Method for resourcefully utilizing black copper mud by copper electrolysis

A technology of black copper mud and recycling, applied in the direction of improving process efficiency, etc., can solve the problems of inability to form open circuits, high cost, pollute the environment, etc., and achieve the effect of solving the problem of open circuits

Active Publication Date: 2017-11-24

JIANGXI COPPER

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Returning to the smelting of the fire system makes impurities such as arsenic, antimony, and bismuth circulate and enrich in the system, and cannot form an open circuit; arsenic is easy to enter the atmosphere during oxidation and roasting, which seriously pollutes the environment and endangers the health of operators; the leaching electrolysis method uses sulfide to fix arsenic The plan does not solve the problem of arsenic utilization

[0004] More importantly, in the current black copper slime treatment method, the valuable elements rich in black copper slime are not fully recovered, and the arsenic damage control has not realized resource utilization, resulting in high cost and serious secondary pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

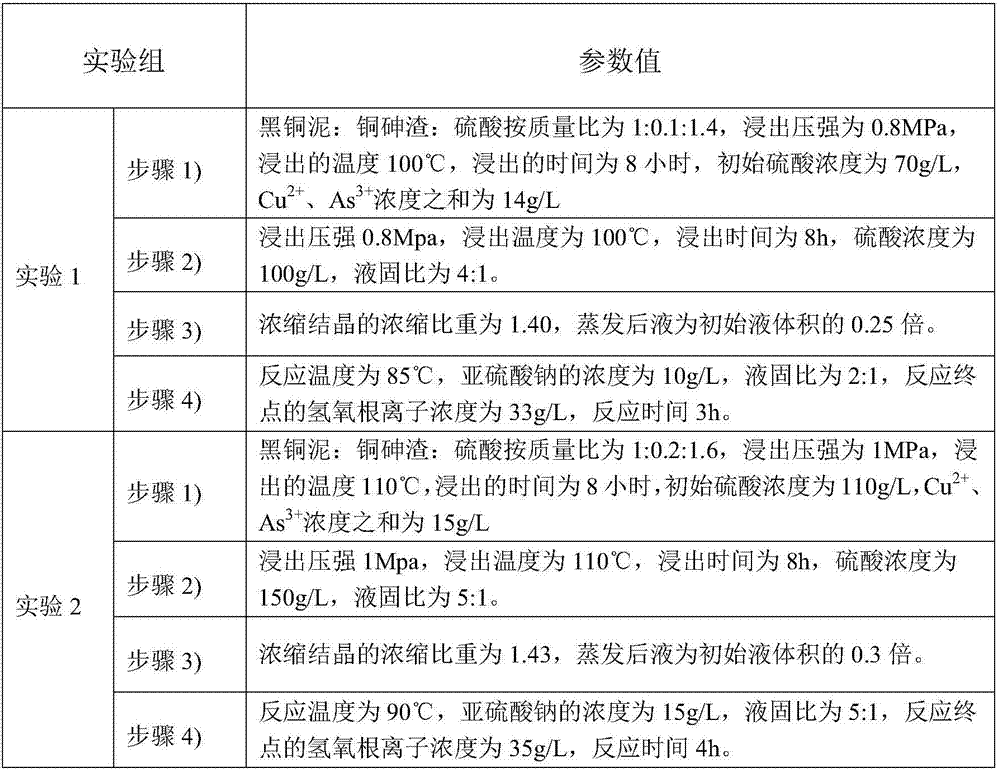

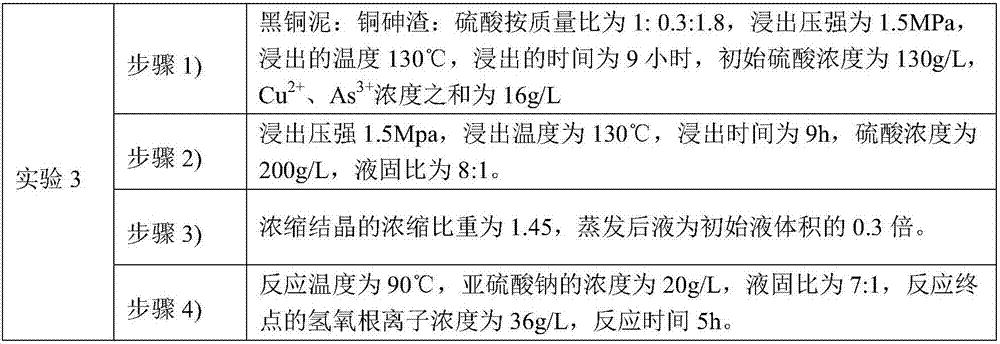

Embodiment 1~3

[0028] Carry out three groups of tests according to the above method, embodiment 1 corresponds to experiment 1, embodiment 2 corresponds to experiment 2,

