High Performance Nonwoven Structures

A technology of non-woven and non-woven materials, applied in the direction of bandages, other household utensils, layered products, etc., which can solve the problems of decreased absorbency and capacity, increased leakage, insufficient absorbency and capacity of the section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Example 1: Three-layer nonwoven acquisition material

[0137] This example provides a three-layer nonwoven acquisition material in accordance with the disclosed subject matter.

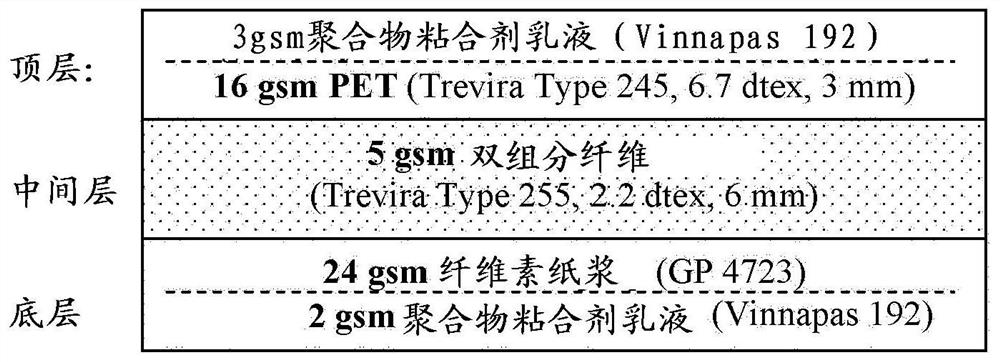

[0138] Using a pilot drum-former, a first material was formed. The top layer of the three-layer nonwoven acquisition material consisted of 16 gsm PET fibers (Trevira Type 245, 6.7 dtex, 3 mm) bonded with a polymer binder in emulsion form (Vinnapas 192, Wacker) at 3 gsm. The middle layer consisted of 5gsm bicomponent fibers (Trevira 1661, Type 255, 2.2dtex, 6mm). The bottom layer consisted of 24 gsm cellulose (GP 4723, fully treated pulp from Georgia-Pacific) bonded with 2 gsm of polymer binder in emulsion form (Vinnapas 192, Wacker). The average thickness of the fabricated structures was 0.76 mm. figure 1 A schematic illustration of the composition of the first material is given. Three samples of the same material were prepared.

