Novel anti-blocking feed barrel

A technology of anti-blocking and feeding barrel, which is applied in the field of livestock breeding, can solve the problems of large resistance, difficulty in pushing the stirring blade for live pigs, and inability to feed powdered feed, so as to avoid mutual running around and facilitate the effect of impact management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

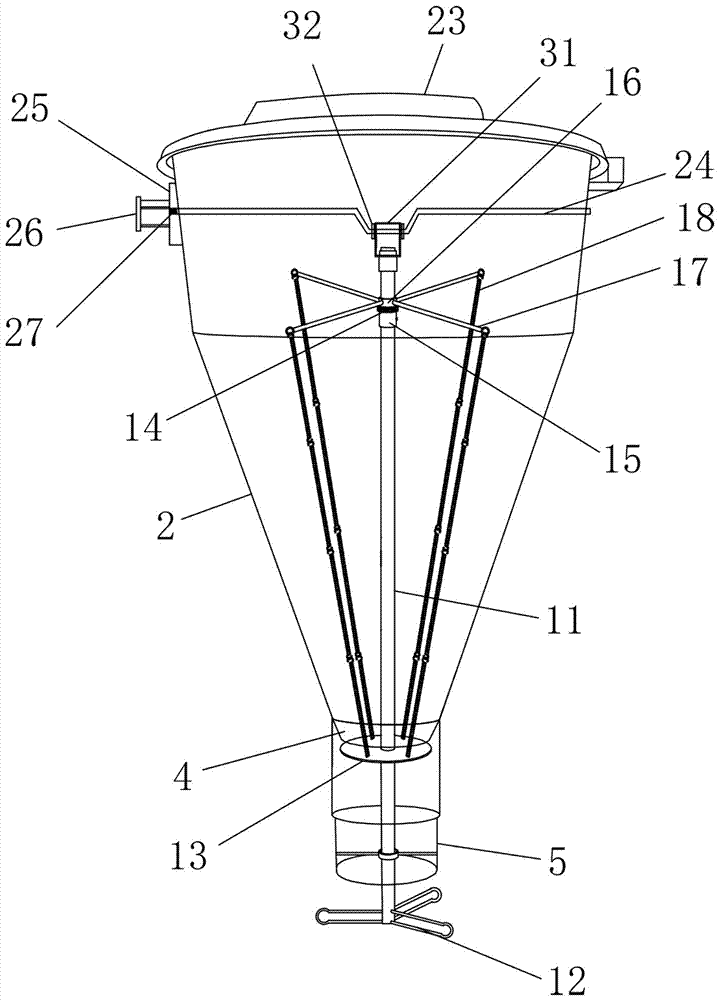

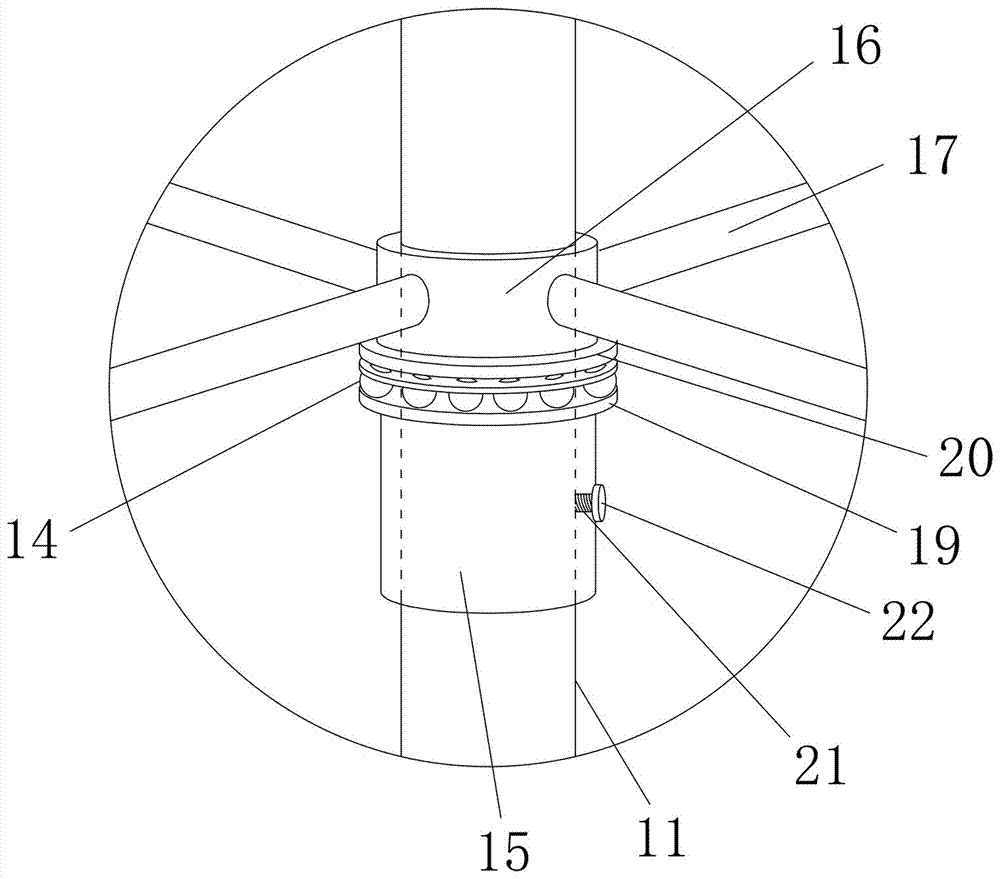

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

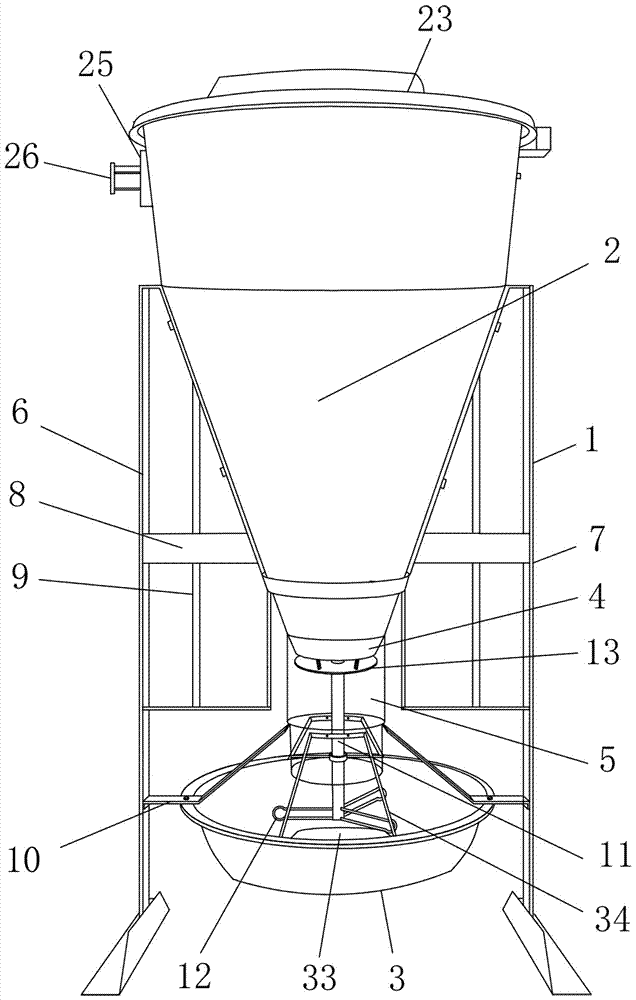

[0031] Such as figure 1 As shown, a novel anti-blocking barrel includes a bracket 1, a barrel body 2, and a trough 3. The barrel body 2 is vertically fixed on the bracket 1, and the top of the barrel body 2 is provided with a feed inlet 23, and the barrel body The bottom of 2 is provided with a discharge port 4, and a cylindrical protective cover 5 is set on the discharge port 4. The protective cover 5 is made of transparent material. Mouth 4 is opposite.

[0032] The bracket 1 includes a left support frame 6 and a right support frame 7 symmetrically arranged on both sides of the barrel body 2, and the left support frame 6 and the right support frame 7 include cross bars 8 and longitudinal bars 9 arranged perpendicularly to each other; Connecting rod 10 is arranged, and described trough 3 is fixed on the lower part of support 1 by connecting rod 10; The fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com