A kind of protective paper and preparation method thereof

A technology of face-protecting paper and wood fiber, which is applied in papermaking, paper, textiles and paper-making, etc., can solve the problems of poor bonding between face-protecting paper and gypsum board, low paper strength, and easy delamination, so as to avoid air bubbles Effects of layering, strength improvement, and air permeability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

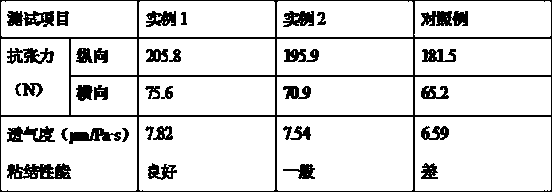

Examples

example 1

[0012] Take 500g of mustard seeds and 2L of water into a beaker, move the beaker into a water bath, control the temperature of the water bath at 40°C, keep warm and heat for 14 hours, take out the mustard seeds and put them in an oven, and dry them at 95°C until the mustard seeds contain water The rate is 8%. Put the dried mustard seeds in a pulverizer and pulverize them for 20 minutes to obtain pulverized products. Put the pulverized materials into an oil press and squeeze out the oil at 120°C to obtain crude mustard oil. Crude mustard seeds The oil was filtered to obtain the filtrate. Take 40mL of the filtrate and 200mL of absolute ethanol and add them to a three-necked flask equipped with a thermometer and a reflux device. Move the three-necked flask into a water bath, control the temperature of the water bath to 85°C, stir and mix for 5 minutes, and then add the three-necked flask to the three-necked flask. Add 3g of tert-butyl hydroperoxide into the flask, stir and react f...

example 2

[0014] Take 500g of mustard seeds and 2L of water into a beaker, move the beaker into a water bath, control the temperature of the water bath at 40°C, keep warm and heat for 14 hours, take out the mustard seeds and put them in an oven, and dry them at 95°C until the mustard seeds contain water The rate is 8%. Put the dried mustard seeds in a pulverizer and pulverize them for 20 minutes to obtain pulverized products. Put the pulverized materials into an oil press and squeeze out the oil at 120°C to obtain crude mustard oil. Crude mustard seeds The oil was filtered to obtain the filtrate. Take 40mL of the filtrate and 200mL of absolute ethanol and add them to a three-necked flask equipped with a thermometer and a reflux device. Move the three-necked flask into a water bath, control the temperature of the water bath to 85°C, stir and mix for 5 minutes, and then add the three-necked flask to the three-necked flask. Add 3g of tert-butyl hydroperoxide into the flask, stir and react f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com