A Partial Potting Process Method for Preventing Device Leakage

A process method and device technology, which are applied in the field of safety and reliability of electronic components, can solve the problems of lead leakage, insulation decline of leads with too small spacing, leakage current, etc. Control, good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

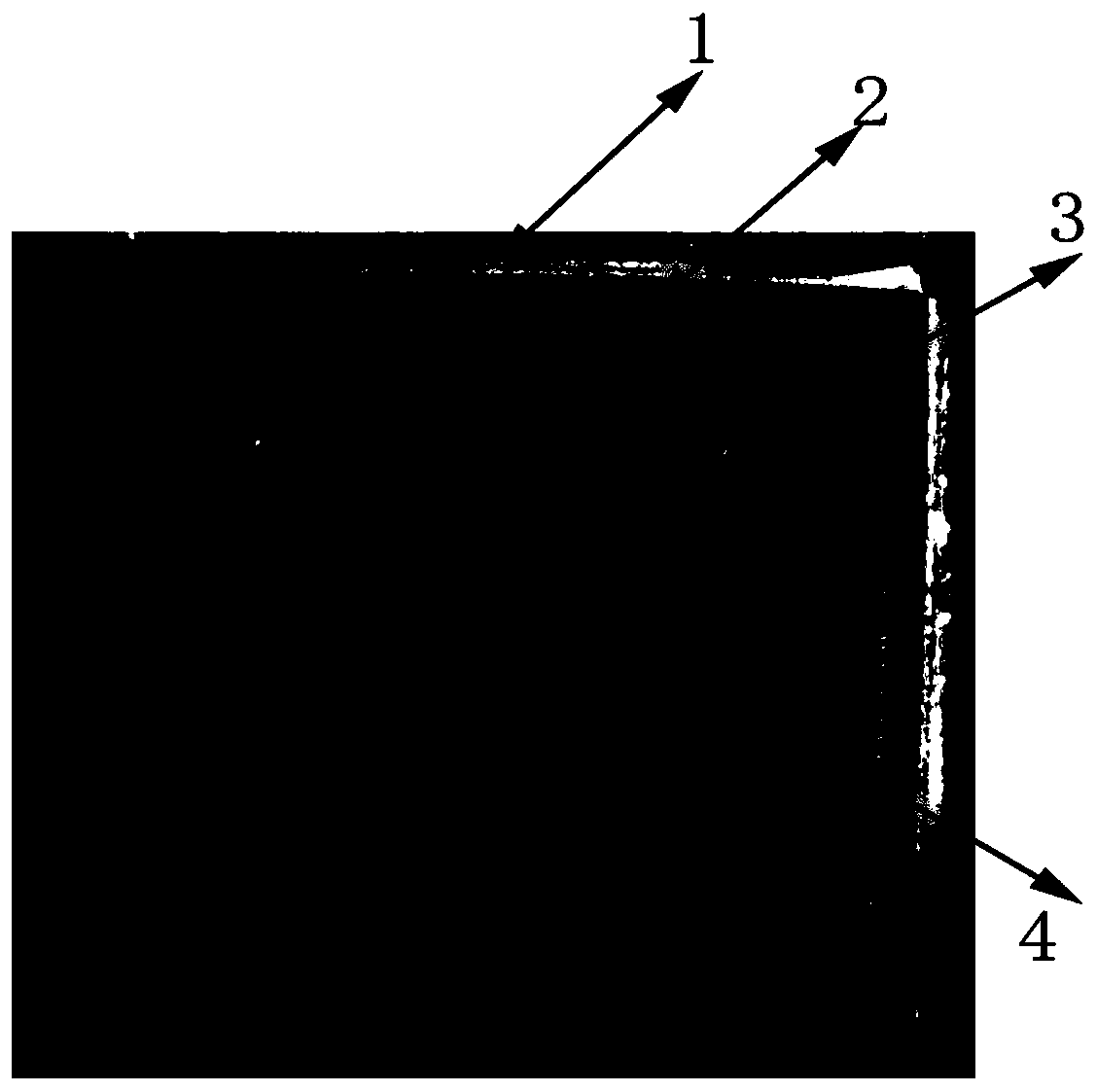

[0029] The existing three-defense protection of printed circuit board assemblies in aerospace and military electronic products mainly adopts the process of coating protective coatings. However, after using this method to protect some devices with a lead spacing of less than 0.5mm, it is insufficient for water vapor and humidity environments. Leading to problems such as insulation drop and leakage between leads with too small pitch.

[0030] The protective ability of the protective layer against water vapor is mainly reflected in two aspects, one is the compactness of the protective layer, the denser the protective layer, the better the protective performance; the other is the thickness of the protective layer, the greater the thickness, the better the protective performance. Most of the protective layers used in electronic products are organic substances with large intermolecular gaps, H 2 O is a small molecule, which can easily penetrate into the organic protective layer. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com