High-performance water-reducing agent and preparation method thereof

A water reducer, high-performance technology, applied in the field of high-performance water reducer and its preparation, can solve the problems of short retardation time, difficult control of esterification rate, low ability of polymer slump, etc., to achieve good water reducer Good water performance, fluidity retention and slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

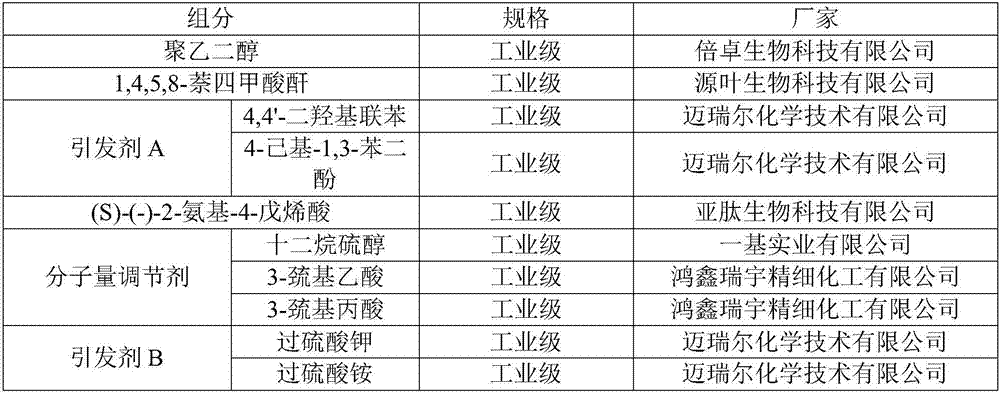

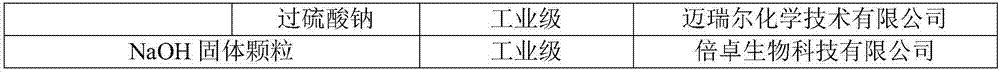

[0041] The preparation method of the high-performance water reducer in each of the above embodiments is as follows:

[0042] Esterification: Take polyethylene glycol and 1,4,5,8-naphthalene tetracarboxylic anhydride, melt the polyethylene glycol and 1,4,5,8-naphthalene tetracarboxylic anhydride and add them to the reaction kettle at the same time, stir evenly , filled with nitrogen, the nitrogen flow rate is S, at the same time add the initiator A, increase the temperature T of the reactor 1 , stir evenly t 1 , then add concentrated sulfuric acid, continue to raise the temperature T of the reactor 2 , stir evenly t 2 , after the reaction is completed, the esterified macromonomer is obtained;

[0043] Polymerization: Take the prepared macromer, (S)-(-)-2-amino-4-pentenoic acid, and molecular weight regulator and mix evenly to obtain mixture C; take initiator B and deionized water and mix evenly, Obtain mixture D; Reactor is warmed up to T 3 , while adding mixture C and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com