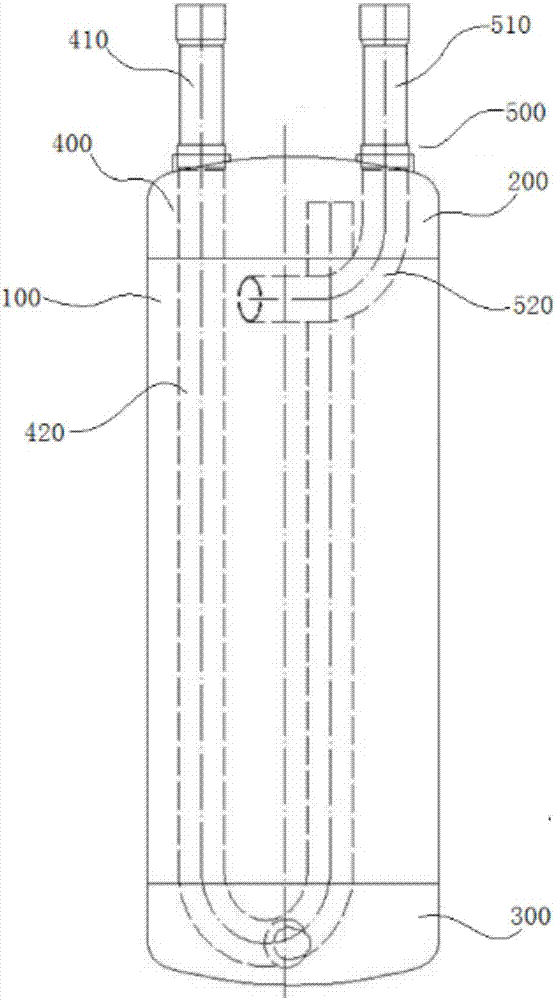

Gas-liquid separator welding fixture and application method thereof

A gas-liquid separator and welding tooling technology, applied in the field of tooling and fixtures, can solve the problems of low positioning accuracy, fixation, and inability to realize the inlet pipe and outlet pipe, etc., and achieve the effect of high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

