Method of predicting remaining life of equipment based on improved unscented particle filtering

A particle filter and life prediction technology, which is applied in prediction, design optimization/simulation, special data processing applications, etc., can solve problems such as missing, and achieve the effect of reducing particle degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

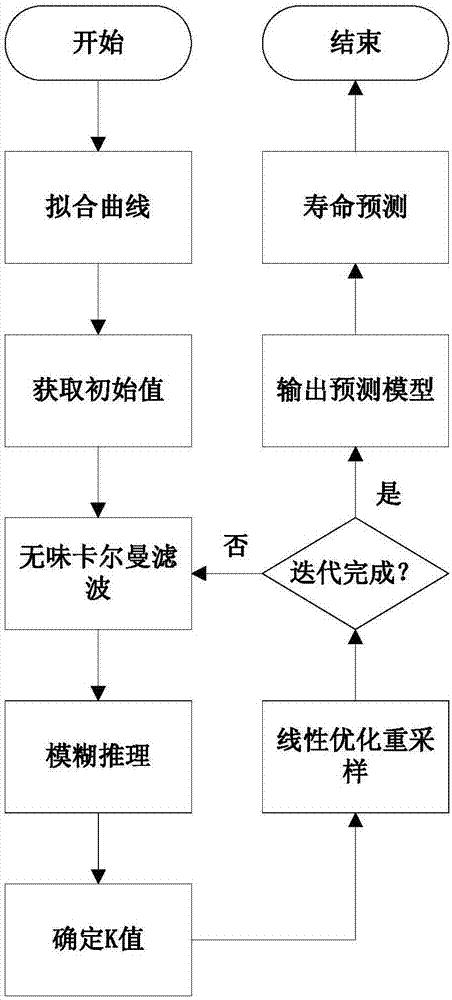

[0048] Embodiments Taking lithium-ion batteries as an example, a method for predicting the remaining life of equipment based on improved odorless particle filtering is provided, and the specific steps are as follows:

[0049] Step 1: Select training data, and perform curve fitting on the training data based on the degradation model.

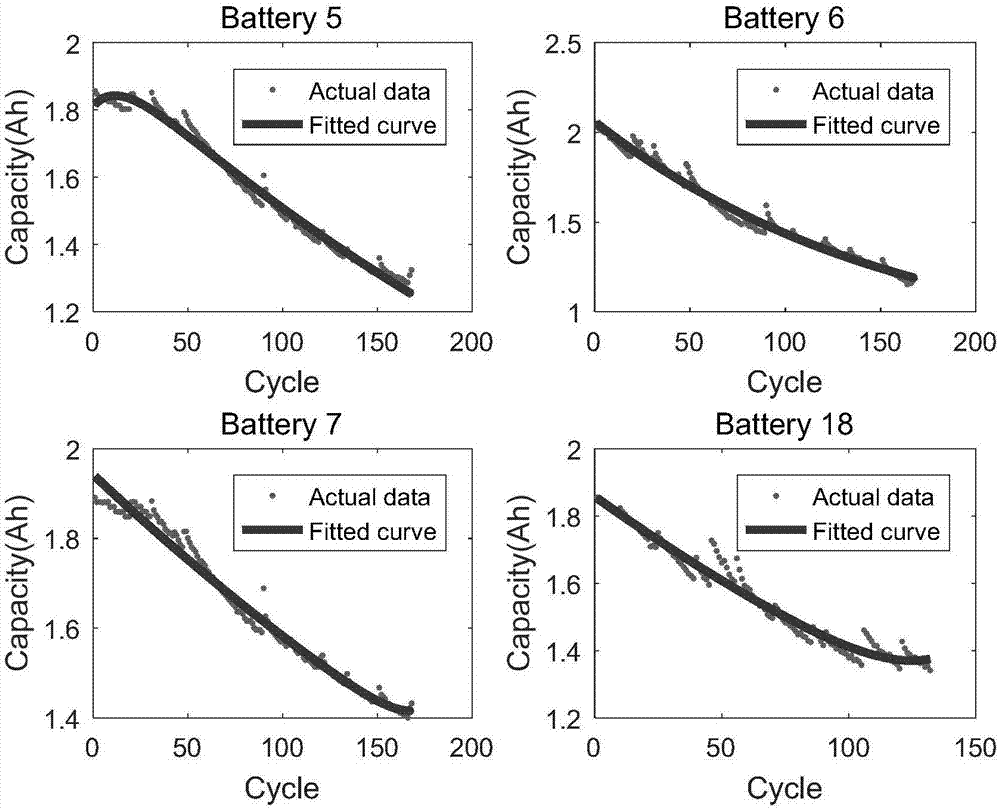

[0050] This step uses the empirical degradation model, and uses the BatteryData Set test data provided by NASA's Fault Prediction Center of Excellence as training data. In this example, the data of batteries No. 5, 6 and 7 are used as training data, and the data of No. 18 batteries are used For life prediction, use the matlab toolbox to perform curve fitting on the data of No. 5, No. 6, No. 7, and No. 18 batteries. The obtained results are as follows figure 2 As shown, the empirical degradation model is:

[0051] Q=a·exp(b·k)+c·exp(d·k)

[0052] Q is the lithium battery capacity; a, b, c, and d are model parameters; k is the number of cycles. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com