Dyeing etching agent for displaying phase change martensite structure in S30432 boiler pipe

An etchant and martensite technology, applied in the field of dyeing etchant, can solve the problems that cannot be observed with an optical microscope and affect the mechanical properties and intergranular corrosion properties of S30432 boiler tubes at room temperature, achieving low cost and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

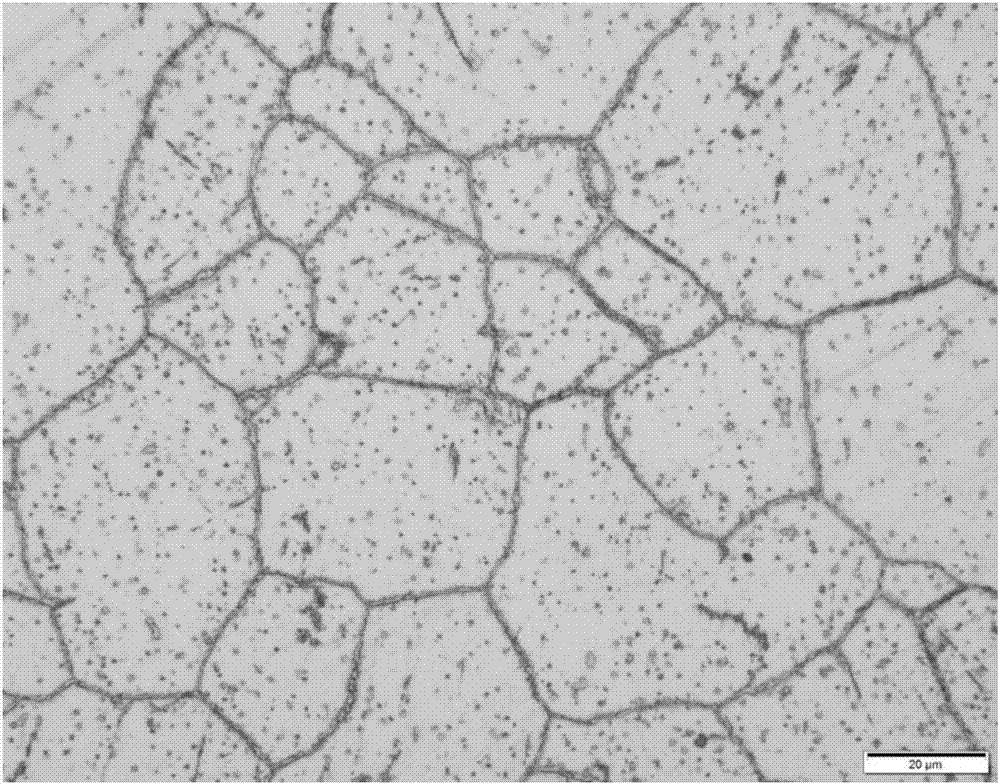

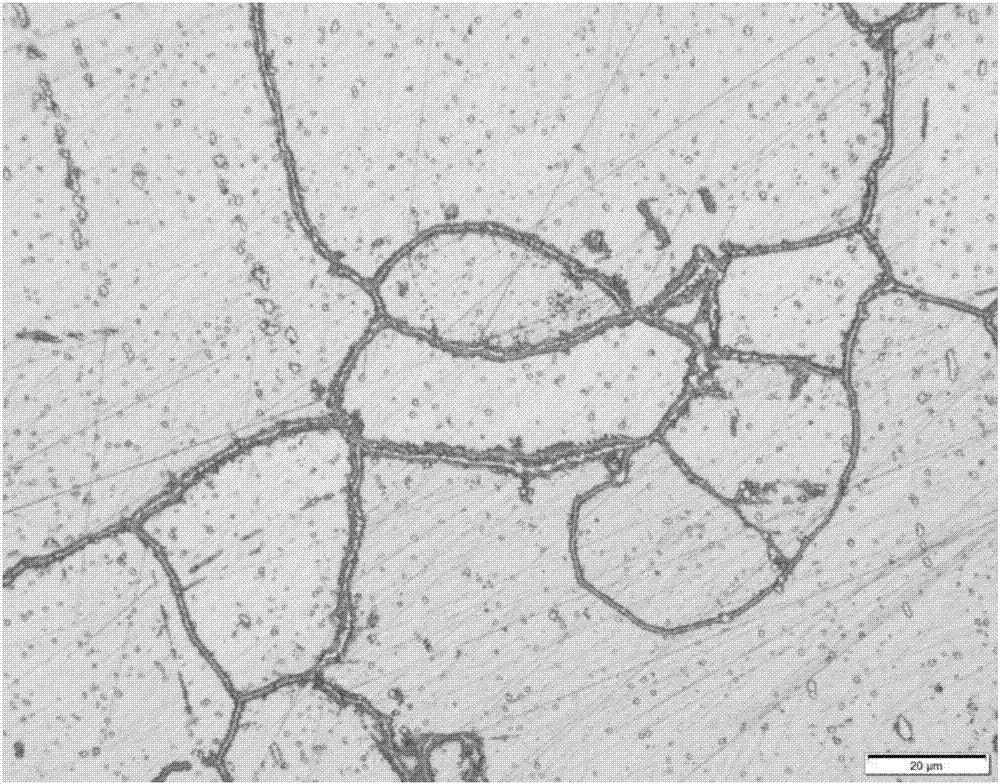

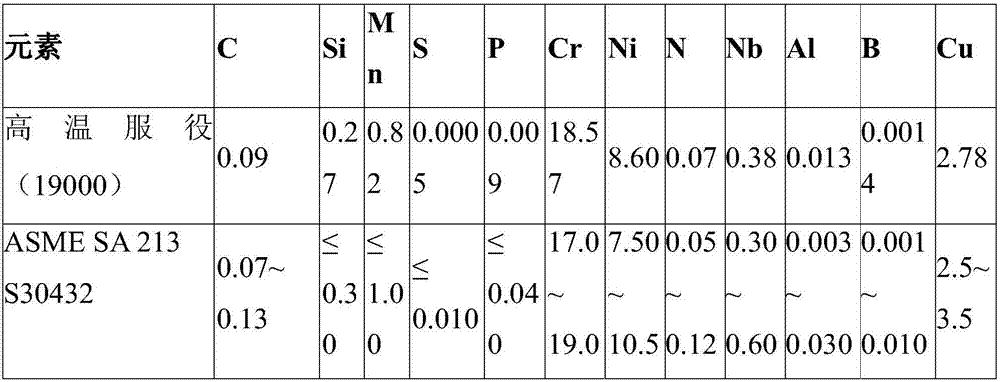

[0014] The invention discloses a dyeing etchant for displaying phase transformation martensite structure in S30432 boiler tubes. The etchant is mixed according to the following formula: sodium pyrosulfite: volume concentration 10% hydrochloric acid = 0.25g: 100ml.

Embodiment 2

[0016] The invention discloses a dyeing etchant for displaying phase transformation martensite structure in S30432 boiler tubes. The etchant is mixed according to the following formula: sodium pyrosulfite: volume concentration 10% hydrochloric acid = 0.5g: 100ml.

Embodiment 3

[0018] The invention discloses a dyeing etchant for displaying phase transformation martensite structure in S30432 boiler tubes. The etchant is mixed according to the following formula: sodium pyrosulfite: volume concentration 10% hydrochloric acid = 1.0g: 100ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com