Ultrafine pulverization production line and technology thereof

A technology of ultrafine pulverization and ultrafine pulverizer, which is applied in lighting and heating equipment, grain processing, dryers, etc., can solve the problems of poor preparation effect of ultrafine powder, and achieve sufficient collision, reasonable structure, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

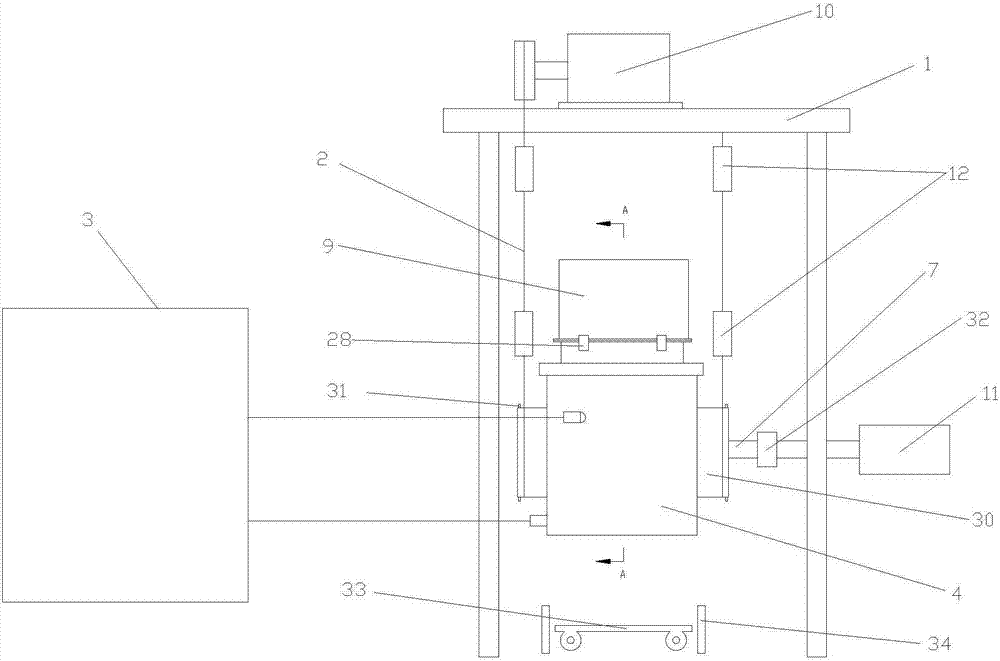

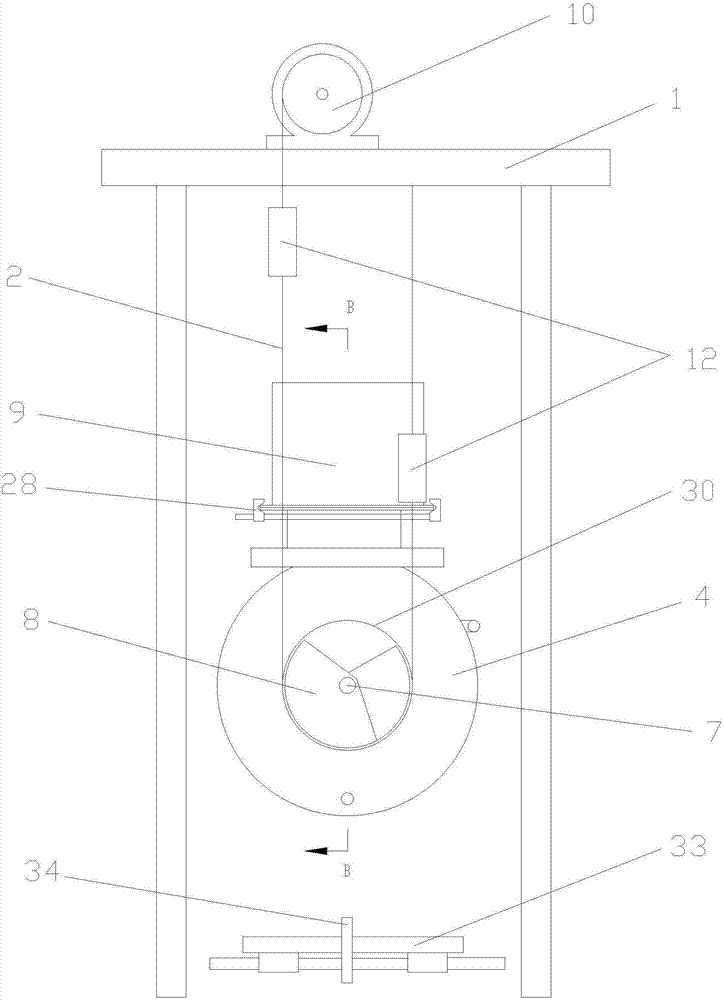

[0042] The present invention will be further described below in conjunction with the accompanying drawings:

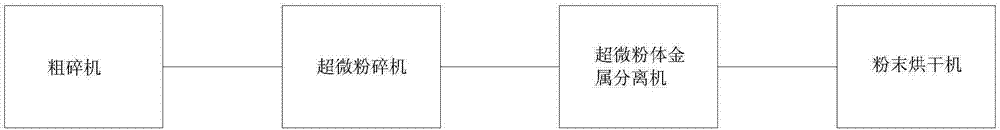

[0043] Referring to the accompanying drawings: this ultrafine pulverization line in this embodiment includes a coarse crusher, an ultrafine pulverizer, an ultrafine powder metal separator, a powder dryer, and the ultrafine pulverizer includes a fixed frame 1 , the top of the fixing frame is hung with a pulverizing device by winding the wire rope 2, the pulverizing device is connected with a cooling unit 3, a shock absorbing device 12 is connected in series on the steel wire rope 2, and the pulverizing device is provided with a cylindrical pulverizing main body 4, and the top of the pulverizing main body 4 has an opening formed The feeding port, the pulverizing body 4 is provided with a pulverizing cavity 5 that communicates with the feeding port, the pulverizing cavity 5 is filled with a number of left and right cylindrical grinding rods 56, and a cooling device is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com