Floating breakwater

A floating breakwater and floating tank technology, applied in the field of marine engineering equipment, can solve the problems of reduced wave-absorbing capacity, complex structure, and limited breakwater width, and achieve the effects of easy disassembly and replacement, enhanced wave-absorbing performance, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

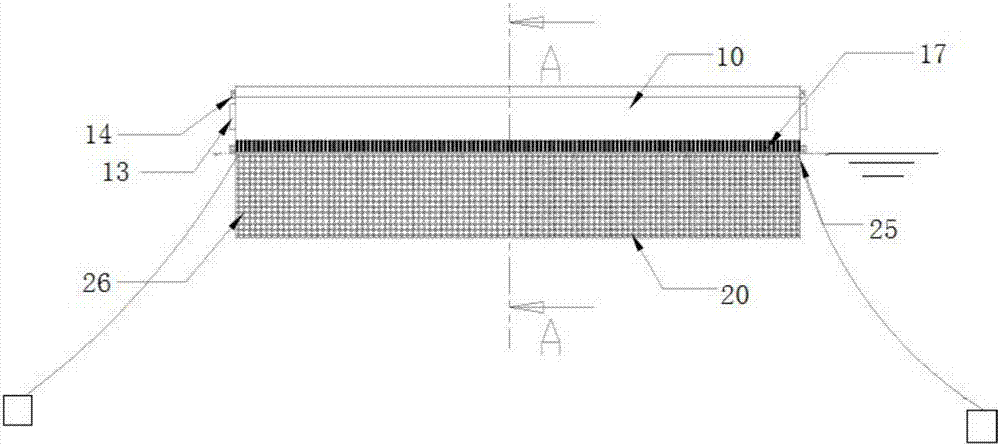

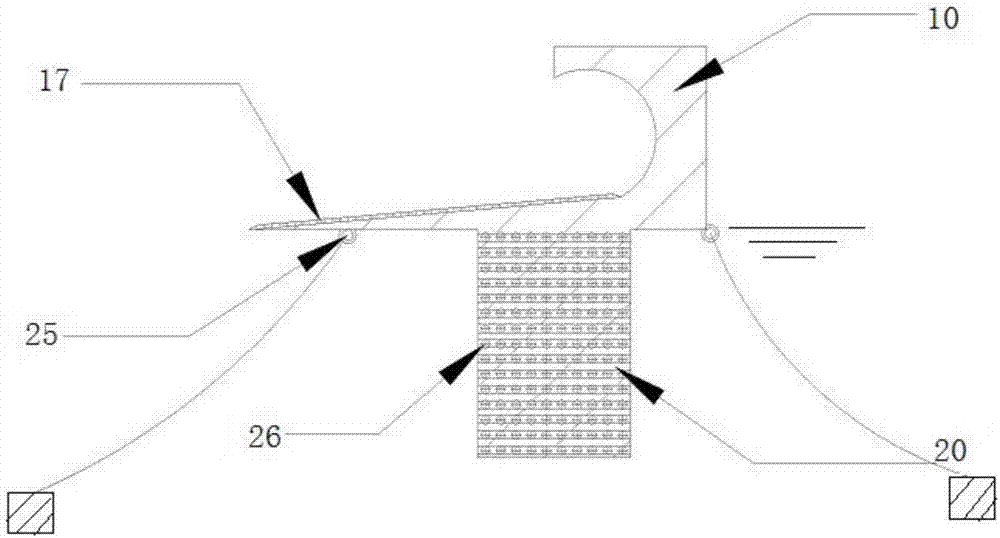

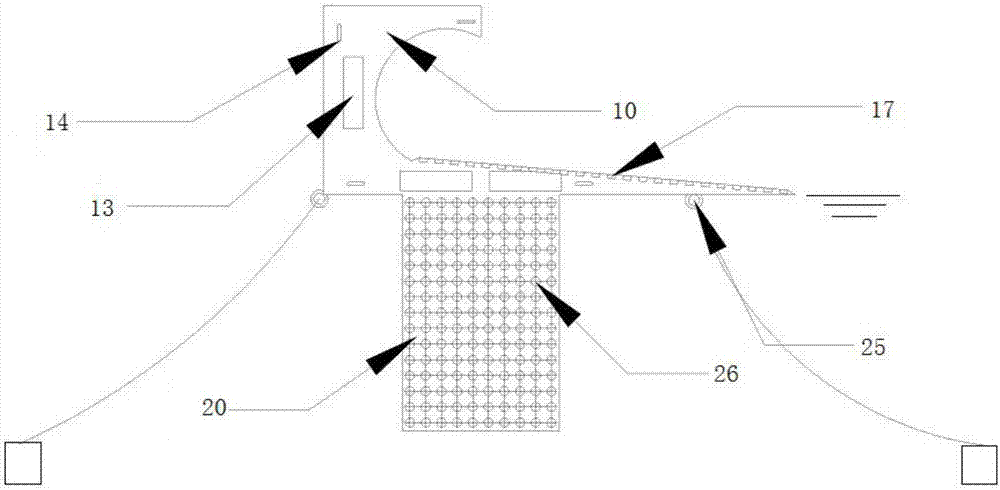

[0023] figure 1 It is a structural schematic diagram of the floating tank of an embodiment of the floating breakwater of the present invention. The invention consists of figure 1 The shown buoyant tank units are connected by connecting devices and then moored in the working sea area to form floating breakwaters. The length of the floating breakwater is determined by the number of pontoon units, which is theoretically unlimited.

[0024] The buoy box includes: an upper floating body 10, a lower floating body 20, a crash pad 13, a connecting fairlead 14, a mooring fairlead 25, a wave-dissipating hole 26, and a block energy dissipation device 17. The upper floating body 10 and the lower floating body 20 are consolidated into one body.

[0025] The upper floating body 10 of the buoyancy tank is made of steel material, and is a groove-shaped structure with a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com