Flotation working condition classification method and system

A classification method and flotation technology, applied in character and pattern recognition, instruments, biological neural network models, etc., can solve problems such as difficulty in obtaining image information, underutilization of foam video, information loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

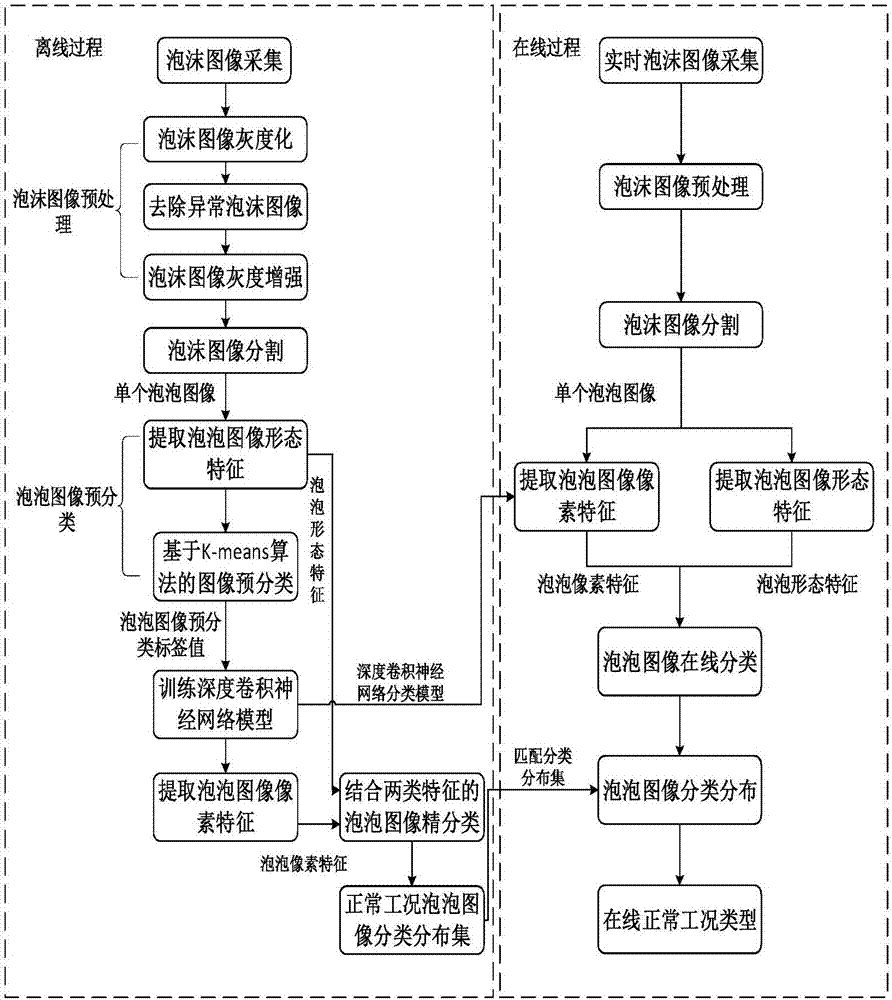

[0089] see figure 1 , this embodiment discloses a method for classifying flotation working conditions, including:

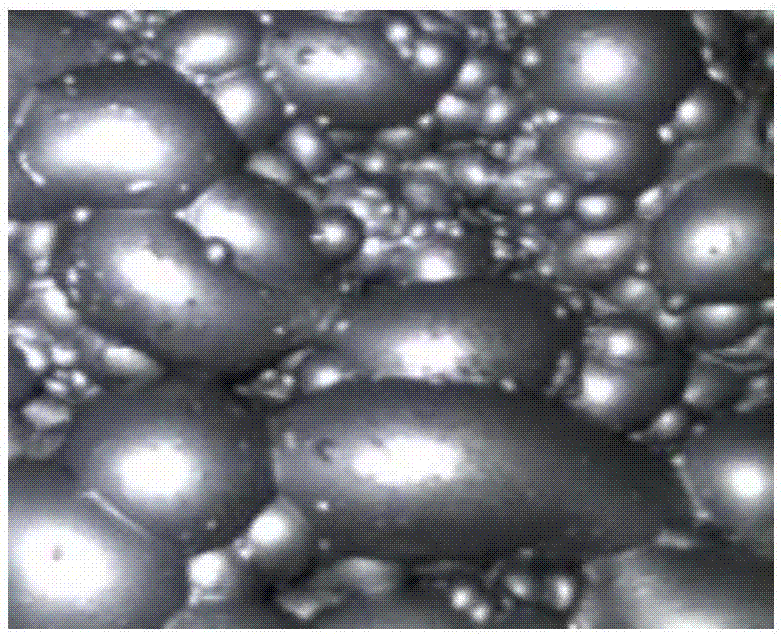

[0090] Obtain the flotation foam image and perform image preprocessing to obtain a foam image set suitable for building a model;

