Soaking plate structure

A technology of vapor chamber and support structure, which is applied in indirect heat exchangers, lighting and heating equipment, etc., and can solve problems such as unfavorable steam diffusion, small steam channels, and unfavorable vapor chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

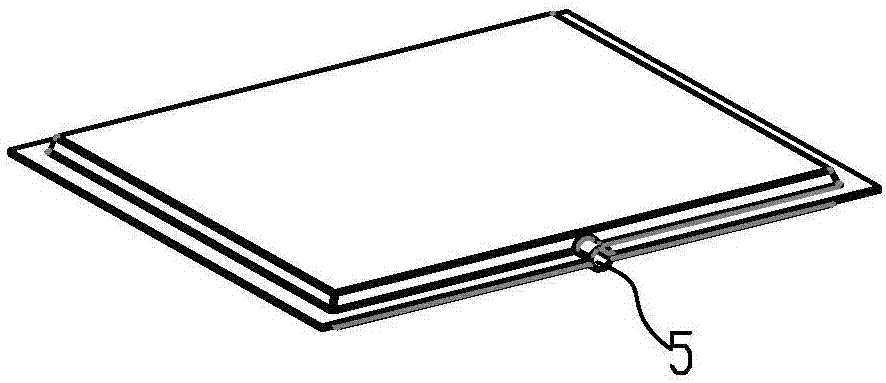

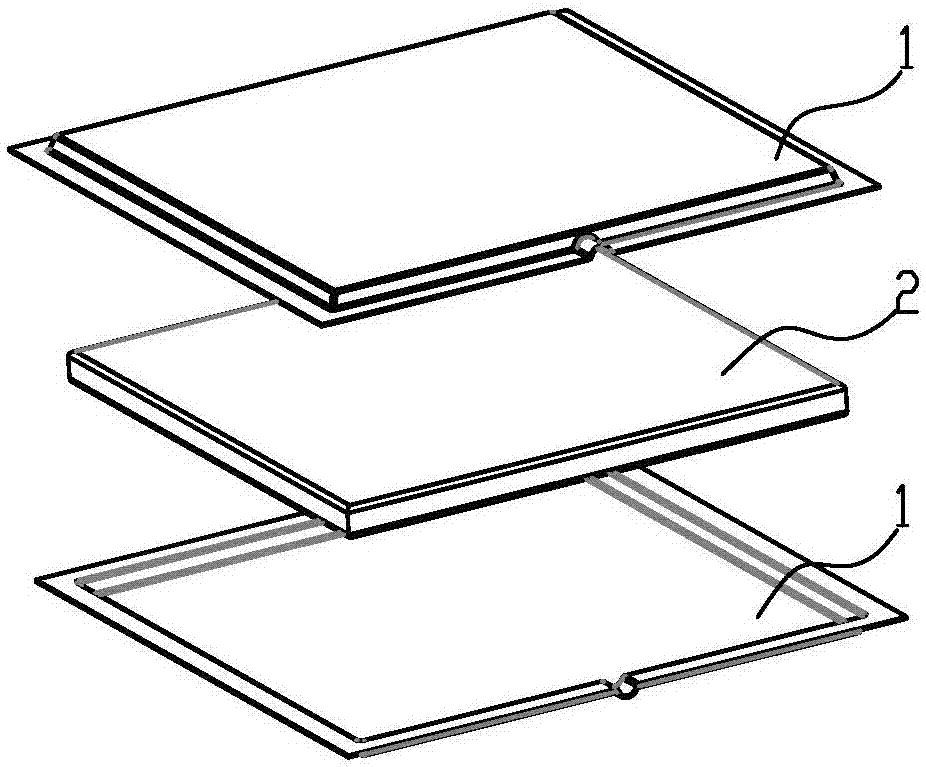

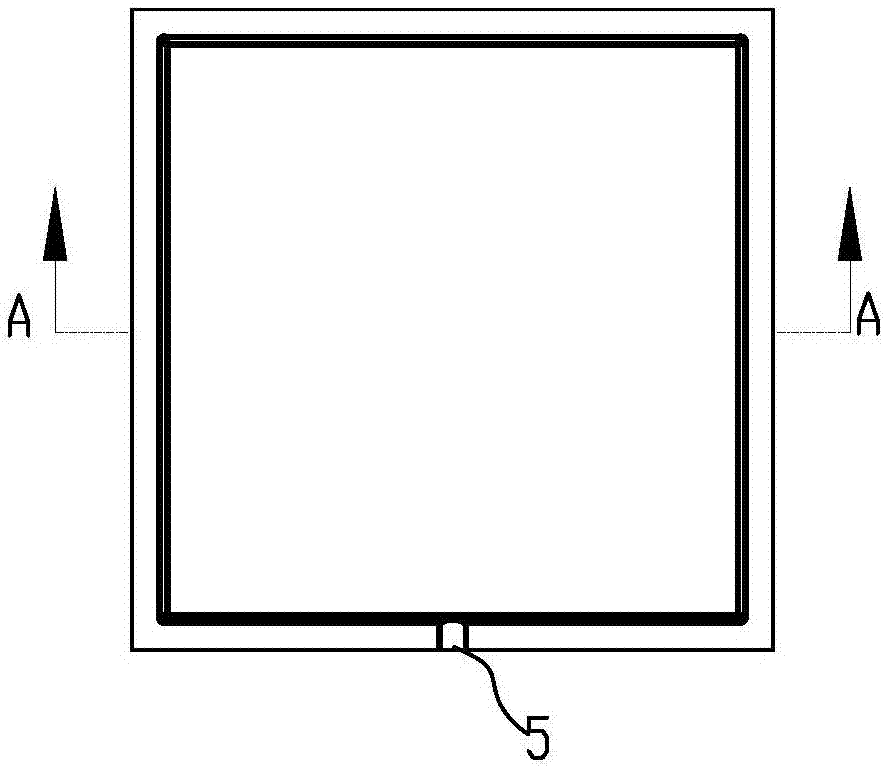

[0035] A vapor chamber structure, comprising an upper shell 1 and a lower shell 2 snapped together, a support structure is provided between the upper shell 1 and the lower shell 2, and the upper shell 1 and the lower shell 2 are covered To support the supporting structure, the lower surface of the upper shell plate 1 is affixed to the upper surface of the supporting structure, and the upper surface of the lower shell plate 2 is affixed to the lower surface of the supporting structure. The supporting structure includes such as Figure 11 As shown in the porous structure layer 3, the porous structure layer 3 is made of a porous material with a pore density of 5-30 ppi and a porosity of 80%-99%.

[0036] The support structure also includes several layers of capillary liquid-absorbing core layers 4 , and the several layers of capillary liquid-absorbing core layers 4 are fixedly connected to the porous structure layer 3 . The porous structure layer 3 is made of metal porous materia...

Embodiment 2

[0042] The main structure of this embodiment is the same as that of Embodiment 1, and the similarities will not be repeated here. The difference is that the structure of the vapor chamber in this embodiment is as follows Figure 5 , Figure 6 , Figure 7 shown. A capillary liquid-absorbing core