Improved device for production of 3-amino-1-adamantanol

A technology of adamantanol and amino, which is applied in the field of improved equipment for the production of 3-amino-1-adamantanol, can solve the problems of high single impurity content of 3-amino-1-adamantanol, and achieve reduction of simple impurity content, The effect of saving water resources and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

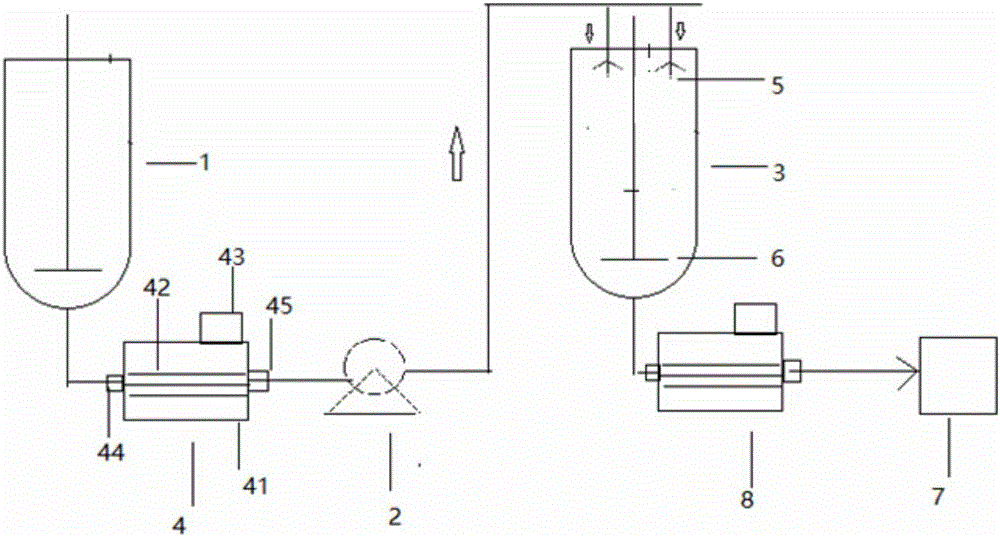

[0021] figure 1 Show an improved device for producing 3-amino-1-adamantanol, comprising a reaction liquid storage tank 1, a magnetic pump 2 and a reaction kettle 3 with stirring paddles connected in sequence by a catheter; the reaction liquid Ultrasonic devices are provided between the storage tank and the magnetic pump 2 and between the reaction kettle 3 and the centrifuge device 7 , namely the first ultrasonic device 4 and the second ultrasonic device 8 . The first ultrasonic device includes a box body 41, an ultrasonic vibrating plate 42 arranged inside the box body and an ultrasonic generating device 43 connected to the ultrasonic vibrating plate and arranged outside the box body; the inlet port of the box body 44 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com