Heat gun

A hot air gun and hot air tube technology, applied in the field of hot air guns, can solve the problems of inconvenient operation, use, unreliable fixation, long moving stroke, etc., and achieve the effects of improving the safety of use, facilitating accurate operation, and improving the indication function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

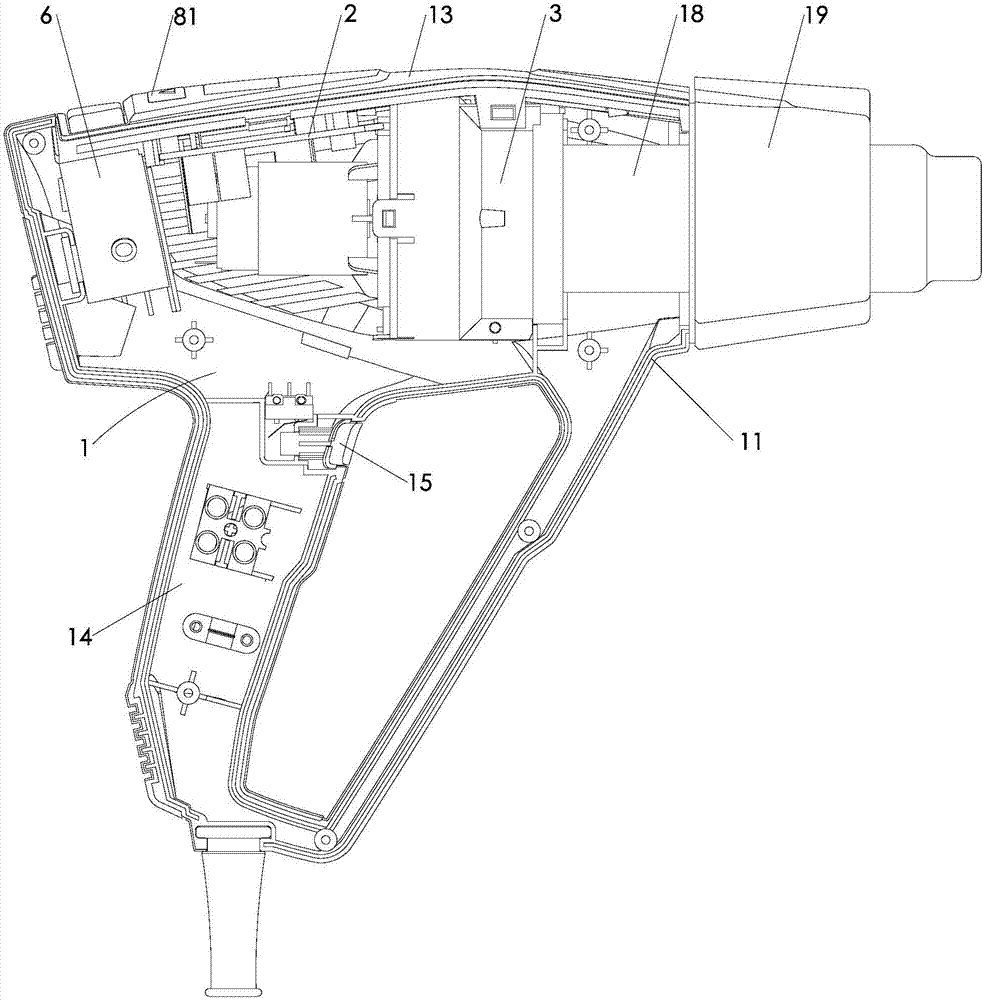

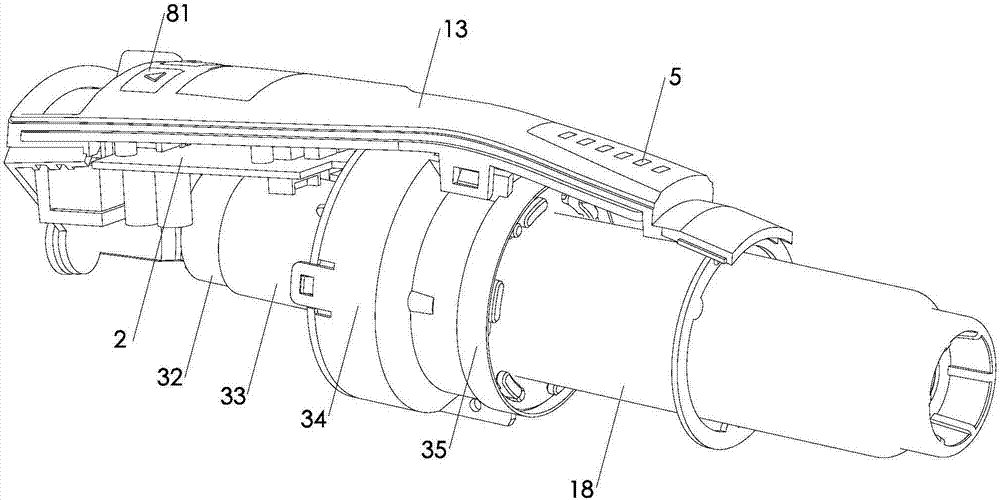

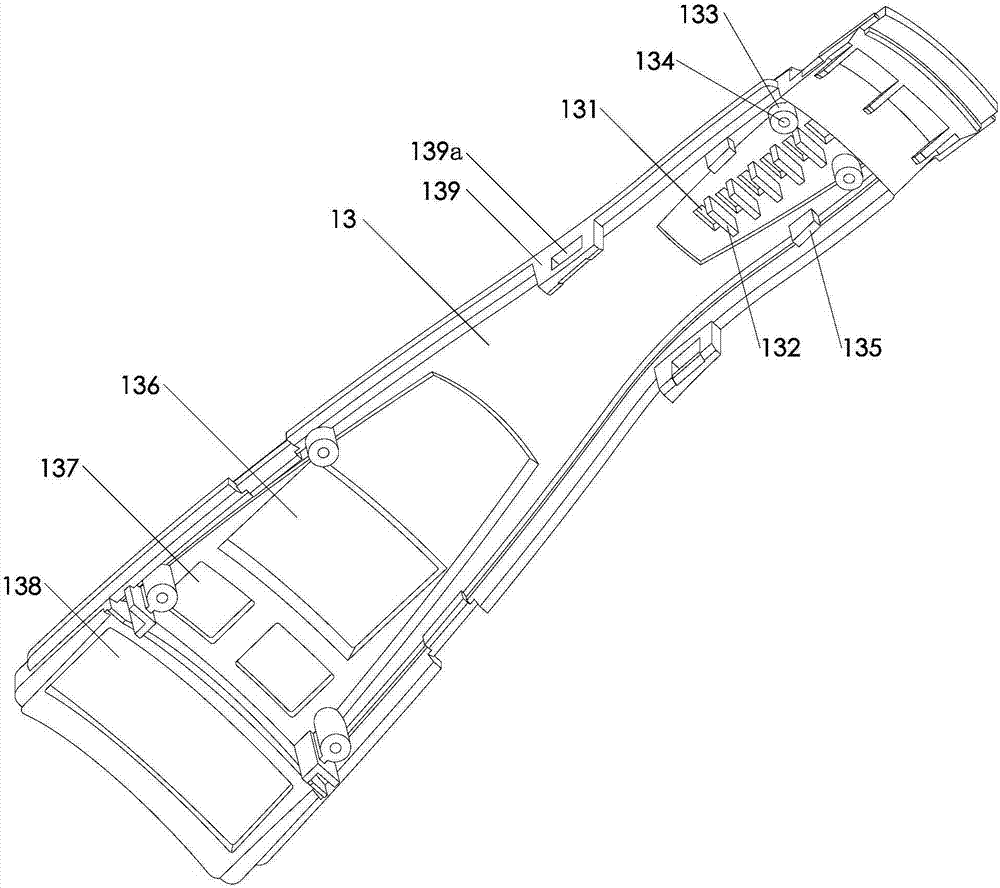

[0040] Such as Figure 1 to Figure 9 As shown, the heat gun provided by Embodiment 1 of the present invention includes a casing 1 , and a main control board 2 , a hot air device 3 , a temperature detection device 4 , a heating indicating device 5 and a knob 6 are arranged in the casing. Shell 1 comprises left shell 11, right shell 12 and top shell 13 that are fixed together, and the bottom of left shell and the bottom of right shell are all provided with integrally formed handle shell 14, and the handle shell of both sides Combined to form a handle, the handle is provided with a main switch 15 for switching on or cutting off the power supply, and the left housing and the right housing are provided with air inlets. The upper part of the left housing, the upper part of the right housing and the top housing are combined to form a housing chamber, the main control board 2, the hot air device 3, the temperature detection device 4, the heating indicating device 5 and the knob 6 are ...

Embodiment 2

[0072] The difference between the second embodiment of the present invention and the first embodiment above is that the main control board 2 is further provided with capacitors. After the hot air blower cuts off the power supply, the capacitor can supply power for a short time to the main control board 2 and the heating indicating device 5 . When the hot air blower is powered off, the residual temperature of the heating component 36 is high. When the residual temperature of the heating component exceeds a certain range, the command indicator light 52 of the main control board 2 will flash to remind the user to pay attention to avoid the user being burned by the residual temperature of the heating component. Or place the potential safety hazards of the hot air gun at will to improve the safety of use.

Embodiment 3

[0074] The difference between Embodiment 3 of the present invention and Embodiment 1 above is that the detection circuit board 41 is also provided with a laser head for positioning the detection position of the temperature detection device. The laser head can accurately locate and detect the specific position of the heated object, further ensuring the accuracy of the temperature detection device during detection, thereby better ensuring the heating effect of the heat gun on the heated object.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com