layer 4 is arranged between the lower shell plate 2 and the porous structure layer 3, the upper surface of the porous structure layer 3 is fixedly connected to the groove surface of the upper shell plate 1, and the lower surface of the porous structure layer 3 is connected to the capillary suction core layer. The upper surface of the liquid core layer 4 is affixed, and the lower surface of the capillary liquid-absorbing core layer 4 is affixed to the groove surface of the lower shell plate 2, so as to play a supporting role. The surrounding edges of the upper shell plate 1 and the lower shell plate 2 are closely connected. Fit and connect, then inject working fluid through liquid inje...

Embodiment 3

[0044] The main structure of this embodiment is the same as that of Embodiment 1 or 2, and the similarities will not be repeated here. The difference is that the vapor chamber structure in this embodiment is as follows Figure 8 , Figure 9 , Figure 10shown. A capillary liquid-absorbing core layer 4 is arranged between the upper shell plate 1, the lower shell plate 2 and the porous structure layer 3, and the upper and lower surfaces of the porous structure layer 3 are respectively fixed with one side of the capillary liquid-absorbing core layer 4 located above and below it. The upper surface of the upper capillary liquid-absorbing core 4 is affixed to the groove surface of the upper shell plate 1, and the lower surface of the lower capillary liquid-absorbing core 4 is affixed to the groove surface of the lower shell plate 2, thereby playing a supporting role , the edges of the upper shell plate 1 and the lower shell plate 2 are tightly fitted and connected, and then the wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com