Roller press capable of applying electric field

A technology of applying voltage and rolling machine, which is applied in the field of rolling machine, can solve the problems of difficult transmission of friction and shear force, poor crushing or dispersion effect, weak interaction, etc., to achieve enhanced shearing effect, improved grinding efficiency, enhanced interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

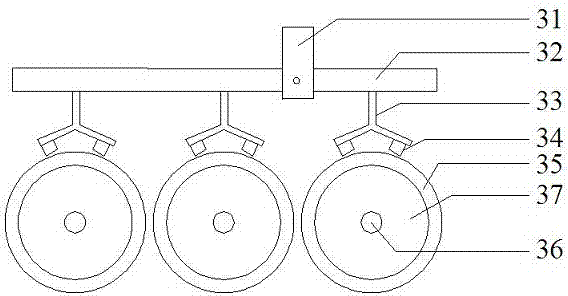

[0035] There are at least two pressing rollers, and charges of different polarities are applied between adjacent pressing rollers.

[0036] According to the different number of pressing rollers, there are many ways to apply electric field. For example, when there are more than 2 pressing rollers, charges of opposite polarity can be applied on adjacent pressing rollers. If there are 4 pressing rollers, the first and third The pressure rollers are positively charged and the 2 and 4 pressure rollers are negatively charged.

Embodiment 2

[0038] The number of the pressure rollers is at least n+1, wherein n is an even number except 0, no charge is applied to the nth pressure roller, and different poles are respectively applied to the two pressure rollers adjacent to the nth pressure roller. sexual charge.

[0039]When the number of pressure rollers is 3, 5, 7, 9..., the way of applying the electric field can be +, 0, -, 0, +, 0, -, 0 means no electric field is applied, that is, the first, third, and fifth Positive charges are applied to odd-numbered rollers, and negative charges are applied to even-numbered rollers such as 2 and 4.

[0040] Of course, the way of applying the electric field can also be the same as in Embodiment 1, and electric fields of different polarities are set between two adjacent pressing rollers.

Embodiment 3

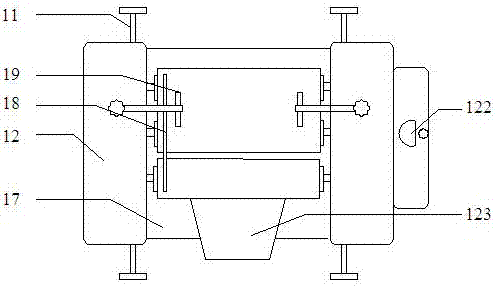

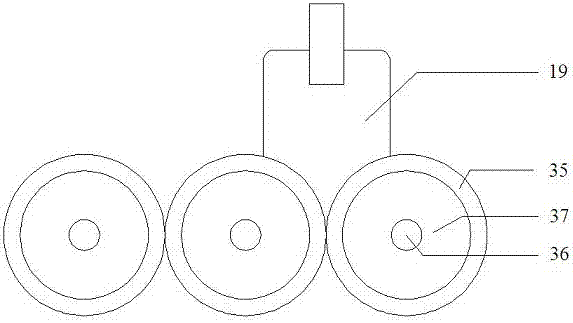

[0042] Taking the three-roll machine as an example, the adjacent press rolls are electrically insulated, and the roll surfaces of the press rolls are made of conductive materials. In order to realize electrical insulation between adjacent pressing rollers, the pressing rollers are fixed on the frame through bearings, and the bearings are made of insulating materials.

[0043] The electric field application method can be +, -, +, that is, positive charges are applied to the first and third pressing rollers, and negative charges are applied to the second pressing roller.

[0044] The electric field application method of the three-roll machine can also be: +, 0, -, that is, no electric field is applied to the second pressure roller, and only an electric field with opposite polarity is applied to the first and third pressure rollers, so that the pressure on the pressure roller have different charges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com