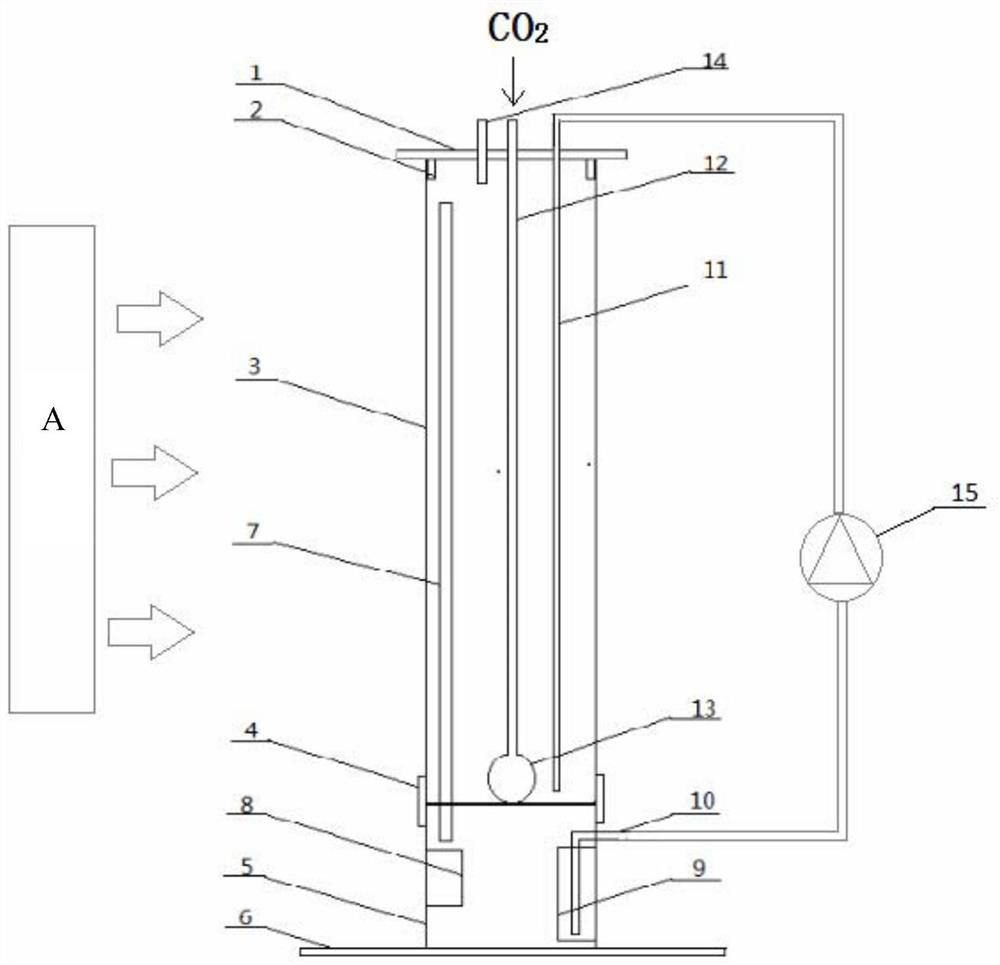

A microalgae culture device and method capable of controlling biological concentration

A technology of microalgae cultivation and concentration, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as increasing production costs, and achieve the effects of improving productivity and optimizing light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

