Transport vehicle for small prefabricated blocks

A technology of prefabricated blocks and transport vehicles, applied in the field of transport vehicles, can solve the problems of low prefabricated block prefabrication efficiency, easy damage of prefabricated block molds, and large investment of transportation personnel, etc., to achieve the effect of improving prefabricated quality, reducing manpower, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Such as Figures 3 to 5 shown

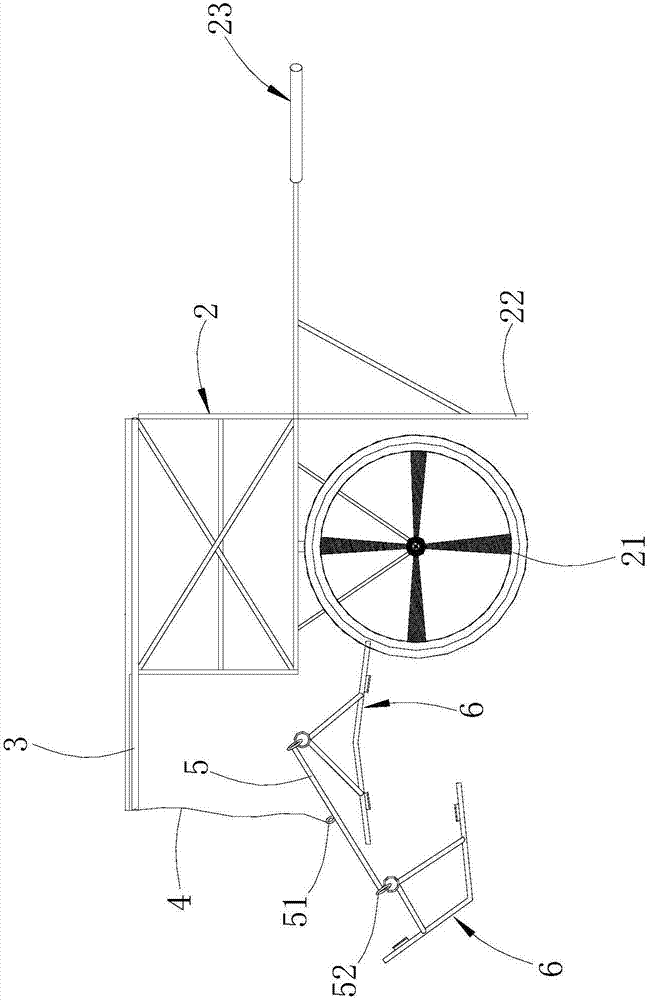

[0018] The small-sized prefabricated block transport vehicle comprises a vehicle frame 2, a lifting steel pipe 3, a lifting wire rope 4 and a conveying assembly.

[0019] The vehicle frame 2 is a frame structure composed of several steel pipes. Two wheels 21 (commonly used trolley wheels) are installed on the lower side of the vehicle frame 2. The two wheels 21 are connected by rotating shafts. The lower part of the vehicle frame 2 is supported on the wheels 21 by multiple steel pipes. On the rotating shaft, the above-mentioned steel pipes are fixed in pairs by using an inverted triangle structure to fix the vehicle frame 2 and the axle. The rear part of the vehicle frame 2 extends downward with outriggers 22 that can be in contact with the ground, and a handle extends backward on the vehicle frame 2. 23, the handle 23 is sleeved with a plastic sleeve.

[0020] The lifting steel pipe 3 is welded on the upper end of the frame 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com