Method for cross distillation separation of C13-16 n-alkanes in liquid wax oil

A technology for separation of n-paraffins and rectification, applied in distillation purification/separation, organic chemistry, etc., can solve the problems of low product purity and yield, cumbersome operation, high energy consumption in separation process, and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

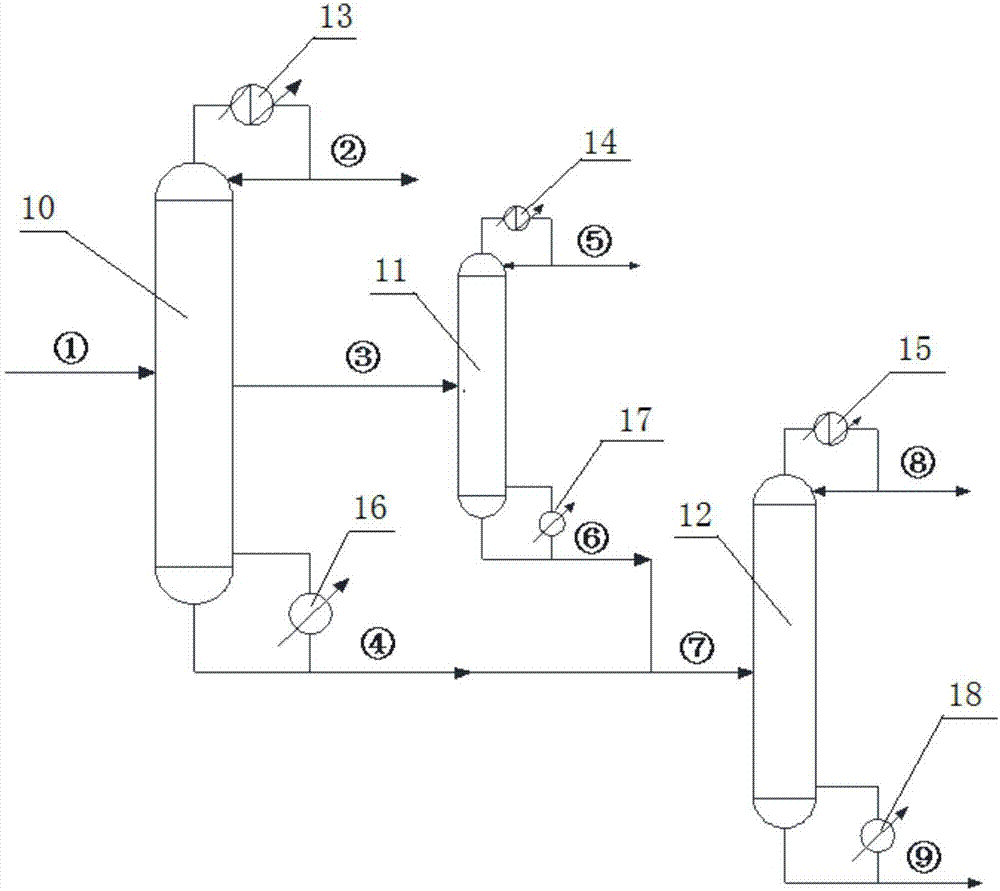

[0028] C in a kind of cross rectification separation liquid wax oil of the present invention 13-16 Processes for n-paraffins, as attached figure 2 Shown:

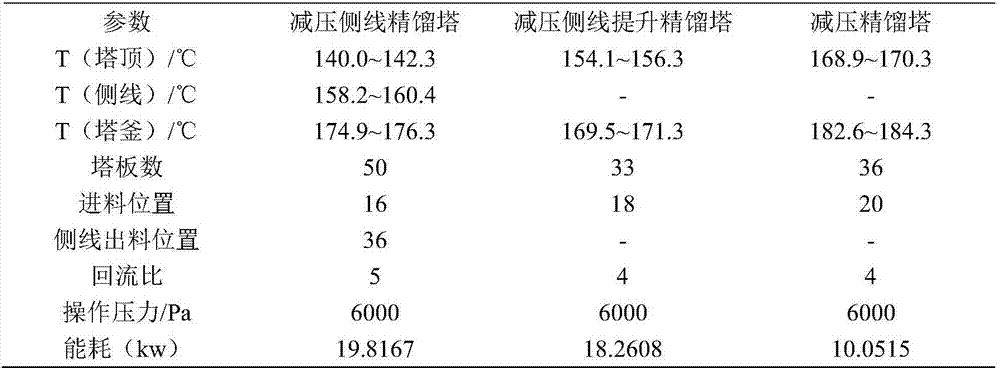

[0029] (1) Raw material ① is added from the 16th block of the vacuum side line rectification tower 10, and the pressure of the control tower is 0.006MPa. ~176.3°C, the reflux ratio is controlled to be 5:1. After separation, n-tridecane is obtained from the top of the tower ②, and the mass content and yield reach 99.61% and 99.56% respectively. The side line ③ is n-tetradecane and n-pentadecane fractions. The bottom of the tower ④ is n-pentadecane and n-hexadecane cuts;

[0030] (2) The side stream distillate is sent to the vacuum side stream lifting rectification tower 11 for separation, and the temperature at the top and bottom of the tower is controlled to be 154.1-156.3°C and 169.5-171.3°C respectively, and the reflux ratio is 4:1. The top of the tower ⑤ is obtained n-tetradecane, the mass content and yield reach 99....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com