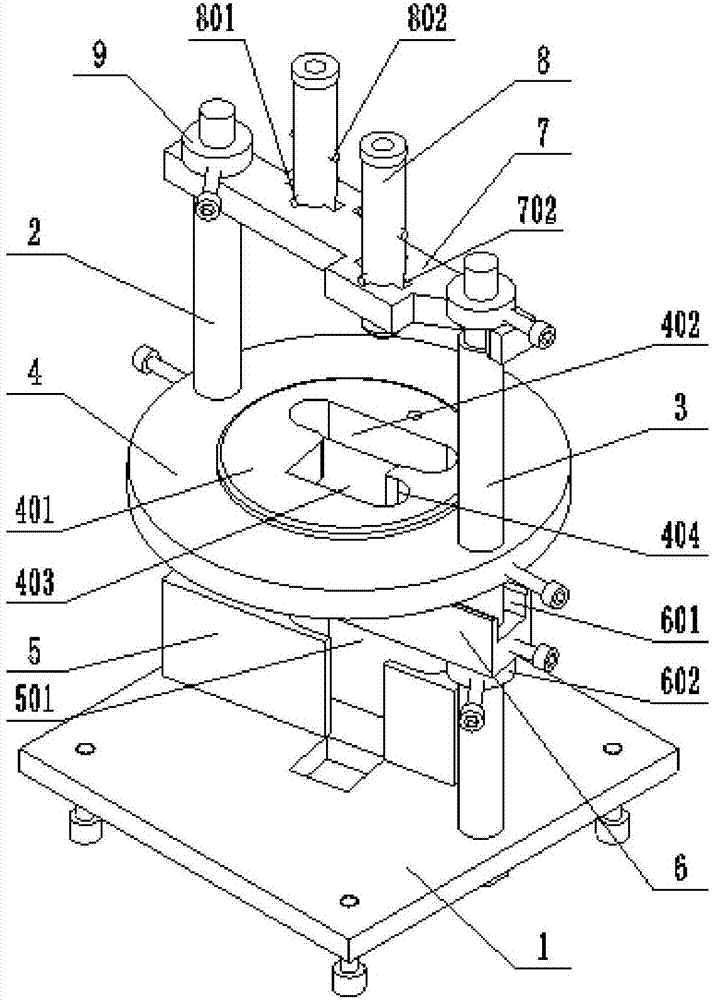

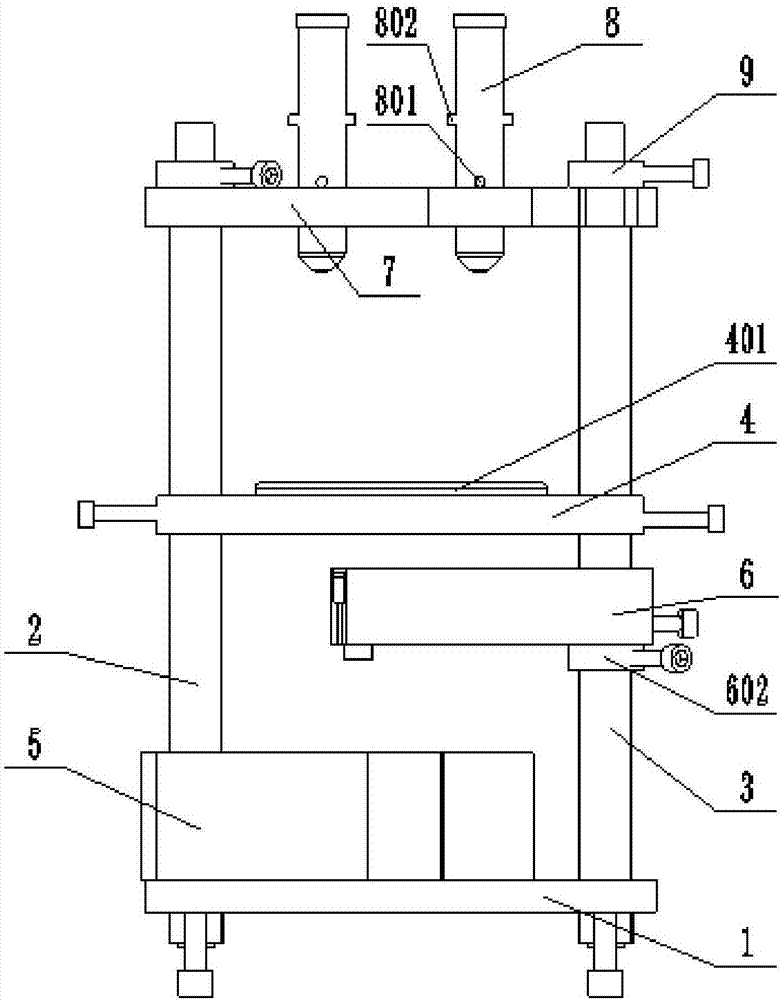

[0052] like figure 2 , image 3 , Figure 4 As shown, this embodiment provides a gas-liquid separator welding tool, which mainly includes a bottom plate 1 , a guide positioning plate 4 , a limit baffle 5 and a support plate 6 .

[0053] Wherein, the bottom four corners of the base plate 1 are respectively provided with a leveling screw for adjusting the flatness of the base plate 1, and the base plate 1 is provided with two vertical cylindrical columns, which are respectively the first column 2 and the second column. Column 3, the lower end of the column is threadedly connected with the base plate 1. The guide positioning plate 4 is provided with two guide holes respectively matched with the two columns, the guide positioning plate 4 is sleeved on the two columns through the guide holes, and the outer side of the guide hole is provided with a connected threaded hole through which the screw passes. The threaded hole can stretch into the guide hole, so that the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com