Herringbone double-driving foot linear ultrasonic motor

A linear ultrasonic motor, herringbone technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of complex structure, large volume, complex assembly and processing, etc. , to achieve the effect of large output displacement, small overall volume and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

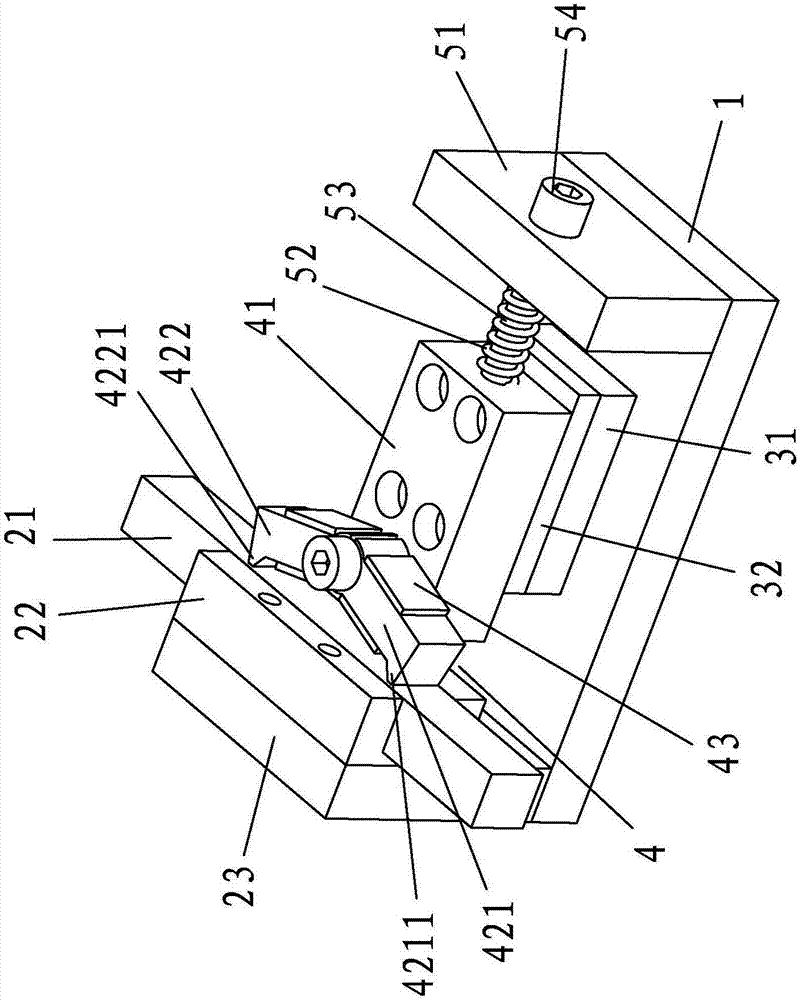

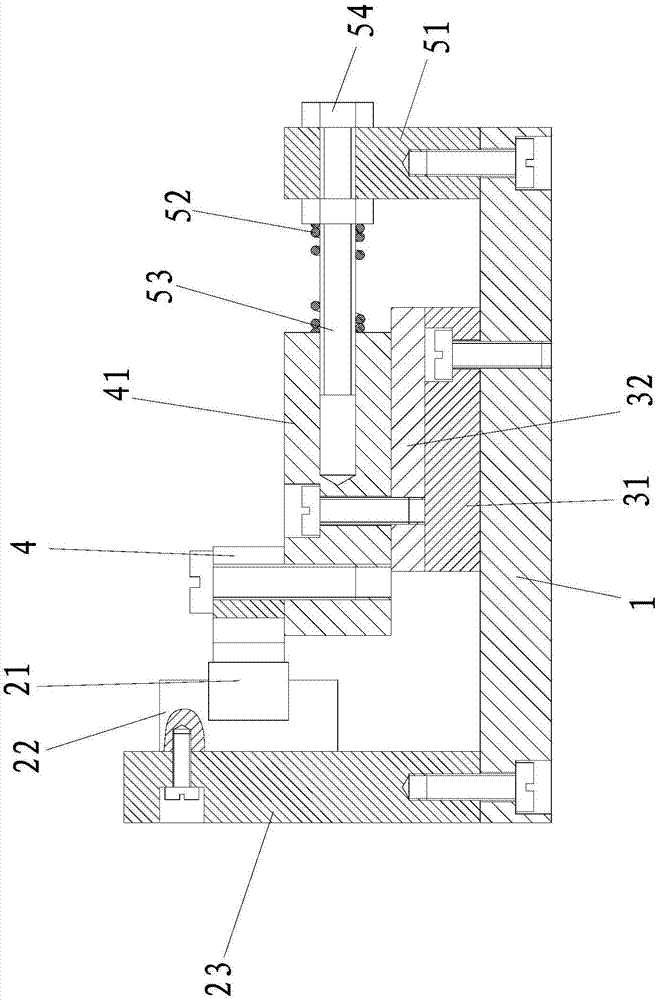

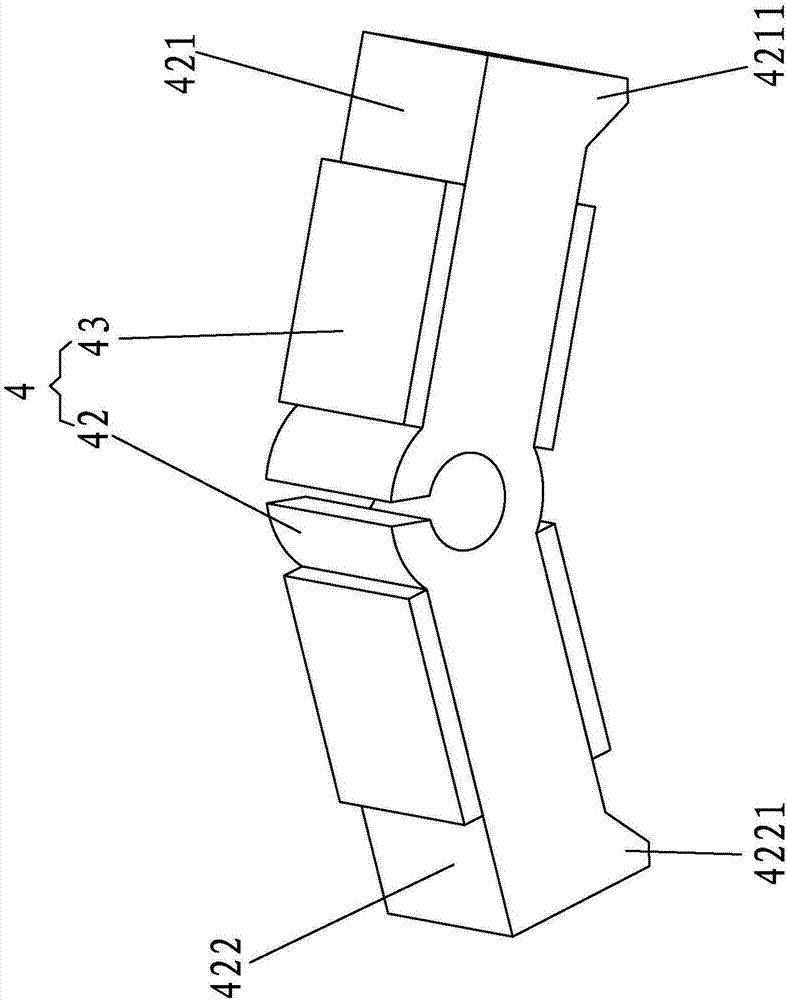

[0030] A linear ultrasonic motor driven by a herringbone biped, such as Figure 1-3 As shown, it includes a base 1, a mover 21, a stator 4 and a driving power supply. The mover 21 and the stator 4 are arranged side by side, and the drive power supply can output two independent drive signals.

[0031] For convenience of description, the figure 2 The orientation shown is the reference direction of the present invention.

[0032] The mover 21 is slidably installed on the base 1. Specifically, the left end of the base 1 is horizontally equipped with a mover guide rail 22, and the guide rail of the mover guide 22 faces the right end of the base 1. The mover 21 is installed It is in the mover guide rail 22 and can slide along the mover guide rail 22 . Preferably, the mover guide rail 22 is installed on the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com