Selective catalytic reduction denitration device and ammonia spray optimizing method thereof

An optimization method and selective technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as poor optimization effect, high adjustment blindness, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

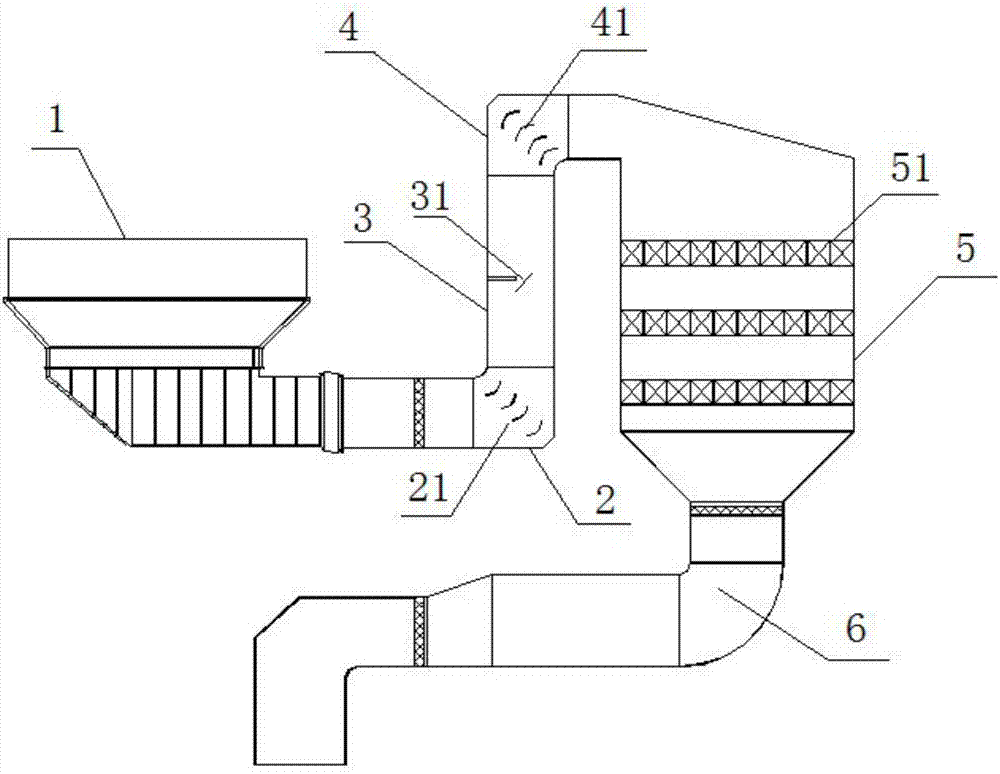

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

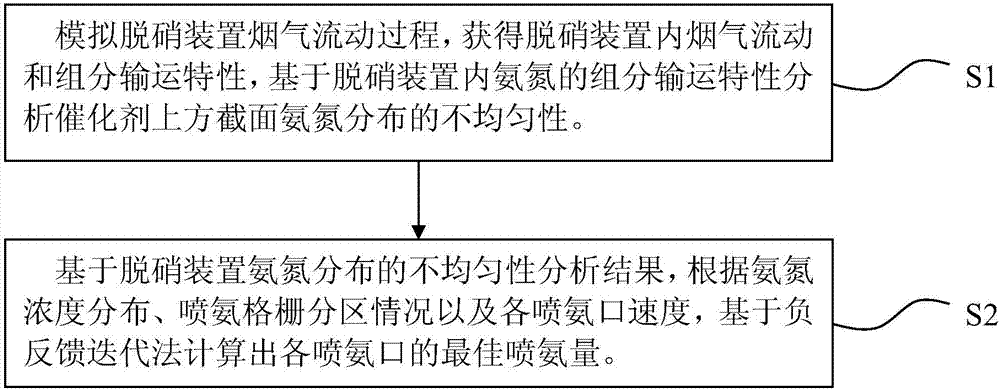

[0031] ginseng figure 1 As shown, this embodiment provides an ammonia injection optimization method for a selective catalytic reduction denitrification device, including:

[0032] Step S1, simulating the flue gas flow process of the denitrification device, obtaining the flue gas flow and component transport characteristics in the denitrification device, and analyzing the inhomogeneity of the distribution of ammonia nitrogen in the section above the catalyst based on the component transport characteristics of ammonia nitrogen in the denitrification device;

[0033] Step S2, based on the non-uniformity analysis results of the ammonia nitrogen distribution of the denitrifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com