Engine and cam shaft, cam device and control cam of engine

A technology for controlling cams and cam devices, applied to engines and their camshafts, cam devices, and control cams. field, it can solve the problems of complex groove structure, limited axial movement space of the sleeve, cumbersome processing, etc., and achieve the effect of reducing the difficulty of layout, simple structure and shape, and simplifying the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

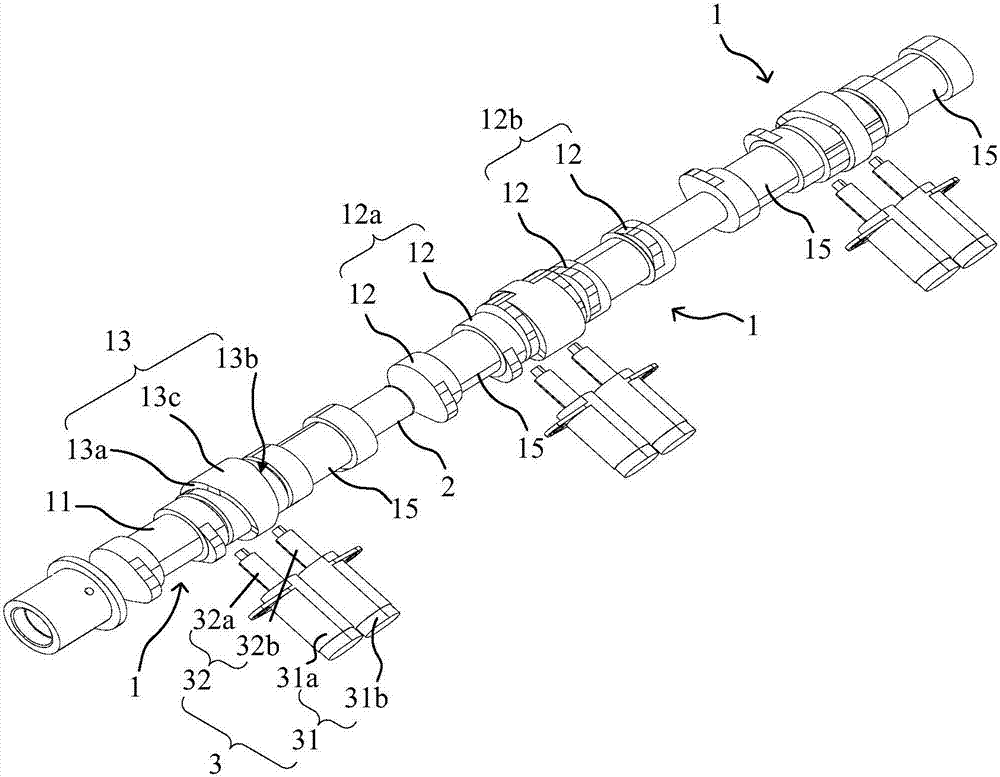

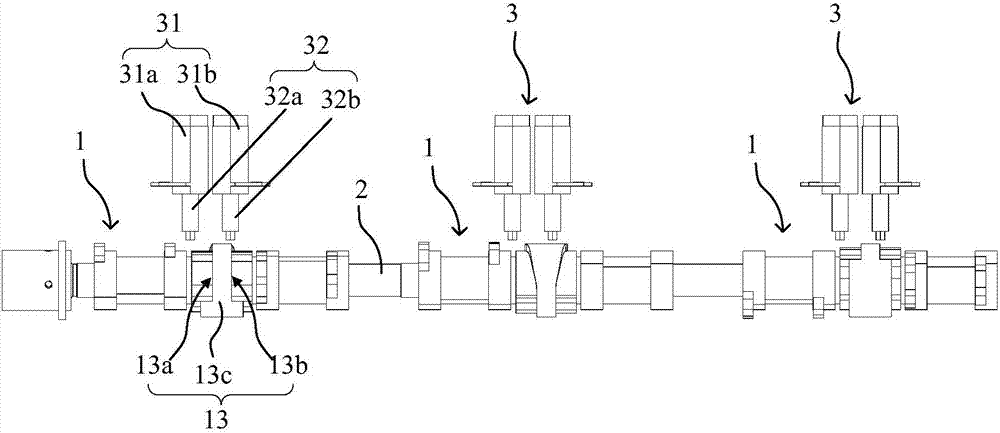

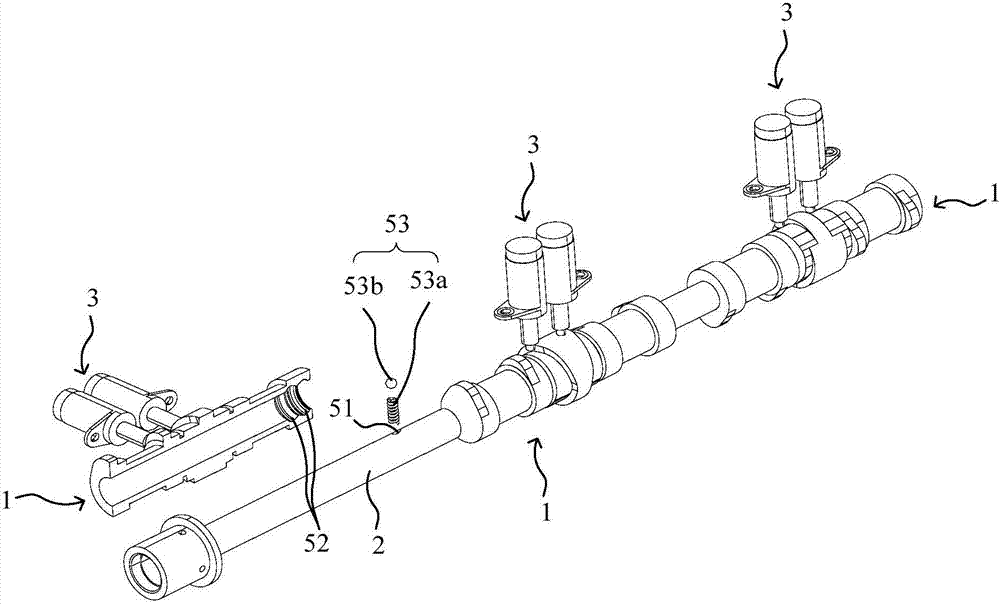

[0043] refer to Figure 1 to Figure 4 As shown, the embodiment of the present invention provides an engine and its camshaft, a cam device 1 and a control cam 13, wherein the control cam 13 is used in the cam device 1 of the engine camshaft. The cam device 1 is used to be sleeved on the mandrel 2, and forms an engine camshaft together with the mandrel 2. The cam device 1 and the mandrel 2 can be connected by splines or other structures, so that the cam device 1 can move along the axial direction of the mandrel 2 .

[0044] The actuator 3 is arranged outside the camshaft and fixed on the cylinder or the cylinder head as a driving part for driving the axial movement of the cam device 1. The actuator 3 can act on the control cam 13 when the cam device 1 needs to move, thereby The cam device 1 is pushed to move in the axial direction of the mandrel 2 .

[0045] In addition to the control cam 13, the cam device 1 also includes a sleeve 11 and a pair of cams 12 arranged on the slee...

no. 2 example

