Pulp layer paper for high-speed battery production line produced by k8 cable paper and preparation method

A technology for pulp layer paper and cable paper, which is applied in the field of dry battery manufacturing, can solve the problems of pulp layer paper rupture, difficulty in feeding zinc can, powder drop, etc., and achieves improved smoothness and elasticity, good static electricity removal effect, and good mechanical applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]This embodiment adopts K8 cable paper to produce pulp paper for high-speed battery production line (≥800 pieces / min), the base paper of this pulp paper adopts K8 cable paper, and a coating layer is coated on one side of the base paper. When preparing the cloth layer, weigh each component according to the following formula:

[0036]

[0037] The instant glue in the above formula is composed of instant glue silk 100-27H and instant glue silk 100-37H produced by Hunan Xiangwei Co., Ltd. with a mass ratio of 14:16; the modified starch is produced by Foshan Huahao Huafeng Starch Co., Ltd. Composition of cross-linked starch JLS and etherified starch H315 with a mass ratio of 25:20; the composite corrosion inhibitor is composed of bismuth trichloride and EDTA, and the weight ratio of bismuth trichloride and EDTA is 3:1.

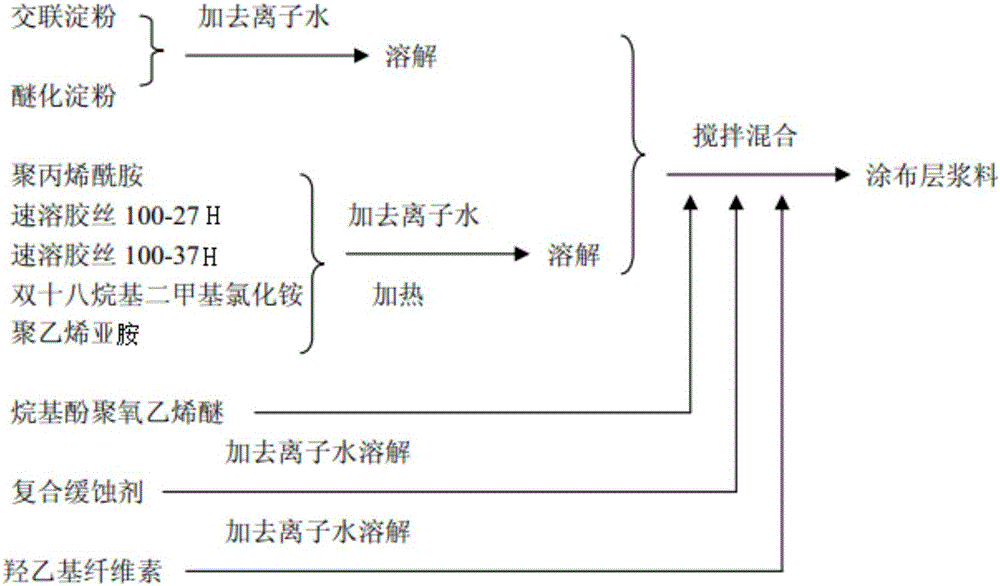

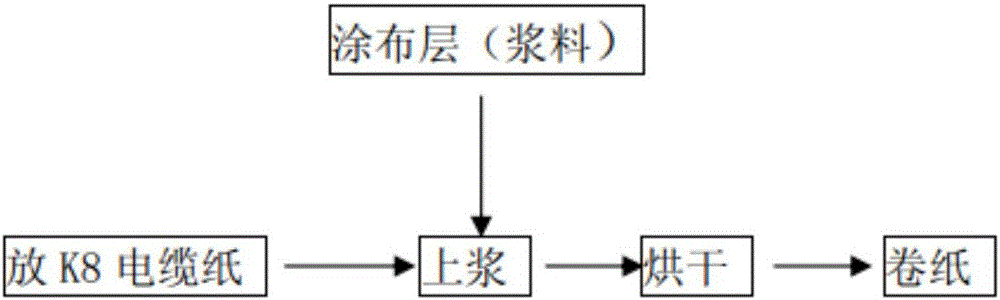

[0038] Add the modified starch in the above formula to deionized water to make a modified starch solution; then heat polyacrylamide, instant glue, dioctade...

Embodiment 2

[0040] This embodiment adopts K8 cable paper to produce pulp paper for high-speed battery production line (≥800 pieces / min). When preparing the layer, weigh each component according to the following formula:

[0041]

[0042] The instant glue in the above formula is composed of instant glue silk 100-27H and instant glue silk 100-37H produced by Hunan Xiangwei Co., Ltd. with a mass ratio of 18:16; the modified starch is produced by Foshan Huahao Huafeng Starch Co., Ltd. The mass ratio of cross-linked starch JLS and etherified starch H315 is 30:20; the composite corrosion inhibitor is composed of bismuth trichloride and EDTA, and the weight ratio of bismuth trichloride and EDTA is 4:1.

[0043] Add the modified starch in the above formula to deionized water to make a modified starch solution; then heat polyacrylamide, instant glue, dioctadecyldimethylammonium chloride and polyethyleneimine with deionized water Dissolve it, then add it to the prepared modified starch solution...

Embodiment 3

[0045] This embodiment adopts K8 cable paper to produce pulp paper for high-speed battery production line (≥800 pieces / min). When preparing the layer, weigh each component according to the following formula, and the sum of the weight percentages of each component of the following formula is 100%:

[0046]

[0047] The instant glue in the above formula is composed of instant glue silk 100-27H and instant glue silk 100-37H produced by Hunan Xiangwei Co., Ltd. with a mass ratio of 16:16; the modified starch is produced by Foshan Huahao Huafeng Starch Co., Ltd. Composition of cross-linked starch JLS and etherified starch H315 with a mass ratio of 25:25; the composite corrosion inhibitor is composed of bismuth trichloride and EDTA, and the weight ratio of bismuth trichloride and EDTA is 3:1.

[0048] Add the modified starch in the above formula to deionized water to make a modified starch solution; then heat polyacrylamide, instant glue, dioctadecyldimethylammonium chloride and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com