Rotary shaft drilling machining fixing seat in workshop

A fixed seat and shaft technology, used in large fixed members, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult to control the size of the force, uneven clamping force, time-consuming and laborious, and achieve easy and fast clamping. The effect of holding and fixing, improving product quality, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

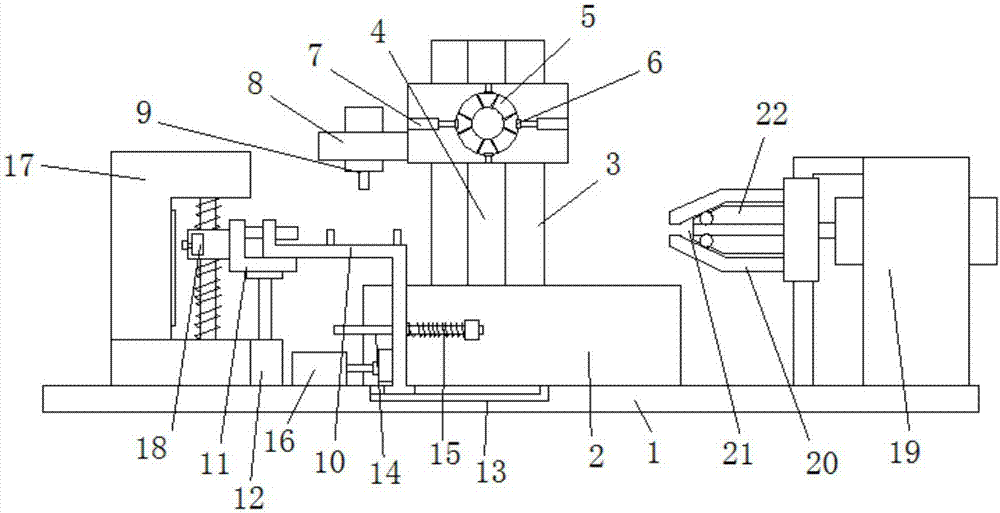

[0010] Referring to the accompanying drawings, a fixing seat for drilling and processing of rotating shafts in a workshop includes a base 1 on which a cleaning pool 2 is fixedly installed. The side wall of 3 is provided with a chute 4, and a cylindrical jacket 5 is slidably installed in the chute 4, and a plurality of annularly distributed clamping blocks 6 are arranged on the side wall of the jacket 5. Each clamping block 6 is regulated by adjusting rod 7 to carry out clamping operation respectively, and the center of described jacket 5 is provided with workpiece hole, and the side wall of described cylindrical jacket 5 is provided with support plate 8, and described support A drill bit 9 is fixedly installed on the side wall of the plate 8, a support platform 10 is provided below the drill bit 9, and the left end of the support platform 10 is lapped on the sliding support seat 11, and the bottom of the sliding support seat 11 is provided with Jacking cylinder 12, the jacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com