Production apparatus for producing high-grade fused magnesite from tailings

A production device, fused magnesium technology, applied in the direction of magnesium hydroxide, sustainable manufacturing/processing, chemical industry, etc., can solve the problem of no special grade ore, and achieve the effect of increasing the rate of high-quality products and increasing the yield of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

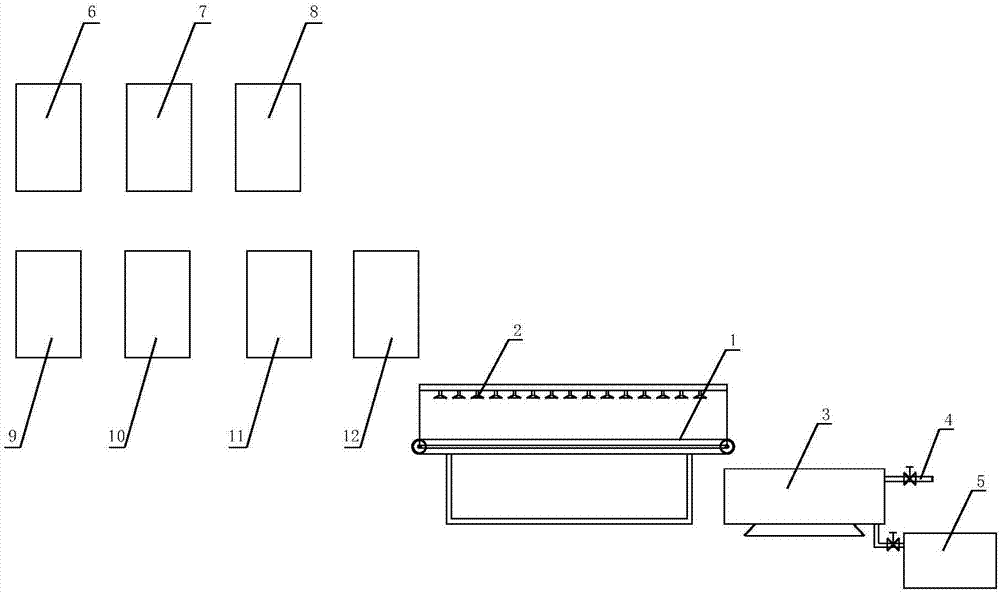

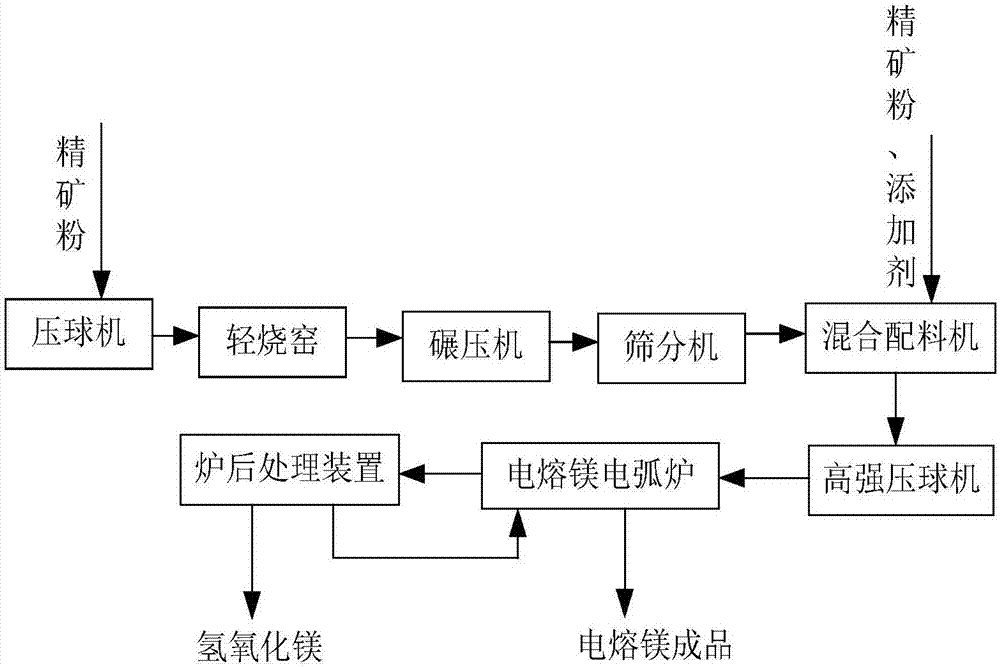

[0019] A production process of a production device for producing high-grade fused magnesium from tailings is completed according to the following steps:

[0020] 1) Feed the concentrated ore powder after flotation of magnesite tailings into the briquetting machine for briquetting and then send it into the light-fired kiln for light-burning at 650°C, and light-burned magnesium oxide powder after rolling;

[0021] 2) Screen the light-burned magnesia powder, finely select the skin sand and under-fired products, and then send them to the mixing batcher to mix and proportion with the concentrate powder and additives after flotation of magnesite tailings, lightly burn and oxidize The ratio of magnesium powder and magnesite tailings flotation concentrate powder and additives is 6:2:0.3, and then sent to the high-strength extrusion ball machine for briquetting to make concentrate balls, and then sent to Inside the fused magnesium electric arc furnace;

[0022] 3) The fused magnesia p...

Embodiment 2

[0026] A production process of a production device for producing high-grade fused magnesium from tailings is completed according to the following steps:

[0027] 1) Feed the concentrated ore powder after flotation of magnesite tailings into the briquetting machine and then into the light-fired kiln at 600°C for light-burning. After rolling, light-burned magnesium oxide powder is obtained;

[0028] 2) Screen the light-burned magnesia powder, finely select the skin sand and under-fired products, and then send them to the mixing batcher to mix and proportion with the concentrate powder and additives after flotation of magnesite tailings, lightly burn and oxidize The ratio of magnesium powder and magnesite tailings flotation concentrate powder and additives is 7:1.5:0.2, and then sent to the high-strength extrusion ball machine for briquetting to make concentrate balls, and then sent to Inside the fused magnesium electric arc furnace;

[0029] 3) The fused magnesia produced by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com