Guangdong big-leaf yellow tea processing technology

A processing technology and large-leaf seed technology, which is applied in the field of Guangdong large-leaf yellow tea processing technology, can solve the problem that the yellow tea processing technology has not been well inherited, and it is difficult to process high-quality Guangdong large-leaf yellow tea and tea leaves. Uneven fermentation and other problems, to achieve the effect of eliminating grass gas, reducing the bitterness and astringency of tea, and tightening the shape of the rope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

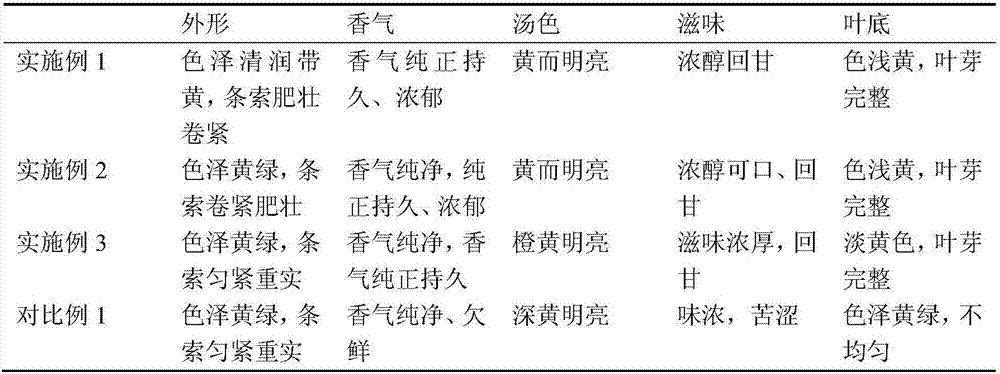

Examples

Embodiment 1

[0029] A processing technology of Guangdong big-leaf yellow tea, comprising the following steps:

[0030] S1. Picking and withering of fresh leaves: pick fresh tea leaves with one bud and two leaves from Guangdong big-leaf tea trees, and spread the picked fresh tea greens thinly on a clean bamboo curtain. The withering time is 5 hours. Do not turn the leaves during this period, and wither until the water content of the green tea is 70%;

[0031] S2. Fixing: first raise the temperature of the fixing machine to 180°C, then put the tea greens in S1 into the fixing machine, finish for 3 minutes, then increase the temperature of the fixing machine to 200°C, finish for 4 minutes, and then lower the temperature of the fixing machine To 180°C, continue to kill for 5 minutes;

[0032] S3. Cooling: take out the green tea after S2 is taken out, shake it quickly and spread it, the thickness of spreading is 3cm, the cooling time is 1h, during which it is turned once every 30min;

[0033]...

Embodiment 2

[0039] A processing technology of Guangdong big-leaf yellow tea, comprising the following steps:

[0040] S1. Picking and withering of fresh leaves: pick freshly stretched fresh tea leaves with one bud and three or four leaves from Guangdong big-leaf tea trees, and spread the picked fresh tea greens thinly on a clean bamboo curtain. The withering time is 8 hours , do not turn the leaves during the period, and wither until the water content of the dark green is 65%;

[0041] S2. Fixing: first raise the temperature of the fixing machine to 150°C, then put the green tea in S1 into the fixing machine, finish for 5 minutes, then increase the temperature of the fixing machine to 180°C, finish for 5 minutes, and then lower the temperature of the fixing machine To 150°C, continue to kill for 5 minutes;

[0042] S3. Cooling: Take out the green tea after S2 is taken out, shake it quickly and spread it to cool. The thickness of the spread is 3cm, and the cooling time is 1.5h. During thi...

Embodiment 3

[0049] A processing technology of Guangdong big-leaf yellow tea, comprising the following steps:

[0050] S1. Picking and withering of fresh leaves: pick freshly stretched fresh tea leaves with one bud and three or four leaves from Guangdong big-leaf tea trees, and spread the picked fresh tea greens thinly on a clean bamboo curtain. The withering time is 10 hours , do not turn the leaves during the period, wither until the water content of the dark green is 60%;

[0051]S2. Fixing: first raise the temperature of the fixing machine to 160°C, then put the green tea in S1 into the fixing machine, finish for 4 minutes, then increase the temperature of the fixing machine to 190°C, finish for 4 minutes, and then lower the temperature of the fixing machine To 160°C, continue to kill for 5 minutes;

[0052] S3. Cooling: take out the green tea after S2 is taken out, shake it quickly and spread it to cool. The thickness of the spread is 5cm, and the cooling time is 1h. During this peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com