A kind of stripping method of weaving material for wicker

A weaving material and cleaning agent technology, applied in the field of wicker handicrafts, can solve the problems of unsatisfactory peeling machine effect, large time and labor consumption, cracking, etc., achieve high bone-skin separation efficiency, improve fresh skin peeling rate, reduce The effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

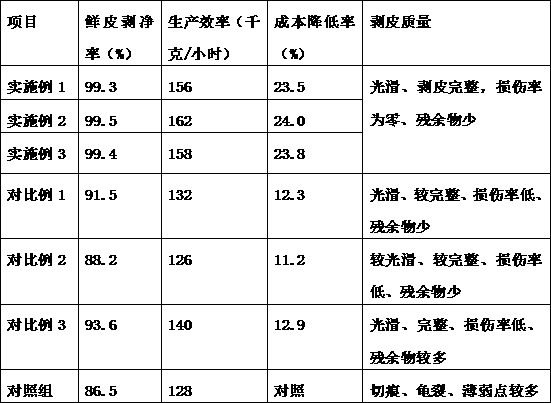

Examples

Embodiment 1

[0015] A peeling method of braided material for wicker, comprising the following steps:

[0016] (1) After removing the side branches and leaves of the fresh braided materials, evenly stagger the head and tail, bundle them into small bundles, each bundle has a diameter of 20 cm, put the bundles into the pool, and add 0.02% of the water volume in the pool Quicklime, stir well, soak for 15 minutes and remove;

[0017] (2) Disperse the bundled braided materials that have been pulled out, and put them into bubbling water at a temperature of 40°C while they are hot. The bubbling water is made of the following ingredients in parts by weight: 15 parts of saponins, 13 parts of sesame leaves, Soak 8 parts of Sapinberry, 6 parts of Thoreau, 5 parts of Chinese tallow tree bark, and 700 parts of water, soak in sparkling water for 6 hours, remove and control the water for 40 minutes;

[0018] (3) Uncover the braided material after water control from both ends, and put the peeled braided m...

Embodiment 2

[0022] A peeling method of braided material for wicker, comprising the following steps:

[0023] (1) After removing the side branches and leaves of the fresh braided materials, evenly stagger the head and tail, bundle them into small bundles, each bundle has a diameter of 25 cm, put the bundles into the pool, and add 0.03% of the water volume in the pool Quicklime, after stirring evenly, soak for 18 minutes and remove;

[0024] (2) Disperse the bundled braided materials that have been pulled out, and put them into bubbling water at a temperature of 45°C while they are hot. The bubbling water is made of the following ingredients in parts by weight: 18 parts of saponins, 14 parts of sesame leaves, Soak 9 parts of Soapberry, 7 parts of Solo fruit, 6 parts of Chinese tallow bark, and 750 parts of water, soak in sparkling water for 7 hours, remove and control the water for 50 minutes;

[0025] (3) Uncover the braided material after water control from both ends, and put the peeled ...

Embodiment 3

[0029] A peeling method of braided material for wicker, comprising the following steps:

[0030] (1) After removing the side branches and leaves of the fresh braided materials, evenly stagger the head and tail, bundle them into small bundles, each bundle has a diameter of 30 cm, put the bundles into the pool, and add 0.04% of the water volume in the pool Quicklime, stir well, soak for 20 minutes and remove;

[0031] (2) Disperse the bundled braided materials that have been pulled out, and put them into bubbling water at a temperature of 50°C while they are hot. The bubbling water is made of the following ingredients in parts by weight: 20 parts of saponins, 15 parts of sesame leaves, 10 parts of Sapinberry, 8 parts of Thoreau fruit, 7 parts of Chinese tallow tree bark, 800 parts of water, soak in sparkling water for 8 hours, remove and control the water for 60 minutes;

[0032] (3) Uncover the braided material after water control from both ends, and put the peeled braided mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com