Nozzle of electrohydrodynamics coaxial-printed polymer metal composite metamaterial

A metal composite and body dynamics technology, applied in the direction of additive processing, coating devices, etc., can solve the problems of unsuitable composite materials and supermaterials, and achieve the effects of easier control, large surface area, and prevention of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

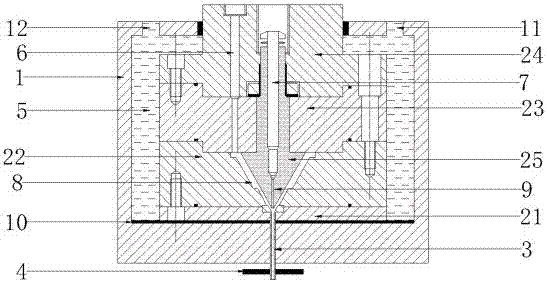

[0021] As shown in the figure, an electrohydrodynamic nozzle for coaxially printing polymer-metal composite metamaterials includes a shell 1, an inner core 2, a nozzle 3, and a high-voltage electrode 4; the inner core 2 is arranged in the shell 1, and the A thermal insulation chamber 5 is formed between the inner core 2 and the outer casing 1, and the outer casing 1 is provided with an insulating liquid inlet 11 and an insulating liquid outlet 12 communicating with the thermal insulation chamber 5; the nozzle 3 is arranged at the center of the bottom of the outer casing 1 and connected to A high-voltage electrode 4; the inner core 2 is formed with a metal melt inlet channel 6, a polymer inlet channel 7, and a metal melt outlet flow channel 8 and a polymer outlet channel 9 respectively pointing to the nozzle 3; the metal melt inlet The channel 6 communicates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com