Receiver and assembly technique thereof

An assembly process and receiver technology, which is applied in earphone manufacturing/assembly, loudspeakers, microphones, etc., can solve the problems of complex assembly process and complex structure of the receiver, and achieve the effect of simplifying the assembly process, simplifying the assembly process and improving the assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

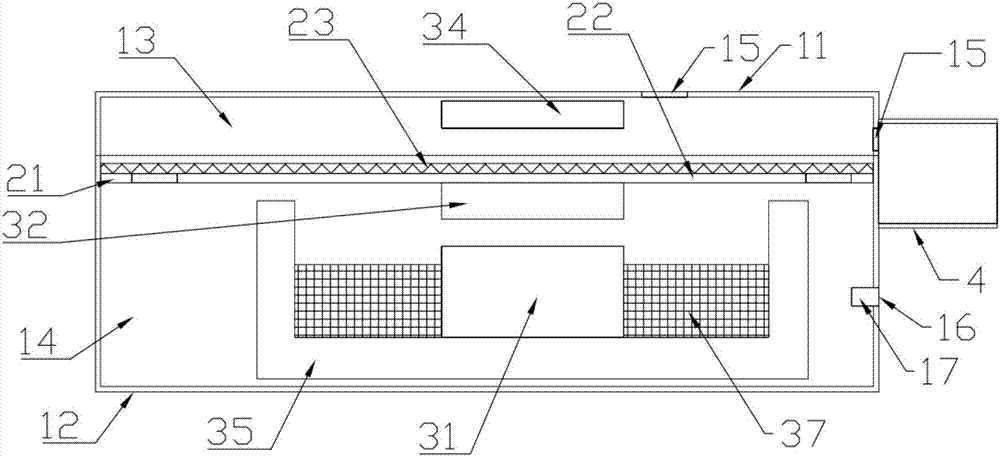

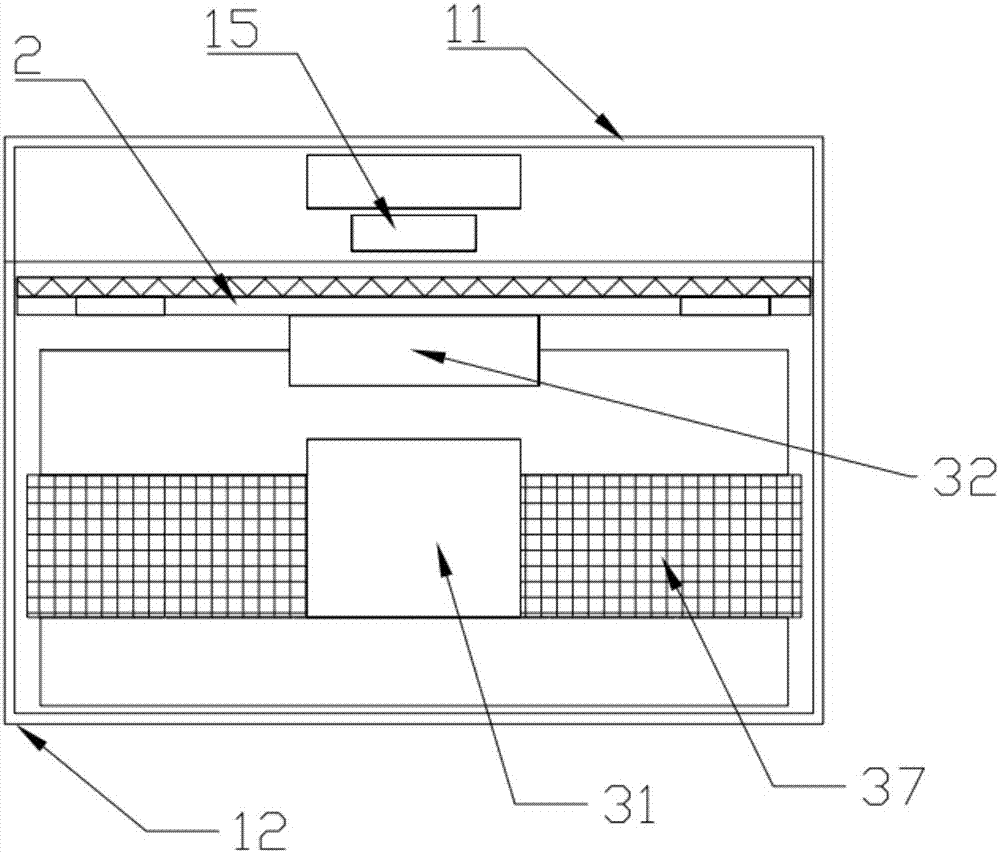

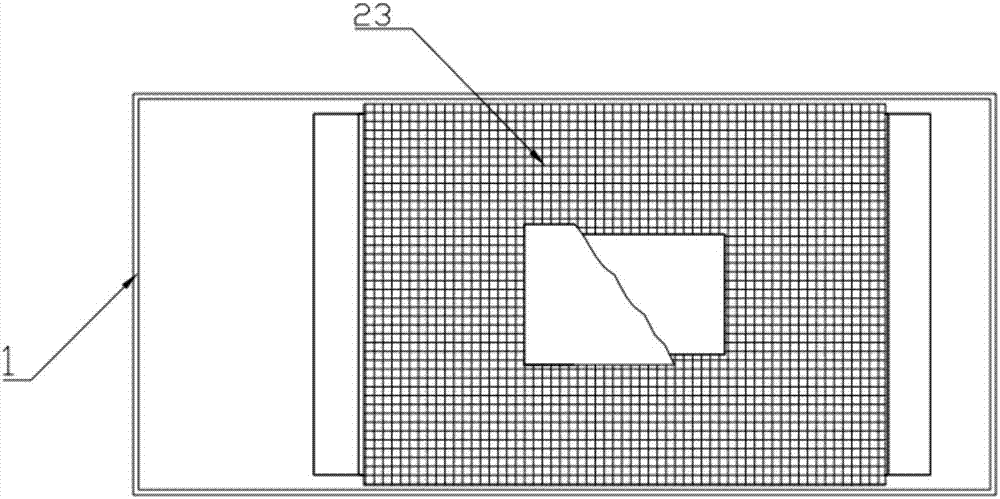

[0058] This embodiment provides a receiver, such as Figure 1 to Figure 3 As shown, it includes a casing 1 , a diaphragm mechanism 2 , an electromagnetic assembly and a soft magnet 32 .

[0059] Such as figure 1 As shown, the shell 1 includes a first shell 11 made of a first bottom surface and a side wall, and a second shell 12 made of a second bottom surface and a side wall; the second shell 12 is detachably connected to the first shell The body 11 is fastened to form an inner cavity. The diaphragm mechanism 2 is arranged between the openings of the first shell 11 and the second shell 12, and divides the inner cavity of the shell 1 into a first cavity 13 close to the first bottom surface and a second cavity close to the second bottom surface Body 14. That is, the inner cavity of the first housing 11 serves as the first cavity 13 , and the inner cavity of the second housing 12 serves as the second cavity 14 . Both the first housing 11 and the second housing 12 are prefer...

Embodiment 2

[0086] This embodiment provides a receiver, such as Figure 4 As shown, the difference between it and the receiver provided in Embodiment 1 is that the soft magnet 32 is replaced by the second permanent magnet 33, and the corresponding electromagnetic assembly includes a coil 37 arranged in the second cavity 14 and a coil embedded in the coil 37. The stem 36, other structures are the same as those of the receiver in Embodiment 1.

[0087] The receiver of this structure, if the polarity of the bottom one end of the second permanent magnet 33 is the S pole, the polarity of the top end is the N pole; Pass forward electricity to the coil 37, the coil 37 produces an electromagnetic field, and it is towards the second permanent magnet 33 The polarity of one end of the bottom is the S pole, according to the repulsion of the same sex, the second permanent magnet 33 is driven to drive the vibrating plate 22 to vibrate upward; The polarity of the bottom end of the second permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com