A kind of glass plate tempering process control method

A technology of process and control method, applied in glass tempering, program control, glass manufacturing equipment, etc., can solve problems such as heating furnace temperature error, achieve stable production process and product quality, improve finished product quality, and avoid insufficient wind pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

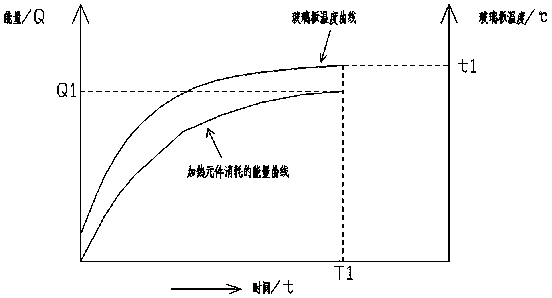

[0025] Such as figure 1 As shown, the executive mechanism is a driving mechanism that controls the glass plate out of the furnace, and the control process of the heating control method of the present invention is as follows:

[0026] First, get the total mass of the glass plate to be heated, according to the formula q 0 =cm△t Calculate the energy q needed to heat the glass plate from the temperature when it enters the furnace to the temperature when it comes out of the furnace 0, Among them, c is the specific heat capacity of the glass plate, m is the total mass of the glass plate to be heated, and Δt is the temperature difference between the glass plate entering the furnace temperature and the glass plate leaving the furnace temperature. The furnace temperature refers to the temperature set when the glass plate is heated in the heating furnace until it softens in the tempering process of the glass plate and meets the conditions for the furnace to be released. Usually, the v...

Embodiment 2

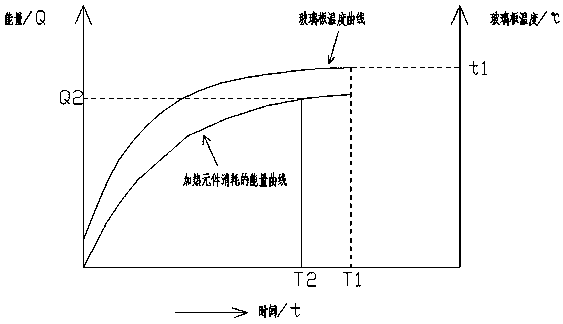

[0032] Such as figure 2 As shown, the executive mechanism is the control mechanism of the cooling fan, and the control process of the control method of the present invention is as follows:

[0033] First, get the total mass of the glass plate to be heated, according to the formula q 0 =cm△t Calculate the energy q needed to heat the glass plate from the temperature when it enters the furnace to the temperature when it comes out of the furnace 0, Among them, c is the specific heat capacity of the glass plate, m is the total mass of the glass plate to be heated, and Δt is the temperature difference between the glass plate entering the furnace temperature and the glass plate leaving the furnace temperature. The furnace temperature refers to the temperature set when the glass plate is heated in the heating furnace until it softens in the tempering process of the glass plate and meets the conditions for the furnace to be released. Usually, the value range of the furnace temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com