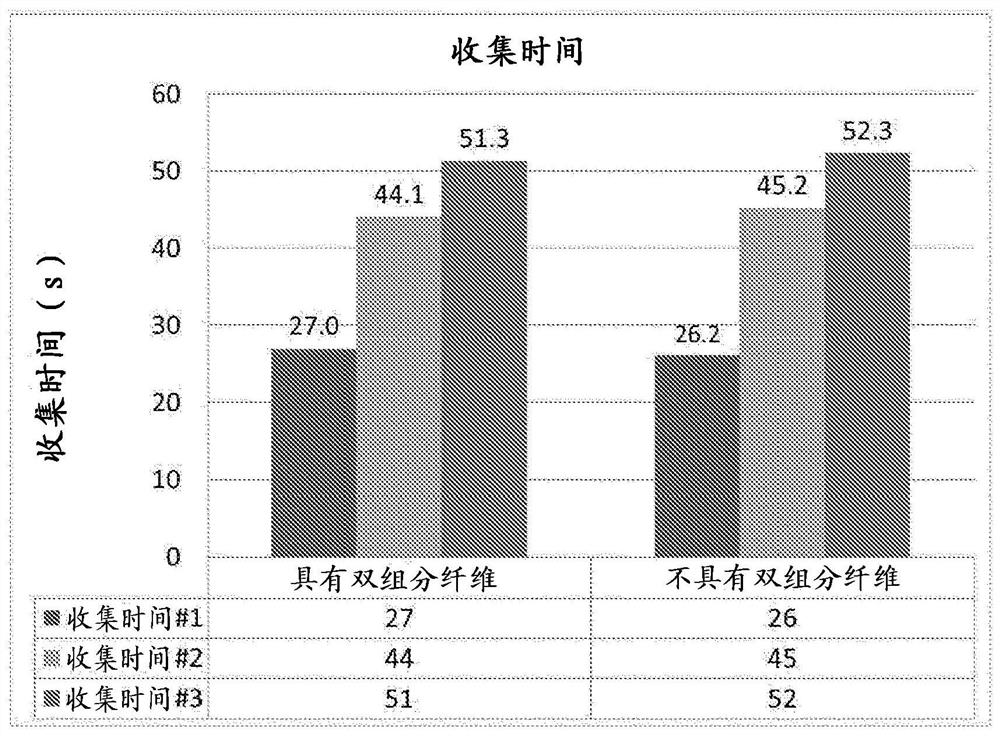

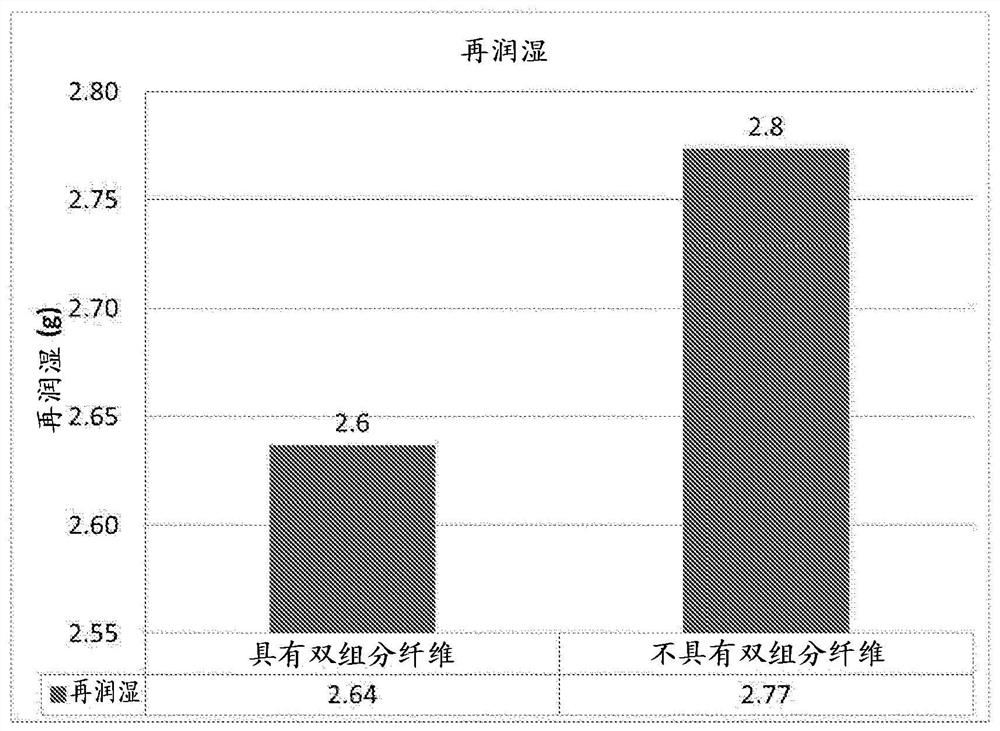

[0139]A second material was produced having the same struct...

Embodiment 2

[0150] Example 2: Three-layer nonwoven acquisition material

[0151] This embodiment provides a three-layer nonwoven acquisition material according to the disclosed subject matter.

[0152] Using a laboratory pad former, form the material. The top layer of the three-layer nonwoven acquisition material consisted of 16 gsm PET fibers (Trevira Type 245, 6.7 dtex, 3 mm) bonded with a 3 gsm polymer binder in emulsion form (Vinnapas 192, Wacker). The middle layer consisted of 5gsm bicomponent fibers (Trevira 1661, Type 255, 2.2dtex, 6mm). The bottom layer consisted of 24 gsm cellulose (GP 4725, semi-treated pulp) bonded with 2 gsm of polymer binder in emulsion form (Vinnapas 192, Wacker). The average thickness of this structure was 1.02 mm. Figure 4 A schematic illustration of the composition of the collected material is given. Three samples of the same material were prepared.

[0153] Using a synthetic blood solution, the fluid collection characteristics of the collection mat...

Embodiment 3

[0156] Example 3: Liquid Acquisition Nonwovens

[0157] For comparative purposes, the examples of the present invention provide two control liquid acquisition nonwoven materials. These materials are designated 3A and 3B. Three sets of each material were prepared. These controls are commercially available products: LBAL (latex-bonded airlaid) product (Vicell 6609, also known as 60MAR S II) and MBAL (multi-bonded airlaid) (Vizorb 3074 , also known as 60MBAL), both products are manufactured by Georgia-Pacific in Steinfurt, Germany. The two control products had a basis weight of 60 gsm.

[0158] The fluid acquisition characteristics of the control materials were measured with synthetic blood solutions using the fluid acquisition performance testing procedure described below. Synthetic blood was purchased from Johnson, Moen & Co. Inc. (Rochester, MN) (Lot #201141; February 2014). The synthetic blood has a surface tension of 40-44 dyne / cm (ASTM F23.40-F1670) and includes variou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com