Coloring device for 3D (Three Dimensional) printing model

A 3D printing and model technology, applied to the surface coating liquid device, spray device, 3D object support structure, etc., can solve the problems of low coloring efficiency, uneven coloring, rough coloring effect, etc., and achieve faster The effect of coloring speed, uniform mixing of pigments, and improvement of coloring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

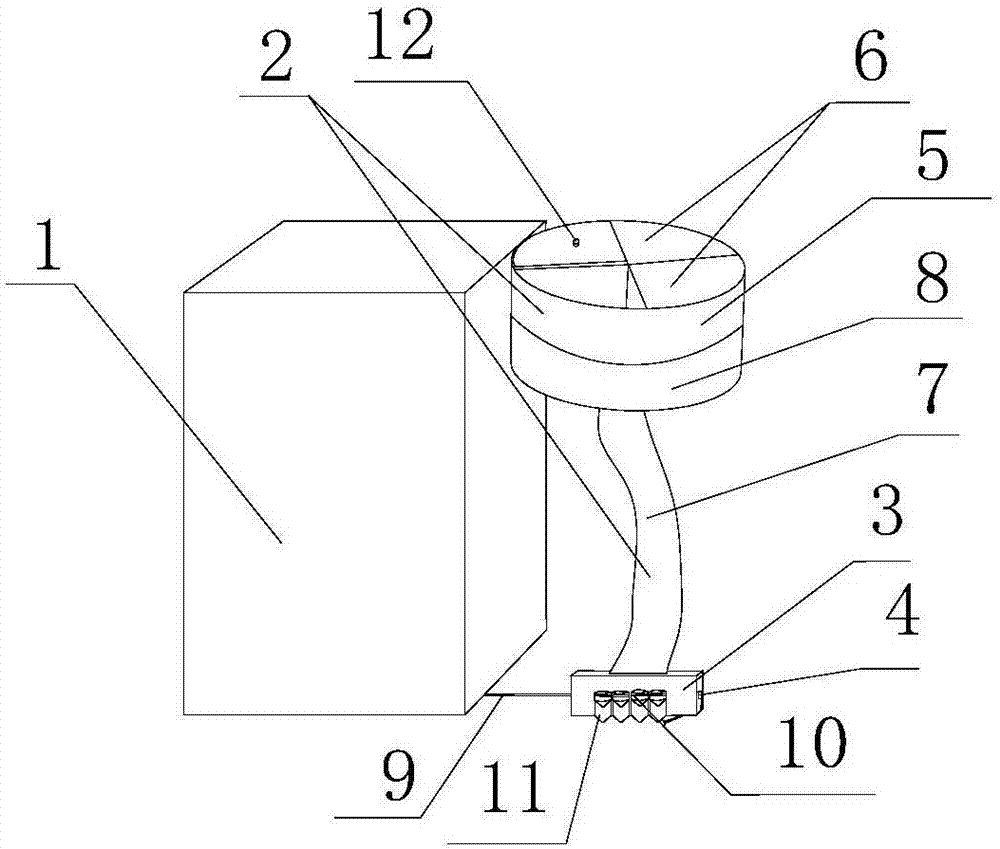

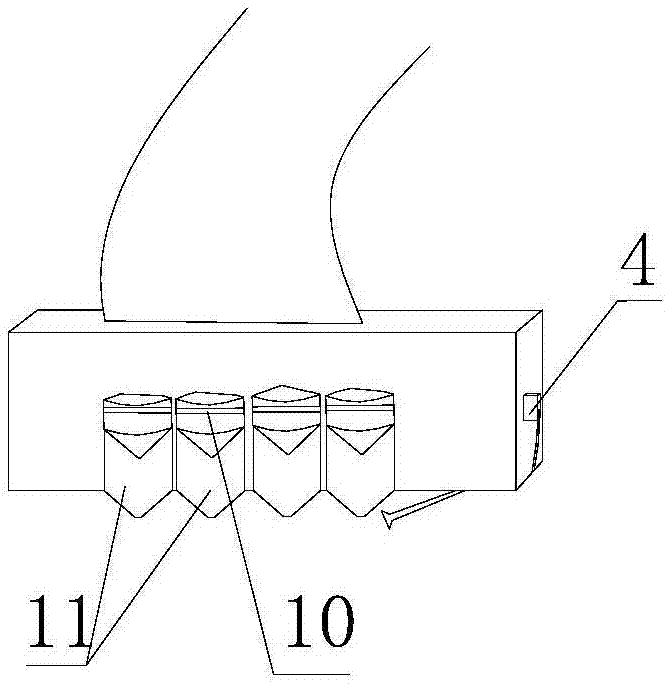

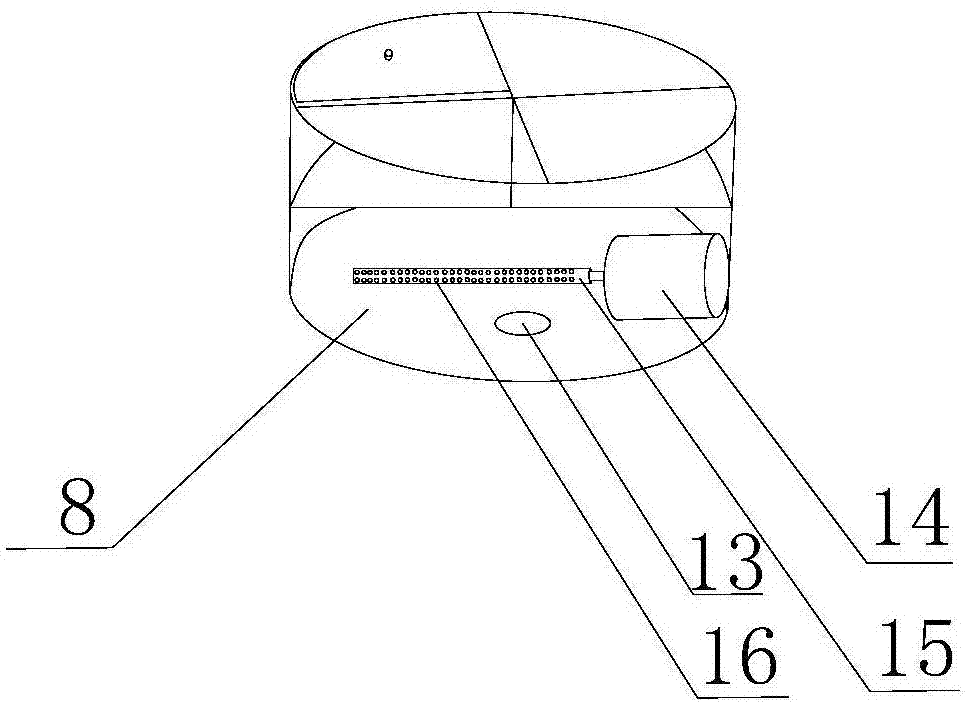

[0026] Such as Figure 1-3 As shown, the coloring device for a 3D printed model is characterized by comprising a mixing device 2, a moving device 1, a spraying device 3, and a drying device 4. The mixing device 2 includes a paint box 5, a tube 7, and The paint box 5 is a polygonal column or cylinder, and one side of the paint box 5 is connected to the top of the mobile device 1. The paint box 5 is provided with a plurality of paint areas 6, which are evenly distributed on the paint box 5. The paint area 6 is provided with multiple colors, the same color of the paint area 6 corresponds to the same paint, a top cover 12 is arranged above the paint area 6, an outlet end is arranged at the bottom of the paint area 6, and an outlet end of the paint area 6 is arranged There is a flow control switch. The outlet end of the paint zone 6 is connected with a mixing chamber 8. A motor 14 is arranged inside the mixing chamber 8. A stirrer 15 is fixed on the rotating shaft of the motor 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com