A control method for fluorescent transparent ceramic high-power LED light source

A technology of LED light source and transparent ceramics, applied in the field of LED light source, can solve the problems of shortening the service life of light source, damage of light source, uneven heating of ceramics, etc., achieve good market application prospects and improve the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described.

[0023] Structural composition and application example description of the embodiment of the present invention:

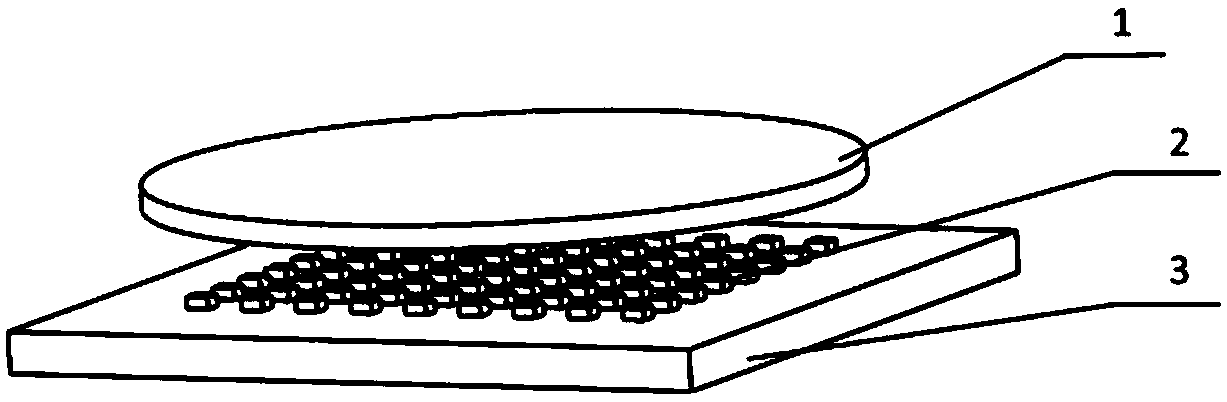

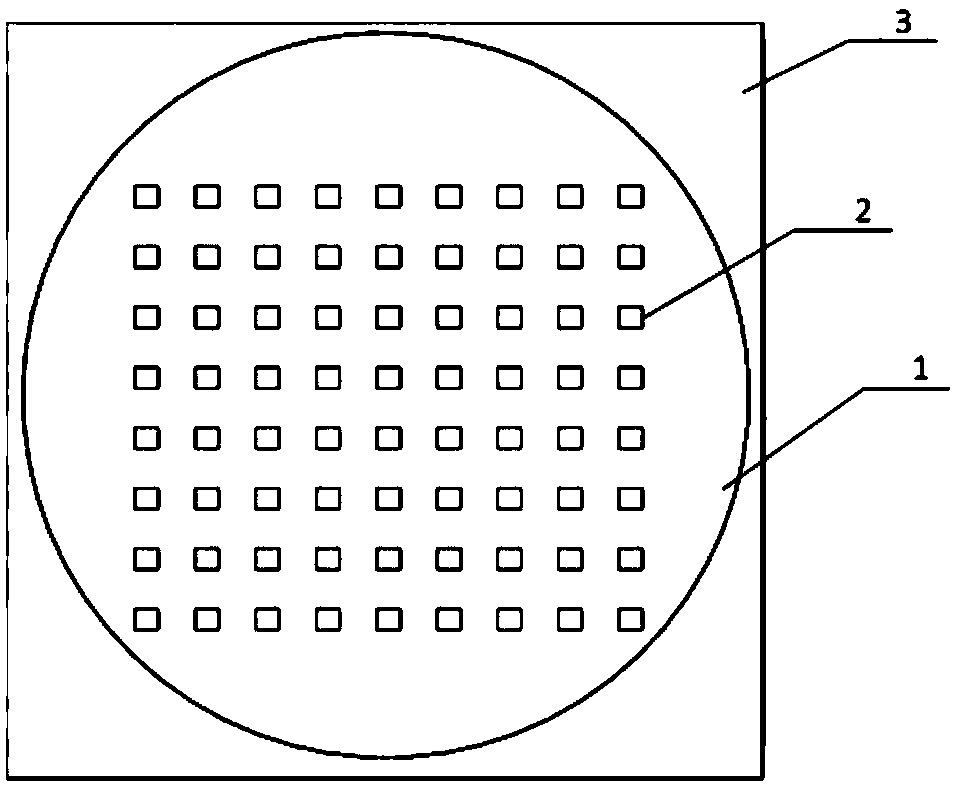

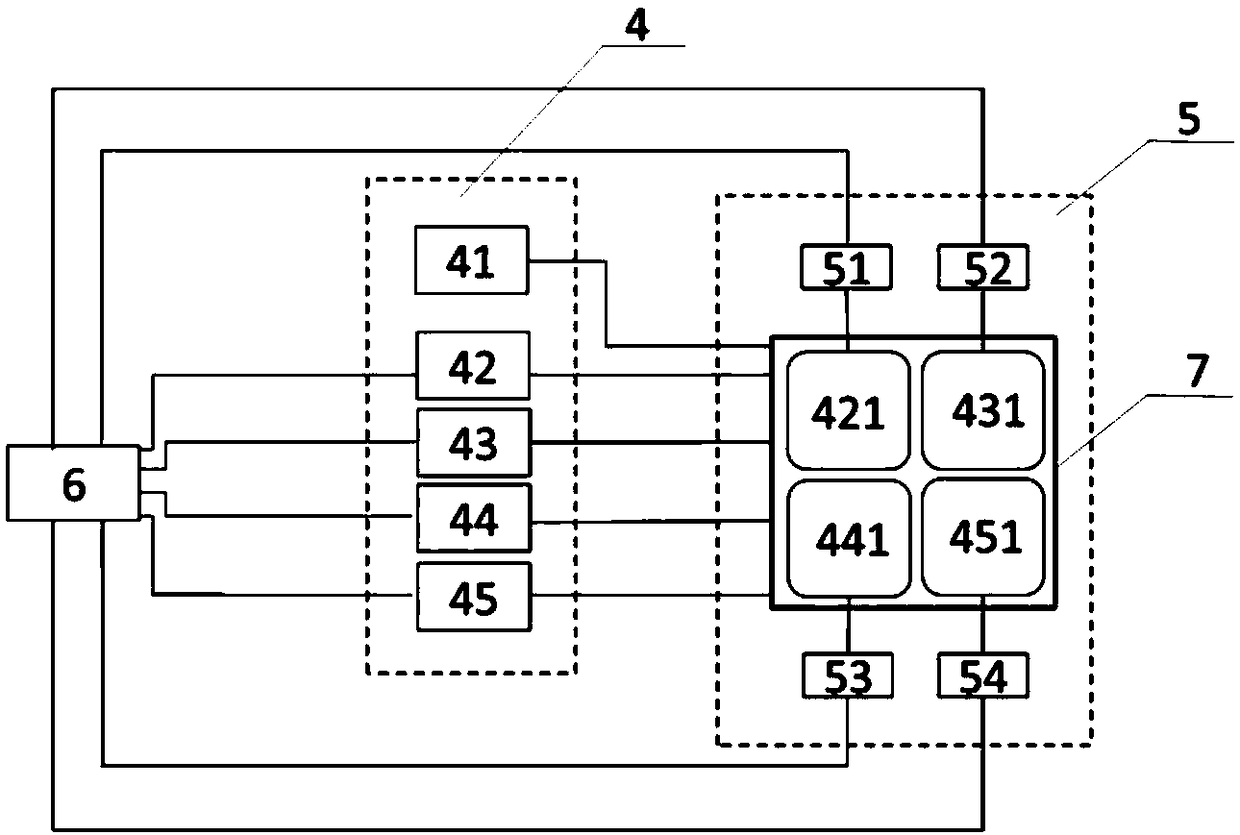

[0024] The component structure of the light source is as follows figure 1 and 2 As shown, mark 1 represents high-quality fluorescent transparent ceramics; mark 2 represents LED chip; mark 3 represents aluminum substrate. In the embodiment, the LED array is divided into four areas, and a red LED chip ( Figure 4 The hollow core chip is represented as a red light LED chip), and the partition method and the number of red light chips can be adjusted according to specific conditions. image 3 It is a block diagram of the structure of the embodiment of the present invention. In this embodiment, a current source module 4 and a light source module 5 are provided. Current source module 4 comprises: mark 41, is used for providing stable current for the red light LED c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com