High-efficient closed energy-saving environment-friendly cleaning tanker of oil well tubing and cleaning method

An energy-saving, environmental-friendly, and car-cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of low steam generation, waste of water sources, and dirty oil and sewage flowing on the ground, and achieves a high degree of automation. , The effect of reducing work intensity and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

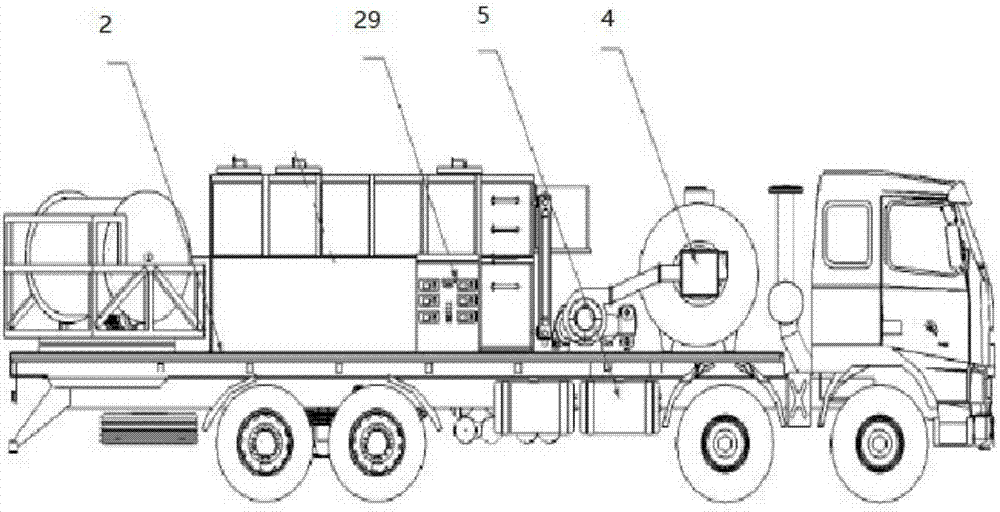

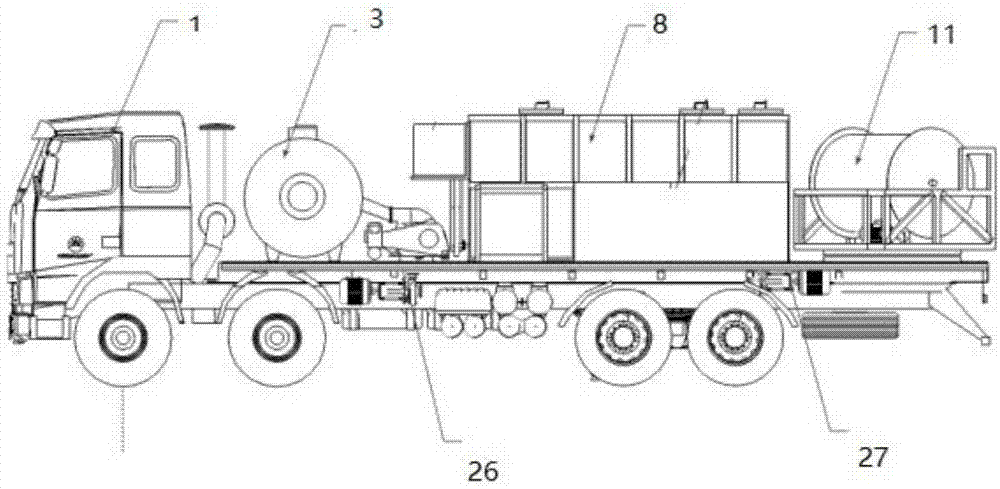

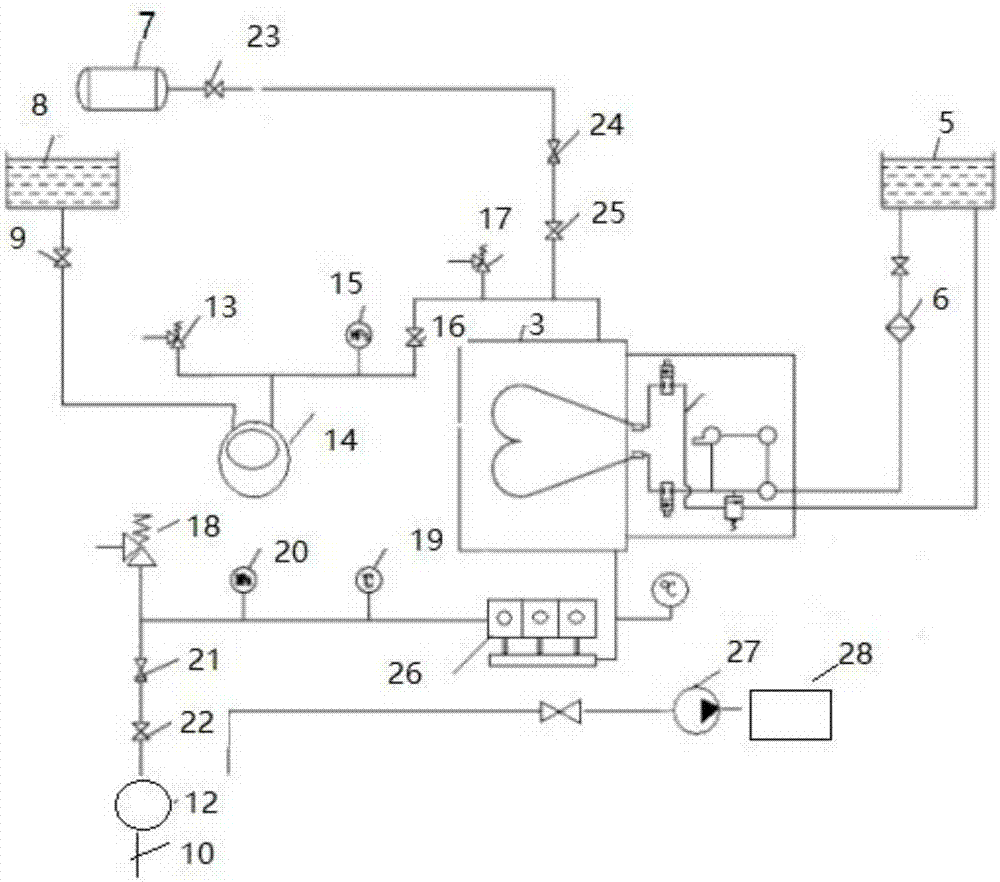

[0025] Attached below Figure 1-3 The high-efficiency airtight, energy-saving, environment-friendly cleaning vehicle and cleaning method for oil well tubing of the present invention are described in detail.

[0026]An efficient airtight, energy-saving, and environment-friendly cleaning vehicle for oil well tubing, characterized in that: the cleaning vehicle includes a vehicle body 1 and an equipment platform 2 arranged on the chassis of the vehicle body, and the equipment platform is provided with a heat source heating component, a water source for supply and recovery Components and automatic control system components, the heat source heating components include a boiler 3, a burner 4 connected to the boiler, a diesel tank 5 connected to the burner and used to provide fuel, a filter connected to the diesel tank 6, the burner is also connected with a gas source gas storage tank 7 for combustion, and the burner is connected with the gas source gas storage tank through a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com