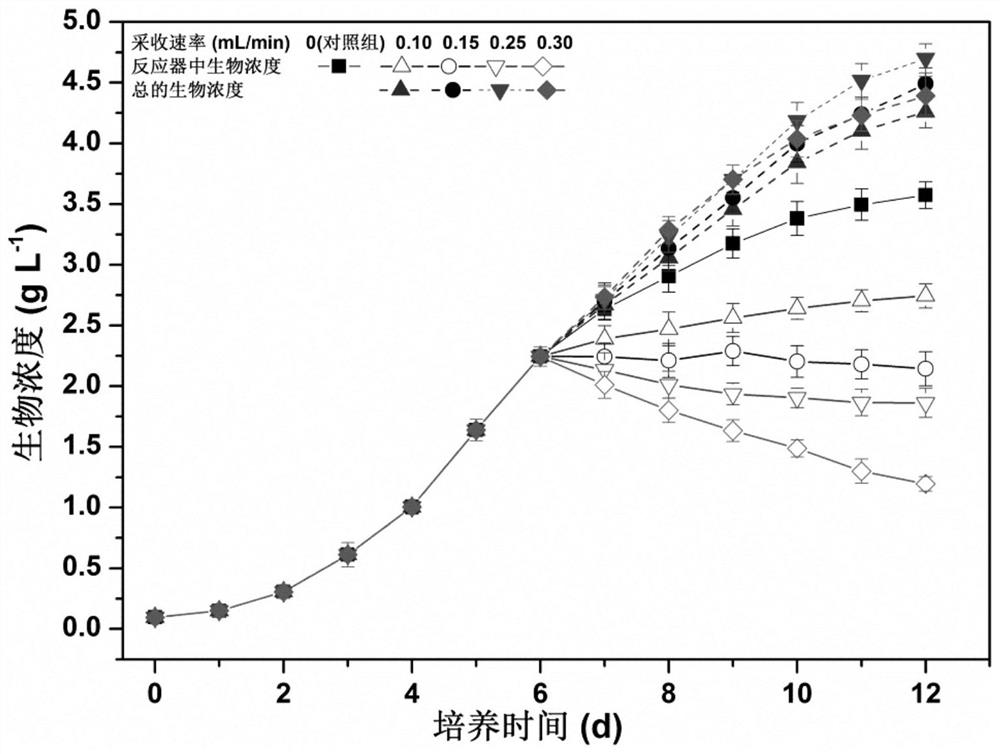

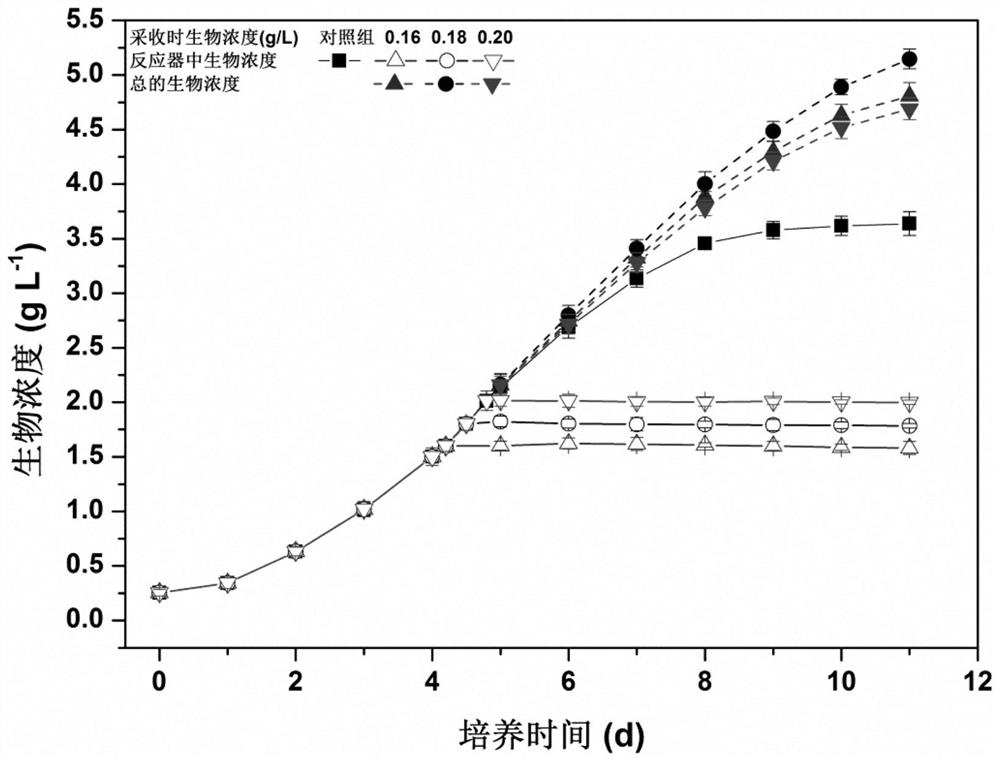

Embodiment 1

[0026] The inoculation amount of Spirulina is 0.0952g L -1 , the concentration reaches 2.245g L -1 Start harvesting when the pump flow rate is 0.10mLmin -1 , after 12 days of cultivation, the total yield of Spirulina reached 4.164g L -1 , Compared with the batch culture without front harvest, the productivity is increased by 19.8%.

Embodiment 2

[0028] The inoculation amount of Spirulina is 0.0952g L -1 , the concentration reaches 2.245g L -1 Start to harvest when the pump flow rate is 0.15mLmin -1 , after 12 days of cultivation, the total yield of Spirulina reached 4.397g L -1 , Compared with the batch culture without front harvest, the productivity is increased by 26.5%.

Embodiment 3

[0030] The inoculation amount of Spirulina is 0.0952g L -1 , the concentration reaches 2.245g L -1 Start harvesting when the pump flow rate is 0.25mLmin -1 , after 12 days of cultivation, the total yield of Spirulina reached 4.604g L -1 , Compared with the batch culture without front harvest, the productivity is increased by 32.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com