Molding method of nickel base high-temperature alloy low-allowance blades

A technology of nickel-based superalloy and forming method, which is applied in the field of forging, can solve the problems of large die forging blade allowance, high machining cost, and large material consumption, so as to improve productivity, reduce machining allowance, and save metal materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Preliminary basic research

[0020] On the basis of computer simulation, the actual production test results under the cooperation of the shape geometric parameters and thermal processing parameters of billet extrusion, pre-forging and final forging are studied respectively.

[0021] 2. Extrusion, pre-forging size, shape design

[0022] On the basis of determining the basic forging parameters, the size and shape of extrusion and pre-forging can be designed and adjusted by computer simulation technology.

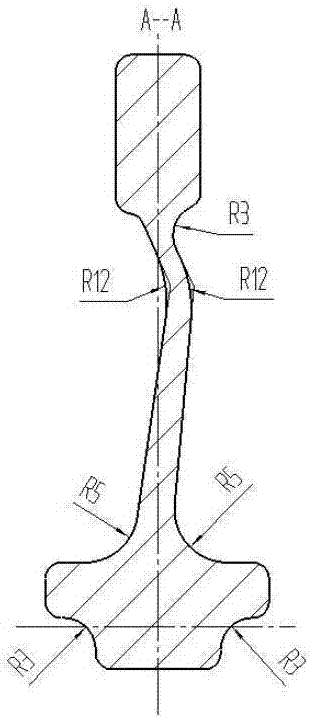

[0023] 3. Small allowance forging of nickel-based superalloy blades

[0024] According to the characteristics of the small margin blade forging of nickel-based superalloy blades in the factory, the final forging die is reasonably designed.

[0025] 4. Formulation of heat treatment process for nickel-based superalloy small margin blades

[0026] For the heat treatment scheme of nickel-based superalloy small margin blades, in view of the comparison with the previous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com