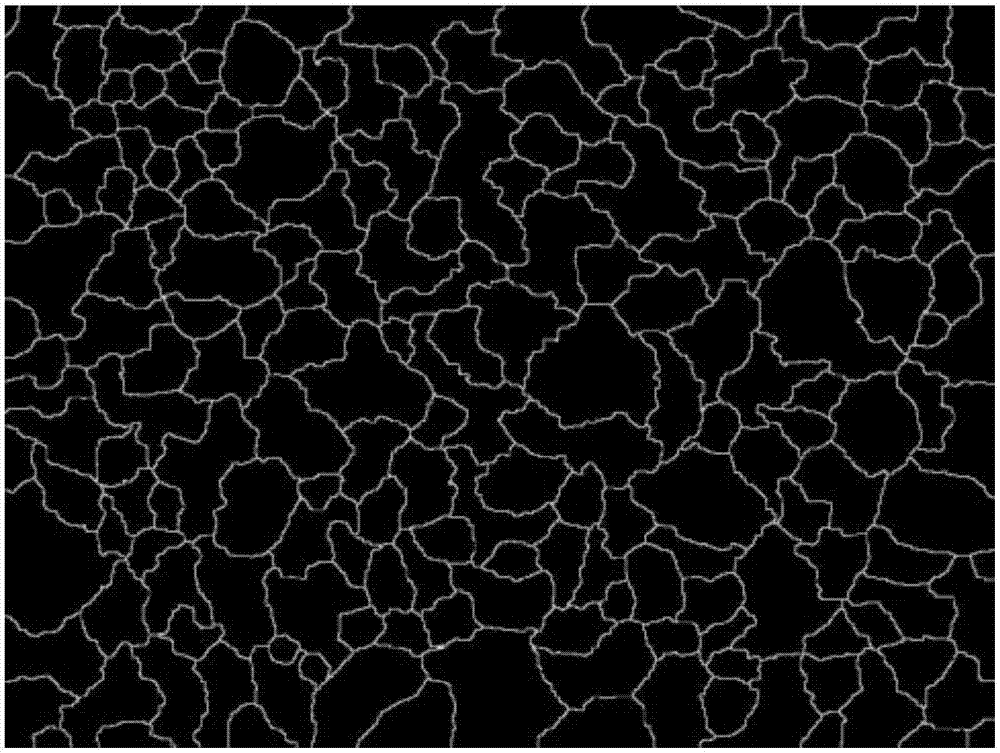

[0091] A two-step watershed algorithm is used for image segmentation for each single-frame foam image in the foam image set, and each bubble region is saved as a bubble image to obtain a bubble image set of all single-frame foam images in the foam image set;

[0092] Extract the morphological feature vector of the bubble image, and pre-classify the bubble image set according to the morphological feature vector, and obtain the classification label value of the bubble image; The convolutional neural network extracts the pixel set features of the bubble image, and trains a deep convolutional neural network model through a large number of existing bubble image data sets;

[0093] Extract the pixel set features of each bubble image accor...

Embodiment 2

[0167] A system for implementing the above-mentioned method for classifying flotation conditions, characterized in that it includes:

[0168] The first unit: used to obtain the flotation foam image, and perform image preprocessing to obtain a foam image set suitable for building a model;

[0169] The second unit: it is used to segment each single-frame foam image in the foam image set using a two-step watershed algorithm, and each bubble area is saved as a bubble image to obtain all single-frame foam images in the foam image set bubble image set;

[0170]The third unit: used to extract the morphological feature vector of the bubble image, and pre-classify the bubble image according to the morphological feature vector, and obtain the classification label value of the bubble image; use a deep convolutional neural network to extract the bubble The pixel set features of the image, combined with a large number of existing bubble image data sets corresponding to the classification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com