Composite aggregate water-permeable concrete and preparation method thereof

A technology of permeable concrete and concrete, which is applied in ceramic products, other household utensils, applications, etc. It can solve the problems of not being able to wrap aggregates well and cement slurry sinking to the bottom, and achieve good economic benefits, weight reduction, and good corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing composite aggregate permeable concrete; it is characterized in that it comprises the following steps:

[0029] Step 1, prepare materials: prepare materials according to the designed ratio of each material;

[0030] Step 2, Pre-configure the aggregate: Mix the crushed stone, pumice, and recycled concrete aggregate evenly;

[0031] Step 3, aggregate improvement treatment: add water to the mixture obtained in step 2, the amount of water is 75% of the water consumption required for the crushed stone and recycled concrete to achieve the required water absorption rate, and perform pre-improvement treatment on the aggregate, Control the amount of additional water should not be too much to make the aggregate moist;

[0032] Step 4, aggregate and gel material mixing: Add the gel material required for environment-friendly composite aggregate concrete to the mixture obtained in step 2 for stirring. The gel material is fly ash and cement, and the mixing is c...

specific Embodiment

[0035] Five kinds of specific embodiments of the present invention are provided below, and the parts by weight of each component of five kinds of specific embodiments are as shown in Table 1,

[0036] Table 1: Components used in each embodiment and their consumption (unit / weight part)

[0037] Example

gravel

pumice

recycled concrete

cement

water

1

0.35

806

169

210

435

109

190

2.2

2

0.27

671

211

263

530

94

168

2.5

3

0.31

448

281

350

540

60

139

2.4

4

0.27

806

169

210

426

107

107

2.0

5

0.31

671

211

263

464

51

119

2.1

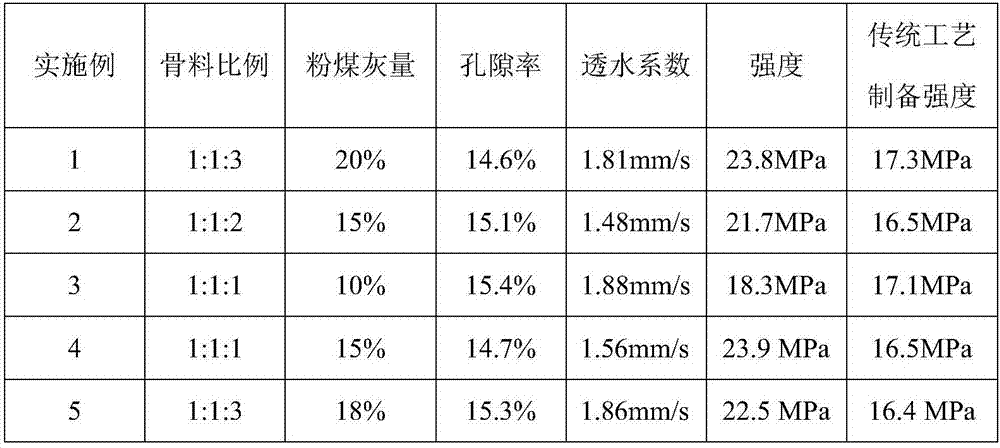

[0038] Table 2: Each process intensity of five kinds of embodiments

[0039]

[0040] It can be seen from the above table that the strength of Example 1 is the highest, but the porosity and water permeability coefficient are a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap