Automatic thickness-measuring and weighing equipment and automatic rubber coating machine and method for hexahedral parts

A glue wrapping machine and thickness measurement technology, which is applied in the direction of conveyor objects, battery assembly machines, transportation and packaging, etc., can solve problems such as potential safety hazards, impact of battery stacking, battery damage, etc., to achieve a strong degree of automation and improve handling Tempo, good for post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

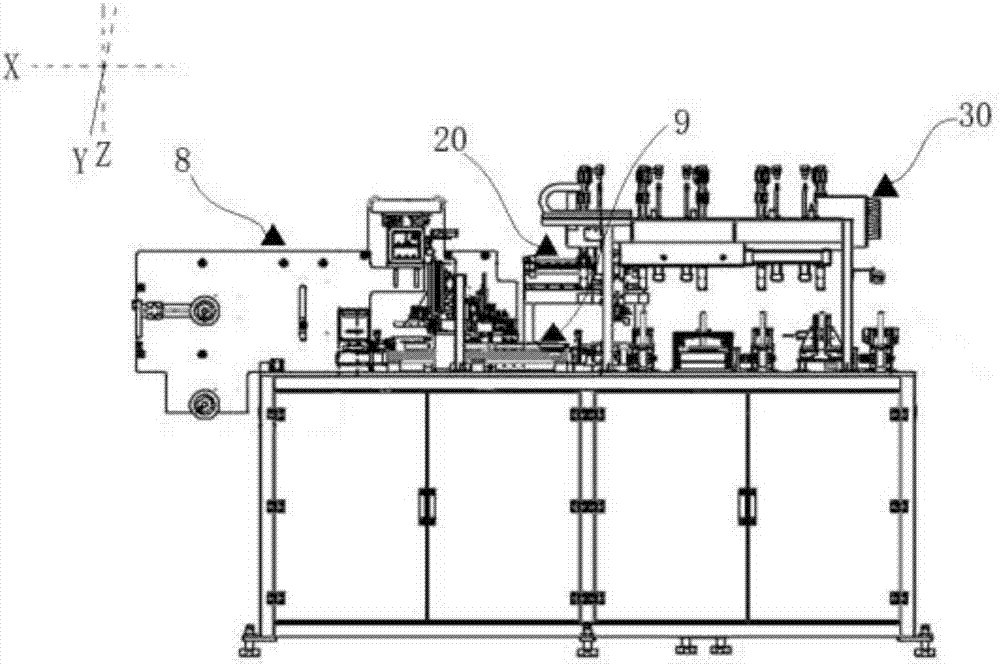

[0063] The invention discloses a six-sided parts automatic encapsulation machine, as attached figure 1 As shown, it includes an automatic thickness measuring and weighing device 30 , a feeding mechanism 20 , a film feeding mechanism 8 and an encapsulating mechanism 9 .

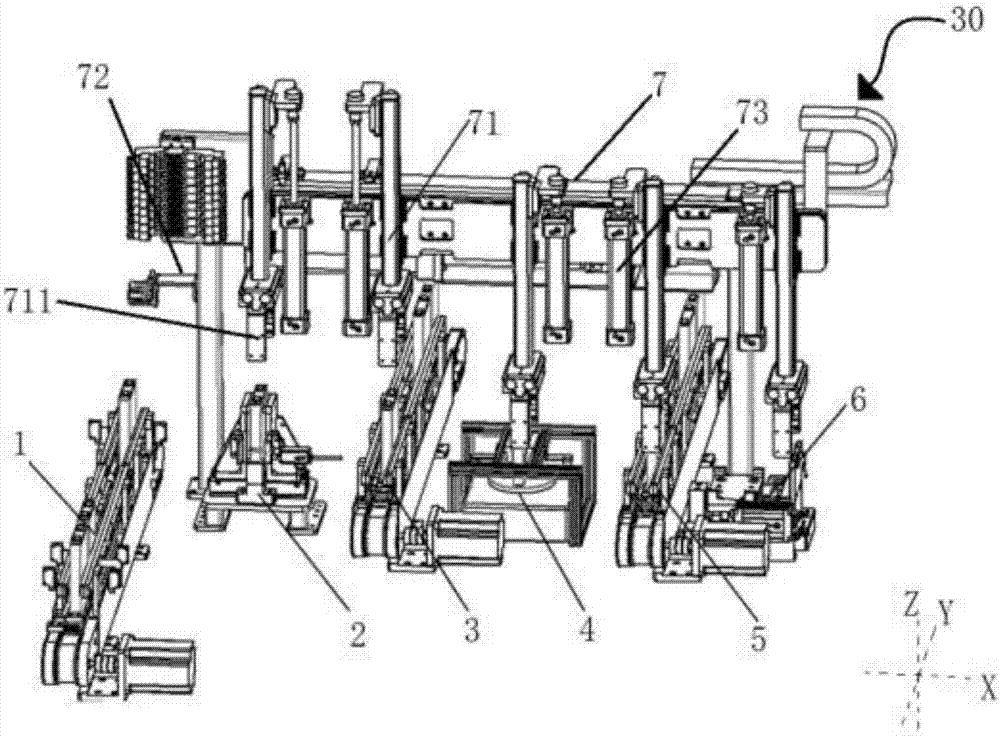

[0064] Among them, as attached figure 2 As shown, the automatic thickness measuring and weighing equipment includes six stations arranged in successive intervals, that is, the feeding conveyor line 1, the thickness measuring platform 2 for measuring the thickness of the workpiece, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap