Wood processing device for wood packaging box

A processing device and packaging box technology, which is applied to machine tools, metal processing equipment, grinding/polishing safety devices, etc., which are suitable for grinding the edge of workpieces. Sawdust and other problems to achieve the effect of improving collection capacity, improving grinding efficiency, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

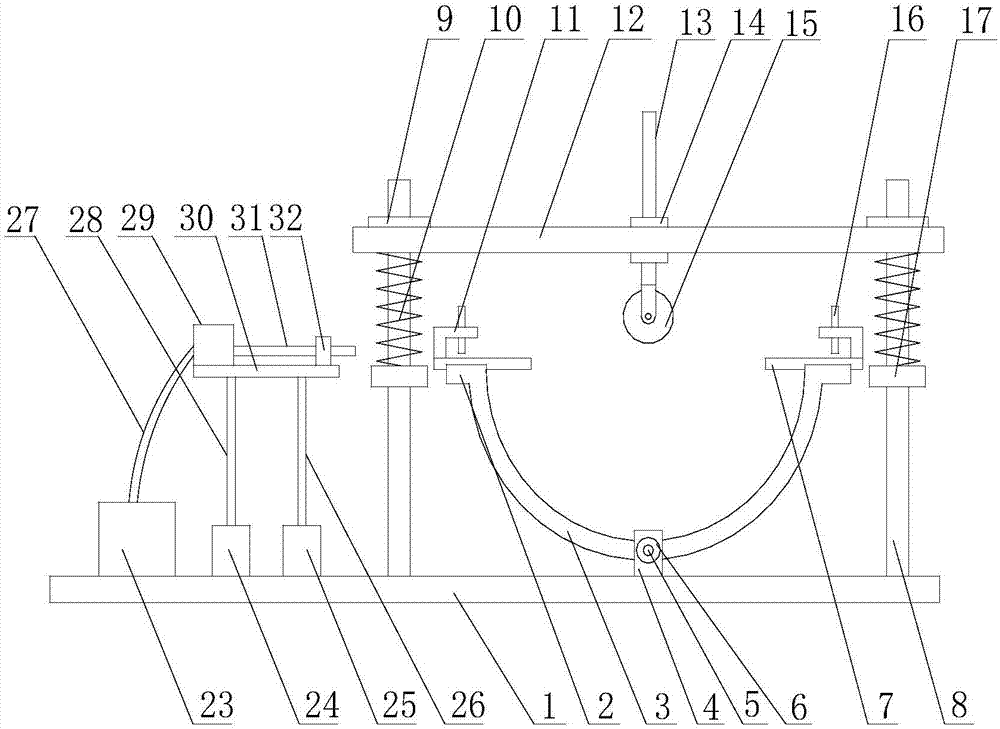

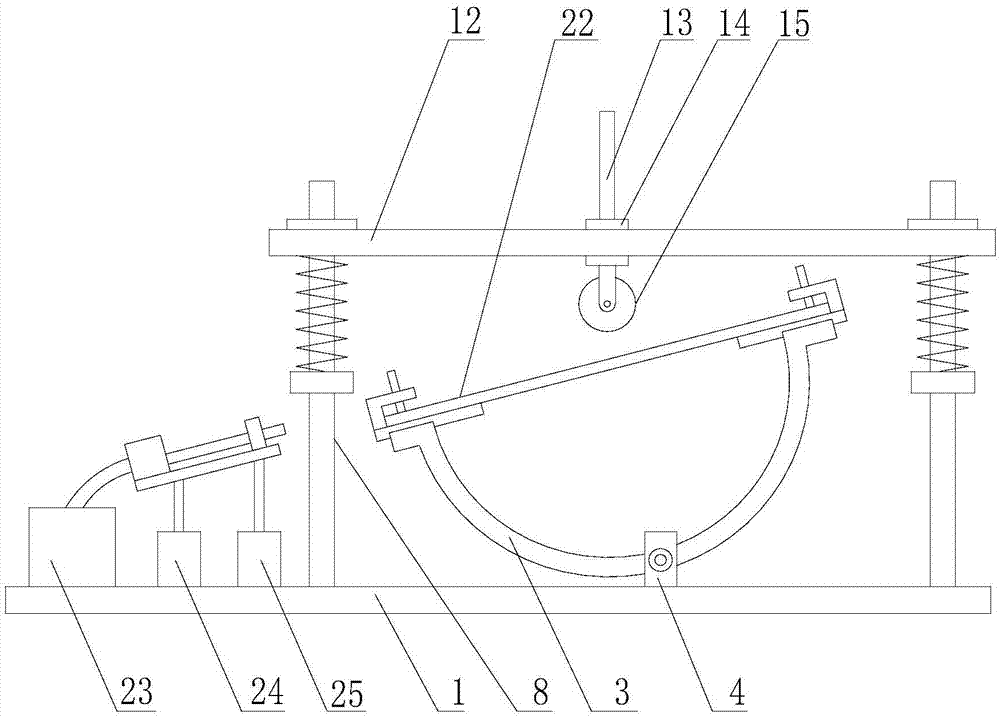

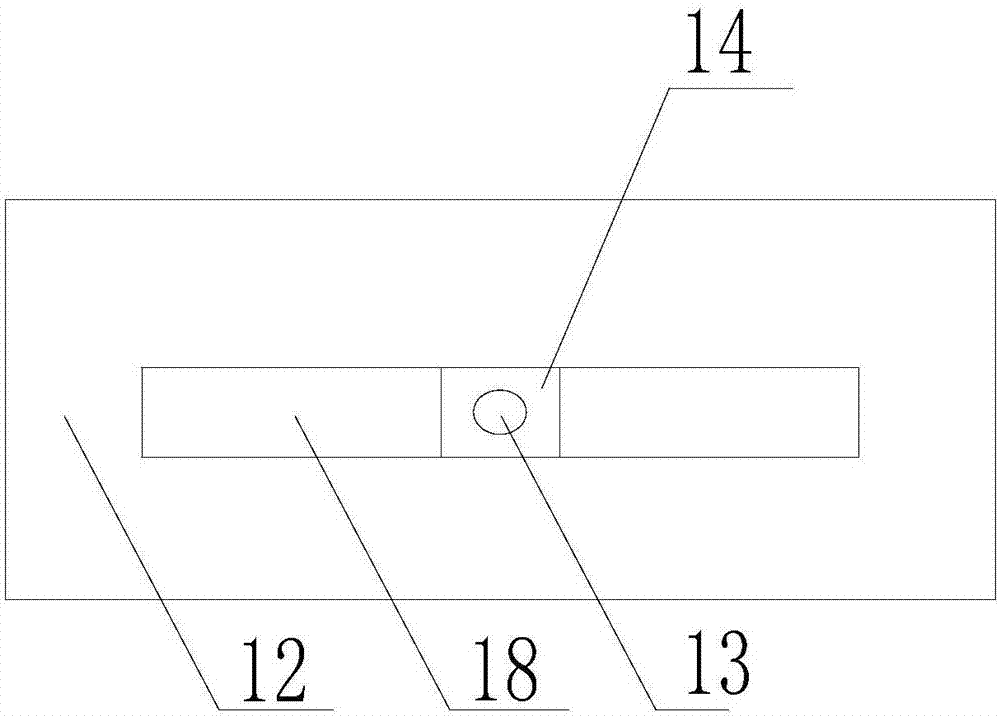

[0028] Such as Figure 1 to Figure 5As shown, the wood processing device used for wooden packaging boxes of the present invention includes a machine base 1, the top of the machine base 1 is provided with a fixed block 4, the fixed block 4 is located at the central position of the machine base 1, and the top of the fixed block 4 A groove 21 is provided, and an arc-shaped support frame 3 with an opening facing upward is arranged in the groove 21, and a rotating rod 5 is also provided on the fixed block 4, and the rotating rod 5 is inserted through the rotating rod 5 in the groove 21, Turning bar 5 can rotate in fixed block 4, and when turning bar 5 rotates, bracing frame 3 will follow and rotate together, and turning bar 5 is also provided with fastening block 6, and fastening block 6 is connected with turning bar 5 by screw thread, The fastening block 6 is a nut. When the fastening block 6 is unscrewed, the rotating rod 5 can rotate in the fixed block 6. When the fastening bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com