Novel steel pipe pile bed rock drilling anchoring method

A technology for steel pipe piles and drilled anchors, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inability to meet anti-scouring requirements, insufficient driving depth of steel pipe piles, and increase cross-operation procedures, etc., to achieve The effect of fast construction speed, small size, and convenient entry and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

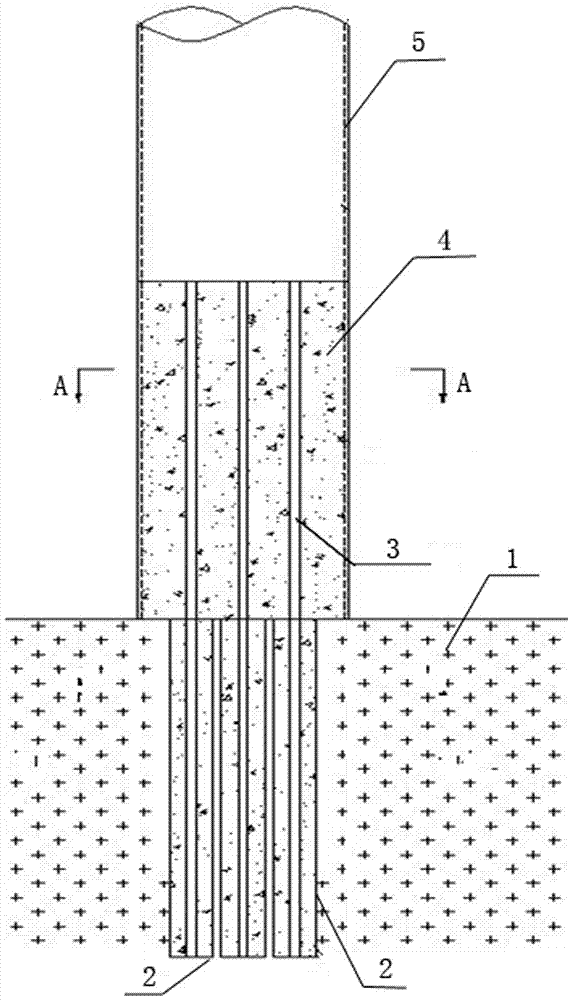

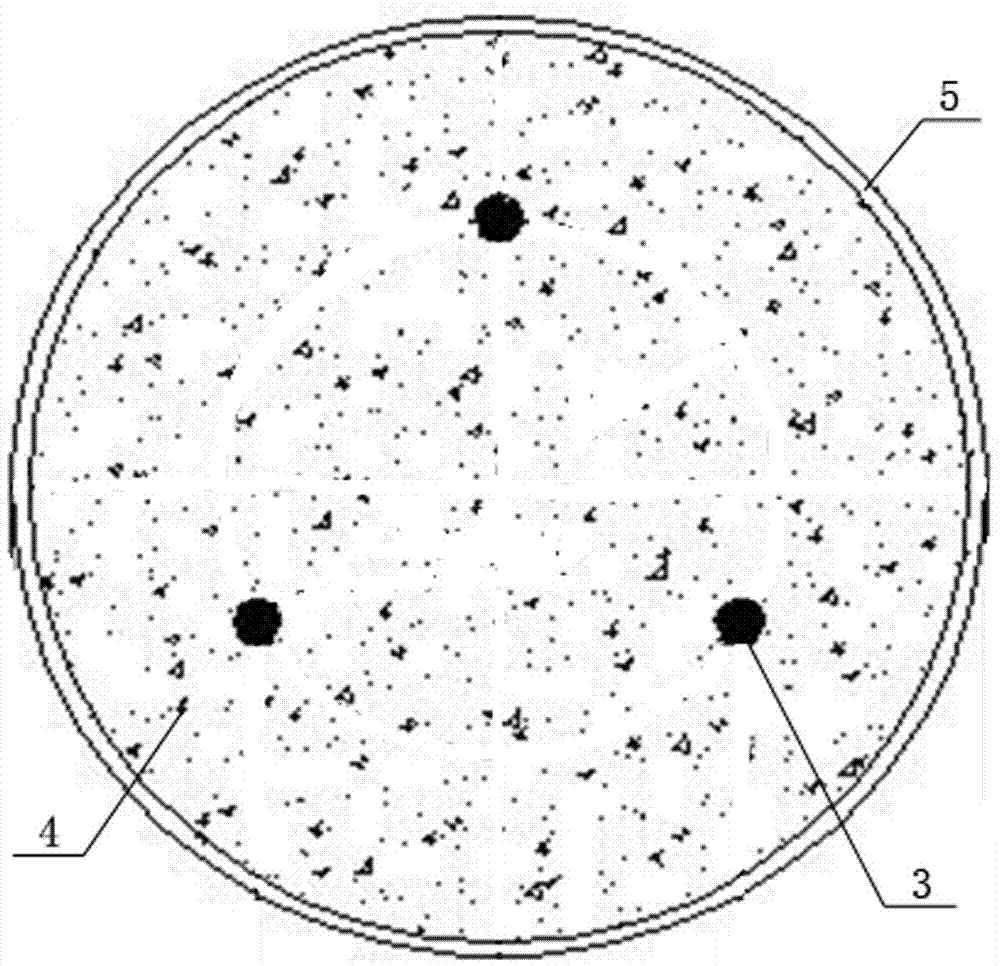

[0012] A novel steel pipe pile foundation rock drilling and anchoring method, comprising the following steps: first construct a trestle bridge or a platform near the thicker part of the river bed covering layer on the bank, lay the bridge deck, and form an operation platform; use the operation platform to lower the Φ630mm steel pipe, first The lowered Φ630mm steel pipe forms the working space. Use the construction casing to drill the anchor hole 2 on the bedrock 1 directly below the steel pipe. After drilling the anchor hole, lower the anchor bar 3 and consolidate it with grouting, and then backfill the broken pieces in the Φ630mm steel pipe. Stone or concrete 4 to form an anchoring body in which the anchoring steel bar and the steel pipe work together to achieve a stable effect.

[0013] Temporary structures such as trestles and platforms have met the bearing capacity requirements during construction, and other structures can continue to be erected while anchoring steel pipe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com