[0080] Such as Figures 11 to 13 As shown, the difference between this embodiment and the first embodiment is that the structure of the control cam is different. In the control cam 13 of this embodiment, the design of the first driving surface 13a and the second driving surface 13b is the same as that of the first embodiment ,Such as Figure 13 , the first driving surface 13a and the second driving surface 13b respectively include an entry section p1, a switching section p2 and an exit section p3 sequentially connected along the circumferential direction of the control cam 13, and the cam device 1 is activated when the switching section p2 cooperates with the actuator 3 drive. In other words, when the actuator 3 is in contact with the entry section p1 or the exit section p3, it cannot push the cam device 1 to move in the axial direction.

[0081] Such as Figures 11 to 13 As shown, the difference between the control cam of this embodiment and the control cam of the first em...

no. 3 example

[0088] This embodiment provides another engine, which differs from the engine of the first embodiment in that the cooperation relationship between the actuator 3 and the control cam 13 is different.

[0089] In this embodiment, the locking pins (i.e. the first locking pin 32a and the second locking pin 32b) of the locking pin portion 32 are not fully stretched out when they are in contact with the end point of the entry segment p1, and are in the process of contacting the switching segment p2. fully extended.

[0090] That is to say, when the lock pin of the lock pin part 32 needs to be stretched out to cooperate with the corresponding driving surface, the lock pin stretches out and enters the entry section p1, and during the movement of the lock pin from the starting point to the end point of the entry section p1, The locking pin is in the process of constantly extending.

[0091] However, when the locking pin moves to the end of the entry section p1, the locking pin has not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com