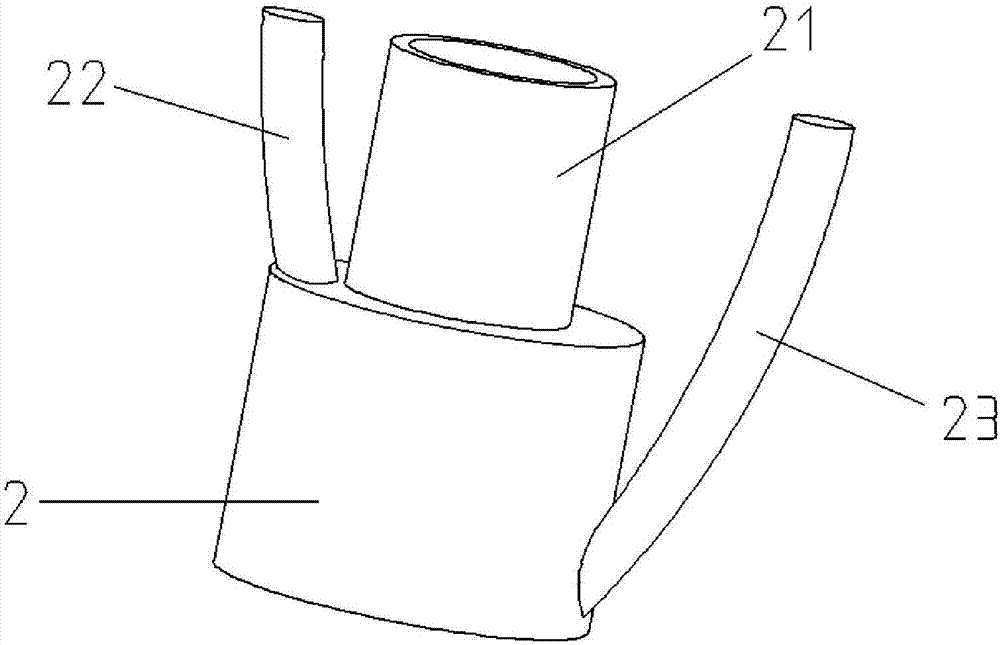

[0025] Such as Figure 1 to Figure 10 As shown, a kind of tinning equipment for electric wire joints includes a tinning shell 1, a shaft-mounted end cover 11, a rubber card body 12, a card slot 13, a tin block inlet 14, a support body 15, a solution tank 2, a liquid coating port 21, Alcohol feed port 22, rosin feed port 23, rinsing tin body 3, tin coating port 31, positioning body 32, slide rail groove 321, tin liquid tank 33, electric heating plate 34, peeling body 4, peeling knife seam 41 , line leather groove 42, baffle plate 43, power supply 5, ascending switch 51, descending switch 52, electric heating switch 53, heat shield 6, cylinder 7, lifting body 71, rotary gear 8, lifting slide plate 81, limit body 82, Slide bar 821, rack 822, scraping body 9, shrapnel 91, described rinse tin shell 1 interior is provided with cavity, is provided with a solution tank 2 and a tin rinse body 3 side by side in the cavity, described solution Groove 2 and rinse tin body 3 tops are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com