Embodiment 3

[0029] Example 3 corresponds to Experiment 3. The test parameters of each group of tests are shown in Table 1:

[0030] Table 1

[0031]

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

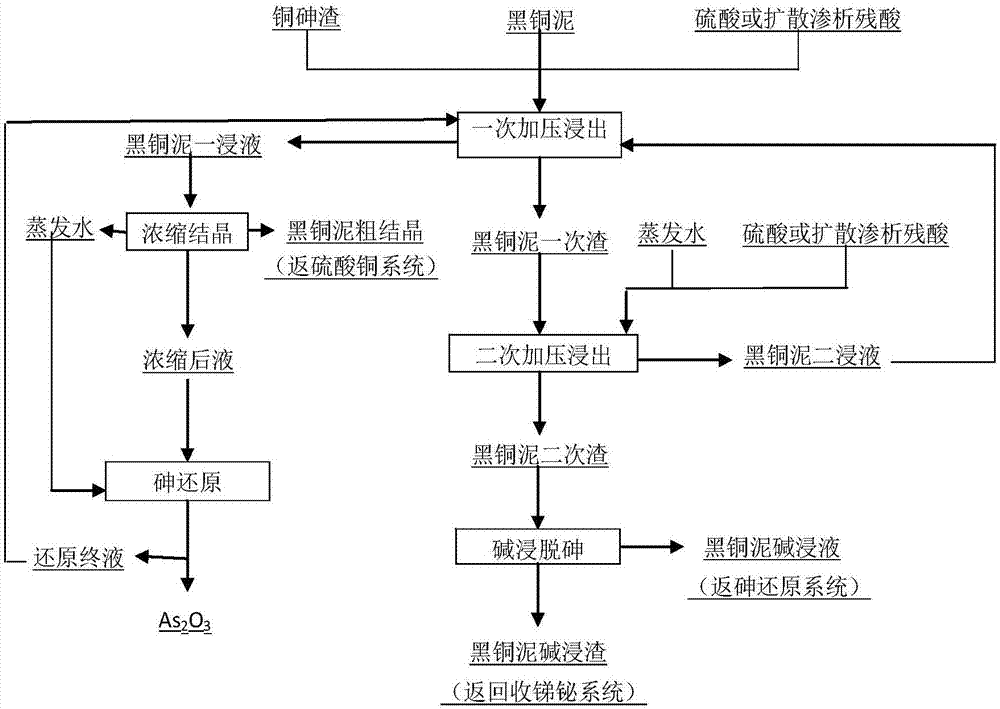

The invention discloses a method for resourcefully utilizing black copper mud by copper electrolysis. The method comprises the steps: (1) primary pressure leaching of black copper mud; (2) secondary pressure leaching of black copper mud; (3) condensation crystallization; (4) alkali leaching and arsenic removal; (5) arsenic reduction. The method adopts primary pressure leaching, secondary pressure leaching, alkali leaching and arsenic removal of secondary leaching residues, condensation crystallization of primary leaching liquid, merging concentrated liquid with secondary leaching arsenic and alkali leaching liquid to reduce and move arsenic as a trunk process to process the black copper mud, therefore realizing effective separation of copper, arsenic, antimony and bismuth, and solving the problem of opening treatment of the black copper mud. Valuable elements such as copper, antimony, bismuth, nickel and arsenic in the black copper mud are effectively and comprehensively recovered, arsenic pollution governance realizes resourceful utilization, and the severe secondary pollution of hazardous solid wastes is avoided.

Description

technical field [0001] The invention belongs to the technical field of element recovery and utilization, and in particular relates to a method for resource utilization of copper electrolytic black copper slime. Background technique [0002] Black copper sludge is a by-product of the electrolyte purification process in the copper electrolytic refining process, which not only contains copper (50-55%), arsenic (20-30%) and other impurities, but also contains a small amount of antimony, bismuth and other elements. Listed as hazardous solid waste by the state. [0003] The existing electrolytic black copper slime treatment methods mainly include: return fire system smelting method, oxidation roasting leaching method, leaching electrolysis method, etc. Returning to the smelting of the fire system makes impurities such as arsenic, antimony, and bismuth circulate and enrich in the system, making it impossible to form an open circuit; arsenic is easy to enter the atmosphere during o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B7/00C22B30/04C22B15/00C22B23/00C22B30/02C22B30/06

CPCC22B7/007C22B7/008C22B15/0056C22B23/0407C22B30/02C22B30/04C22B30/06Y02P10/20

Inventor 胡建辉刘永平吴新明赵海涛蒋震清周宇飞郑春到吴晓莉张玲玲黄冰

Owner JIANGXI COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com