Improved type production technology of high-magnetic-inductivity non-orientation silicon steel sheet

A technology of oriented silicon steel and production process, which is applied in the field of production process of improved high magnetic induction non-oriented silicon steel sheet, can solve the problems of high production cost, low magnetic induction of silicon steel sheet, low production efficiency, etc., and achieve the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

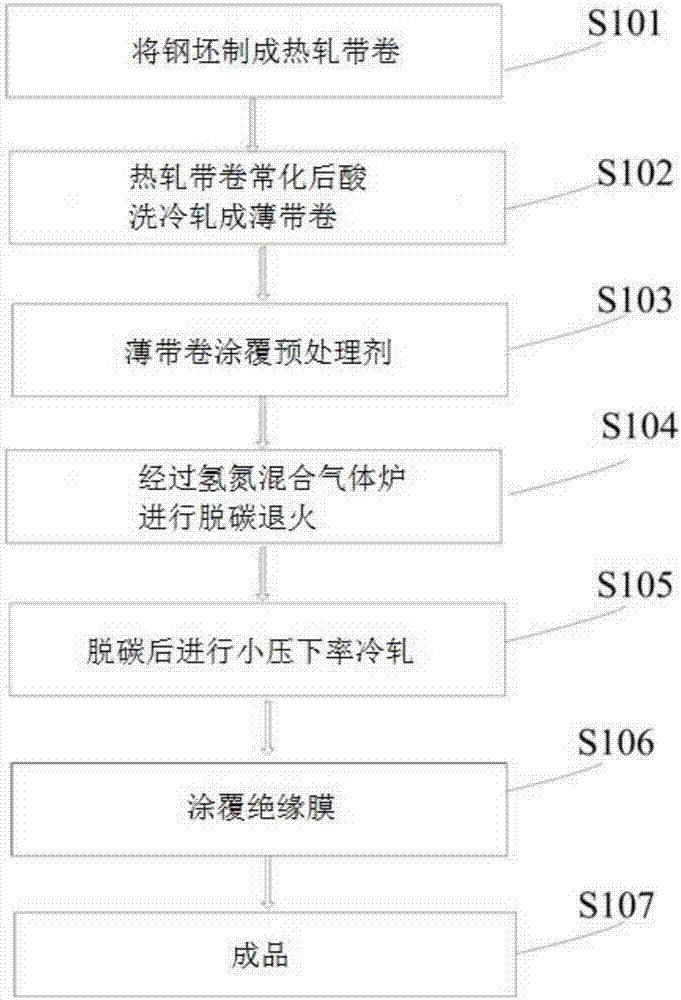

Image

Examples

Embodiment 1

[0044] Raw materials: hot-rolled coils made of Q235 steel billet.

[0045] Normalizing treatment: heat the hot-rolled steel strip to 800°C for 40 minutes.

[0046] After pickling, it is cold-rolled into thin coils with a thickness of 0.50mm, and the composition is: C<0.12%, Si<0.31%, Mn<0.11%, P<0.025%, S<0.025%, Al<0.04%;

[0047] Pretreatment agent: a concentration of 18% sulfurized silicate aqueous solution;

[0048] Protective gas: 60% nitrogen + 23% hydrogen

[0049] Decarburization annealing: Put the cold-rolled steel plate coated with the pretreatment agent into a hydrogen-nitrogen mixed gas furnace for annealing and decarburization annealing. The annealing temperature is 830 degrees, and the time in the furnace is 6 minutes. Atmosphere dew point temperature is 40°C

[0050] Detection: the C content in the steel plate is reduced to 49.9ppm, and the magnetic properties of the obtained high magnetic induction silicon steel sheet are: P15=5.20W, B50=1.90T.

Embodiment 2

[0052] Raw materials: hot-rolled coils made of Q235 steel billet.

[0053] Normalizing treatment: heat the hot-rolled steel strip to 850° C. for 60 minutes.

[0054] After pickling, it is cold-rolled into a thin coil with a thickness of 0.45mm, and the composition is: C<0.14%, Si<0.30%, Mn<0.12%, P<0.025%, S<0.025%, Al<0.04%;

[0055] Pretreatment agent: a 30% sulfurized silicate aqueous solution;

[0056] Protective gas: 55% nitrogen +30% hydrogen;

[0057] Decarburization annealing: Put the cold-rolled steel plate coated with the pretreatment agent into a hydrogen-nitrogen mixed gas furnace for annealing and decarburization annealing. The annealing temperature is 850 degrees, and the annealing (holding) time is 1.5 hours.

[0058] Detection: the C content in the steel plate is reduced to 50ppm, and the magnetism of the obtained high magnetic induction silicon steel sheet is: P15=5.22W, B50=1.91T.

[0059] The verification results show that the method improves the magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com