Laser welding apparatus and laser welding method

A laser welding, laser technology, applied in laser welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of coloring, low transparency, opacity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

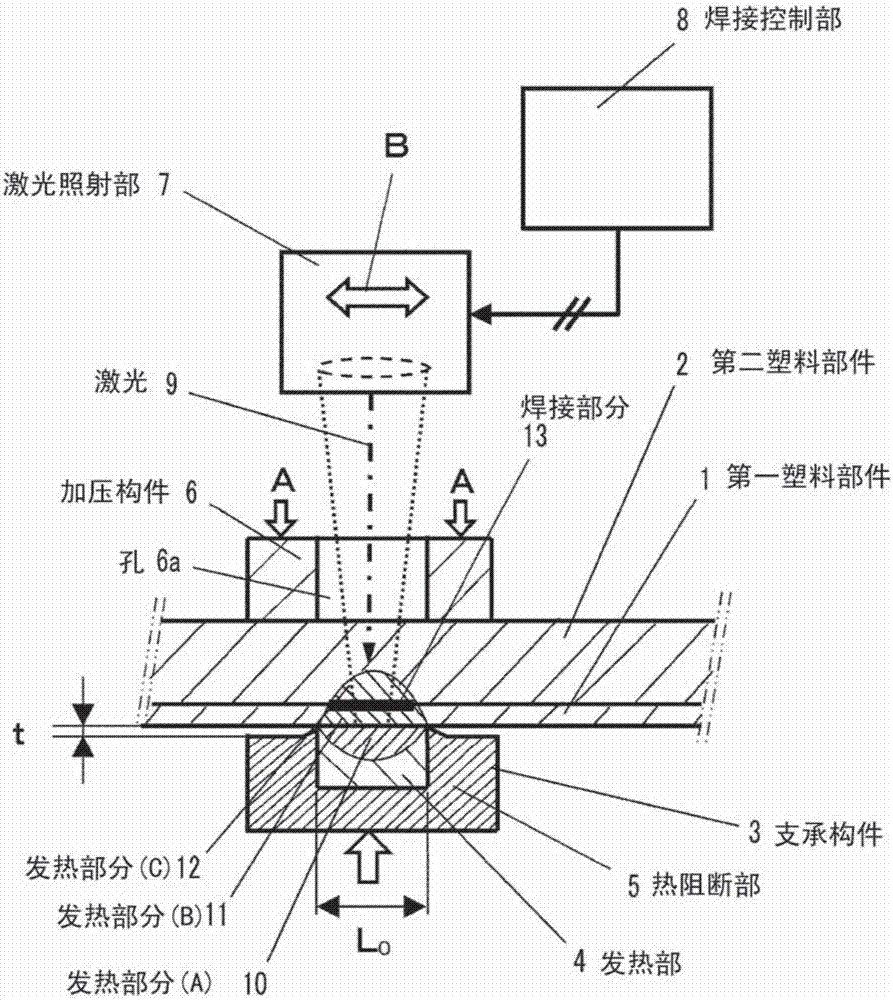

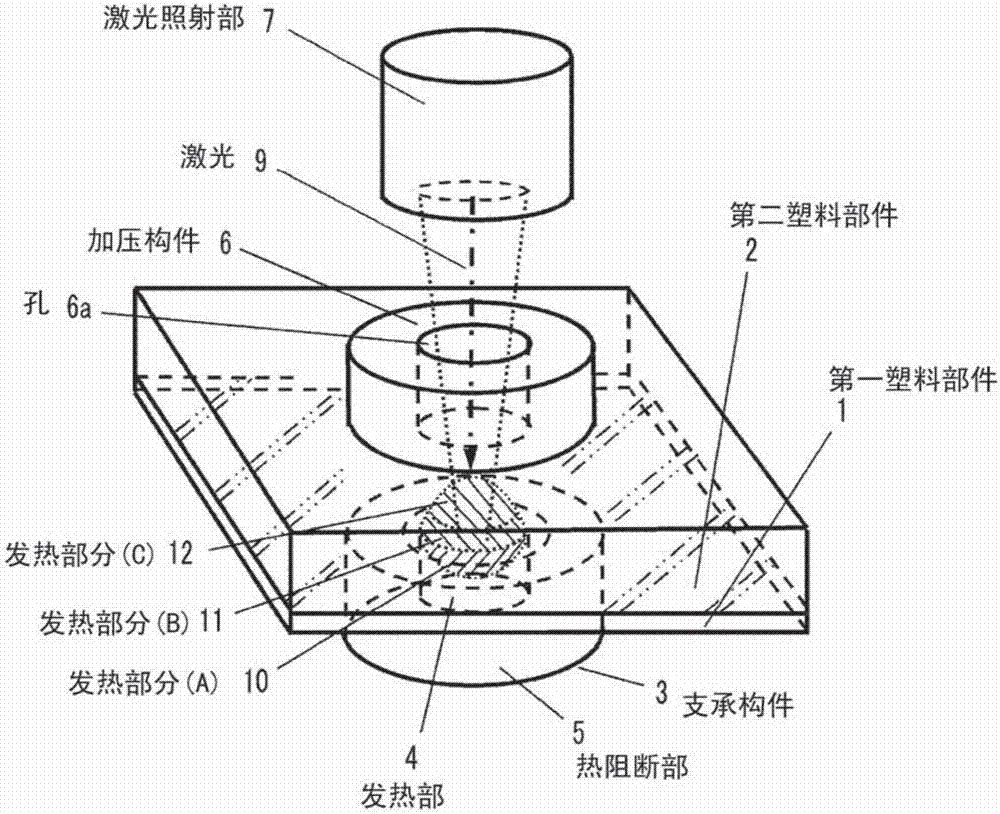

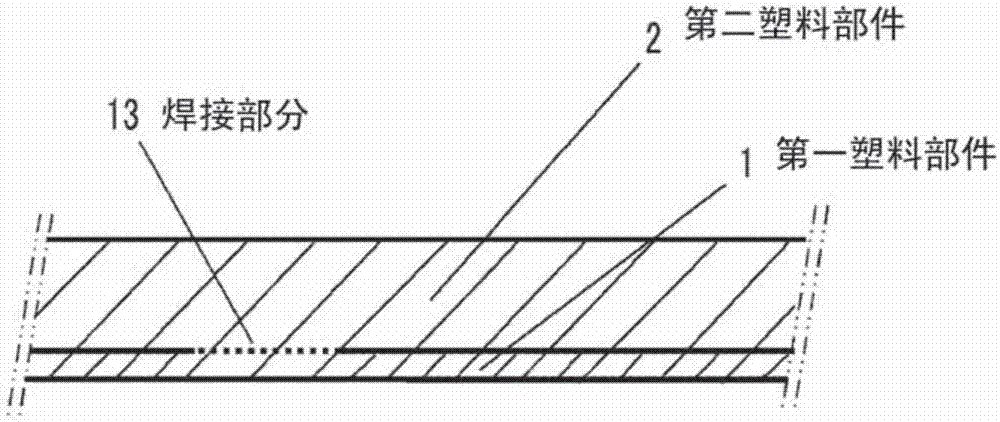

[0108] The principle of the laser welding method for the first and second plastic parts 1 and 2 will be described as a laser welding method for a plurality of plastic parts that transmits laser light according to the first embodiment of the present invention. figure 1 is a sectional view of the main part in the first embodiment, figure 2 is a stereogram.

[0109] figure 1 Among them, 1 and 2 are a plurality of plastic parts to be welded. Here, a method of welding the first plastic part 1 and the second plastic part 2 as a plurality of plastic parts will be described. For the case where the welding object is set to 3 plastic parts, use later Figure 6 to explain.

[0110] Both the first and second plastic parts 1 and 2 have low laser absorption rate and are made of a material that transmits laser light, such as thermoplastic resin such as polyamide resin. In addition, as a transparent resin material that transmits laser light, there are, for example, polyester, polyolef...

no. 2 approach

[0188] In the second embodiment, a description will be given of a case in which the welding range is cumulatively enlarged by gradually moving the position where the laser is irradiated with respect to the plate-shaped first and second plastic members 1h and 2h. Figure 18 It is a longitudinal sectional view showing the outline of a laser welding device according to a second embodiment of the present invention, Figure 19 is a cross-sectional view. In addition, the same code|symbol is attached|subjected to the same component as the said 1st Embodiment and a modification.

[0189] Figure 18 Among them, a supporting member 3b supporting the first and second plastic parts 1h, 2h is assembled to the central upper portion of the lower housing 16b. The support member 3 b is composed of a heat generating part 4 , a reflection part 14 , and a heat blocking part 5 , and the reflection part 14 and the heat blocking part 5 surround the heat generating part 4 . The upper surface of th...

no. 3 approach

[0207] Figure 23 It is an exploded perspective view of plastic parts welded by the laser welding method according to the third embodiment of the present invention. The first plastic member 1i is a thin circular sheet made of thermoplastic resin such as polyamide resin, and the second plastic member 2i is a hollow cylinder made of the same thermoplastic resin such as polyamide resin. Used when welding a thin, round thermoplastic resin sheet that is difficult to handle due to wrinkling or waviness, to a thin rigid frame of thermoplastic resin. In the laser welding device according to the third embodiment of the present invention, the surface near the outer periphery of the thin circular sheet made of thermoplastic resin as the first plastic member 1i is connected to the hollow circular sheet made of thermoplastic resin as the second plastic member 2i. The end face of the barrel is welded.

[0208] Figure 24 It is an exploded perspective view of a plastic component when weld...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap