Sound attenuation method of pulse valves of pulse bag filter

A technology of bag filter and pulse valve, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of noise pollution, unspecified treatment methods, and unspecified treatment equipment, etc., to achieve noise reduction Difficult, noise-reducing and sound-absorbing effects are excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A noise reduction method for the pulse valve of the pulse bag type dust collector. Firstly, the exhaust ports of several pulse valves of the pulse bag type dust collector are connected to the pulse silencer device of the dust collector through the gas pipeline, and the gas is discharged after three-dimensional expansion and resistance noise reduction. , to achieve the purpose of noise reduction.

[0020] The three-dimensional expansion silencer releases the high-pressure gas discharged from the exhaust port of the pulse solenoid valve into a silencer device with a certain capacity to achieve anti-type silencer; and then through the sound elimination of the silencer device itself, it finally realizes noise reduction during discharge and realizes zero emission. noise pollution.

Embodiment 2

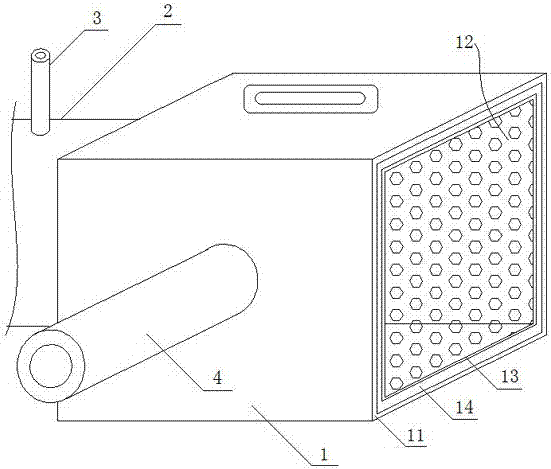

[0022] The dust collector pulse silencer device proposed in Embodiment 1 of the present invention includes a silencer container 1 for three-dimensional expansion of noise reduction, and the silencer container 1 is connected with an air intake expansion pipe 2 and at least one device exhaust port; air intake expansion The pipe 2 is connected to the exhaust port of the pulse valve through the intake pipe 3 .

[0023] The structure of the sound-absorbing container is not specifically limited, such as a cube, a cuboid, a sphere, a polyhedron, etc., as long as there is a three-dimensionally expanded cavity inside.

[0024] However, when the exhaust port of the pulse valve is exhausted, it is directly connected with the intake pipe, which will cause insufficient working pressure of the pulse valve and cannot complete dust removal. Therefore, the intake pipe needs to be connected to the intake expansion pipe first, and then the intake expansion pipe Connect the silencer device so as ...

Embodiment 3

[0026] Such as figure 1 As shown, as a limitation to Embodiment 2, the sound-absorbing container 1 includes a sound-insulating outer layer 11 with a sound-insulating function and a sound-absorbing inner layer 12 with a sound-absorbing function.

[0027] The sound-absorbing inner layer 12 includes a guard plate 13 with a mesh structure located in the innermost layer of the sound-absorbing container, and a sound-absorbing cotton 14 located in the guard plate.

[0028] An exhaust pipe 4 with a sound-absorbing structure is connected to the exhaust port of the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com