Composite type control cable for coal cutter

A control cable and composite technology, which is applied in the direction of electric control power cables, power cables, insulated cables, etc., can solve the problems of affecting the service life of the cables, the cables cannot operate normally, and the control wire core is broken, so as to reduce repeated investment , Improve the anti-interference ability and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further illustrate the inventive concept of the present invention, the specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

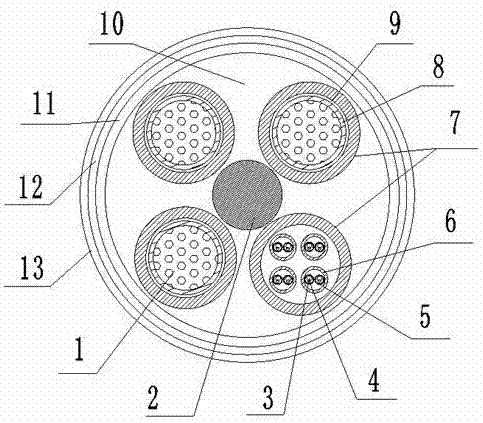

[0013] Such as figure 1 As shown, a composite control cable for a coal mining machine according to the present invention includes a cable core composed of three power cores 1, one ground core 2 and eight signal cores 3, and each of the signal cores The wire cores 3 are wrapped with a signal insulating layer 5, and every two signal wire cores 3 form a group, and each group of signal wire cores 3 is wrapped with a signal shielding layer 6, and the four groups of signal wire cores 3 are arranged in a rectangular shape. And outside the signal shielding layer 6 is wrapped with a tape layer 7, the ground core 2 is located in the center of the cable core, three power cores 1 and eight signal cores 3 are arranged around the ground core 2, In the power core 1, a power insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com