Nanometer coating and printing material and preparation method thereof

A coating and nano technology, applied in the field of nano coating materials, can solve the problems of unfavorable industrialization and large-scale production, it is difficult to further improve performance, and the degree of performance improvement is limited, so as to shorten the production cycle, reduce the input of raw materials and production. Cost, breakthrough performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing a nano-coating material provided by an embodiment of the present invention, comprising:

[0017] The starting material and solvent are extracted.

[0018] Wherein, the weight ratio between the raw material and the solvent is 1:1-9. The raw materials include any one of paint raw materials and ink raw materials. The paint raw material includes at least one of a paint product raw material and a paint product. The ink raw material includes at least one of an ink product raw material and an ink product.

[0019] The extraction includes at least one of supercritical extraction, microwave extraction, ultrasonic extraction, ultra-high pressure extraction and nano-grinding extraction.

[0020] It should be noted that the coatings and inks in the embodiments of the present invention refer to coatings and inks in a broad sense. For example, the coatings in the embodiments of the present invention can be interior wall coatings, exterior wall coatings, etc....

Embodiment 1

[0069] Refining: Mix the raw materials with the solvent, and grind them into a slurry with a particle size of about 30 μm through a refiner.

[0070] Extraction: adopt supercritical extraction and microwave extraction in series. The extraction time of supercritical extraction is 10 min, and the extraction time of microwave extraction is 10 min.

[0071] Among them, the pressure of supercritical extraction is 80MPa, the power is 25Kw, the temperature is equal to 40°C, and the liquid flow rate is 2000L / h. The frequency of the microwave extraction is 915MHz, the power is 25Kw, the temperature is equal to 40°C, and the volume of the reaction tank is 1000L.

[0072] Emulsification: The extracted slurry is emulsified by a high-shear homogeneous emulsifier to obtain nano-coating materials.

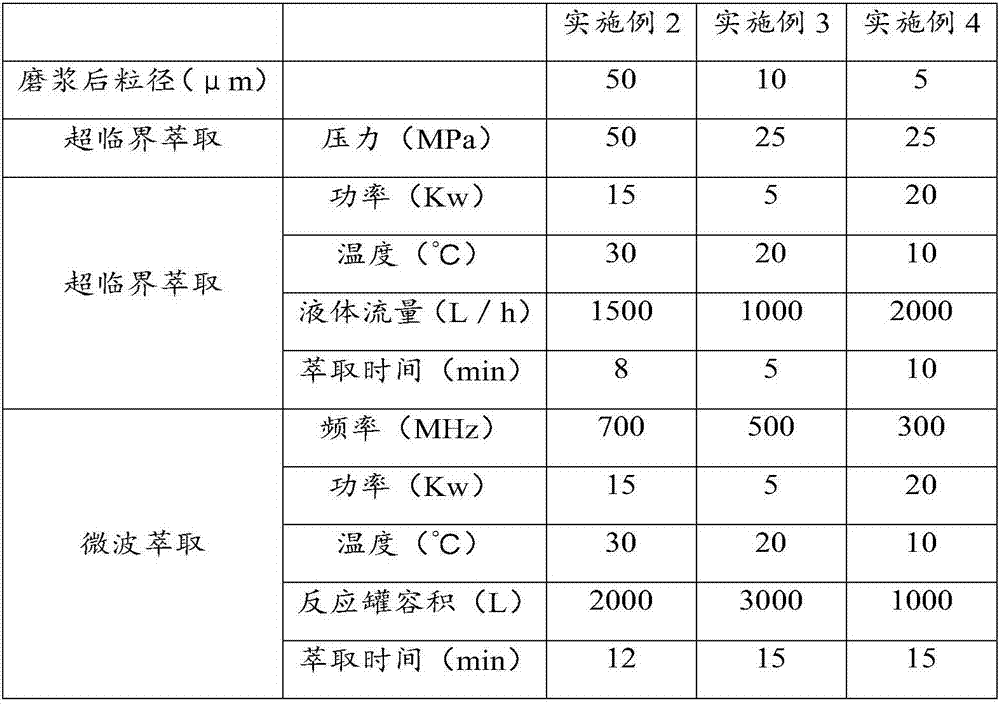

[0073] Examples 2 to 4 all adopt supercritical extraction and microwave extraction in series, and the relevant parameters are shown in Table 2, and other operations are the same as in Example 1...

Embodiment 5

[0077] Refining: Mix the raw materials with the solvent, and grind them into a slurry with a particle size of about 30 μm through a refiner.

[0078] Extraction: Ultrasonic extraction and ultra-high pressure extraction are used in series. The extraction time of ultrasonic extraction is 15 minutes, and the extraction time of ultra-high pressure extraction is 2 minutes.

[0079] Among them, the frequency of ultrasonic extraction is 50KHz, the power is 25Kw, the temperature is equal to 40°C, and the volume of the reaction tank is 1000L. The pressure of the ultra-high pressure extraction is 250MPa, the power is 25Kw, the temperature is equal to 40°C, the liquid flow rate is 1000L / h and the overpressure time is 2min.

[0080] Emulsification: The extracted slurry is emulsified by a high-shear homogeneous emulsifier to obtain nano-coating materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com