Garbage can cleaning device capable of achieving air injection dehumidifying

A technology for cleaning devices and trash cans, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of slow drying speed and large water consumption, so as to reduce water consumption, improve drying efficiency, and improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

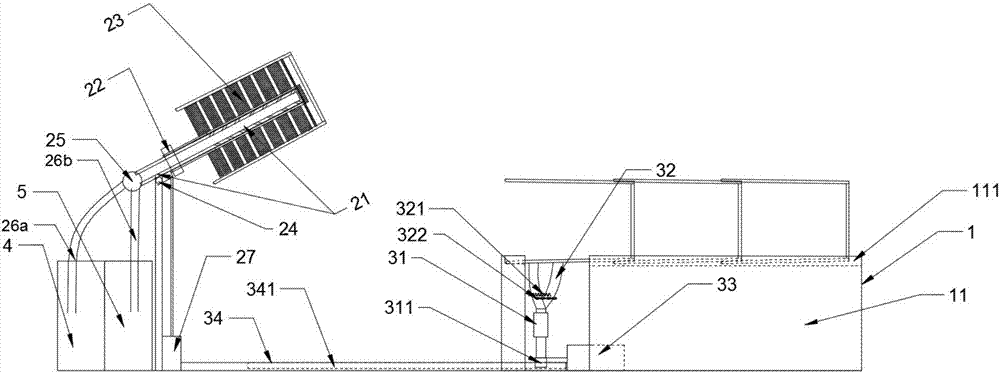

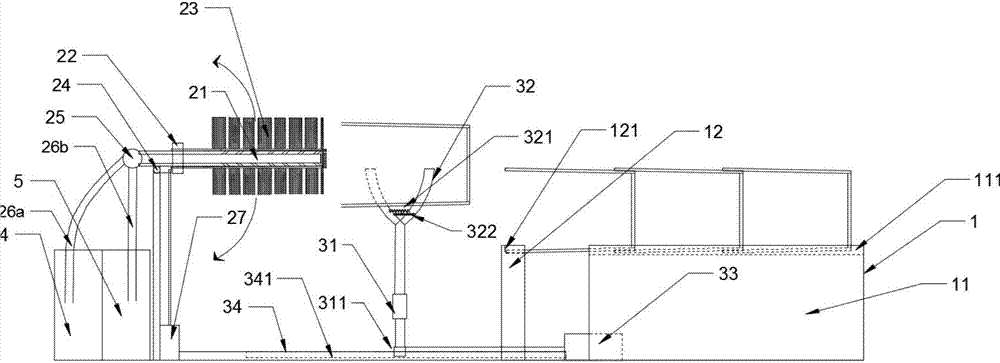

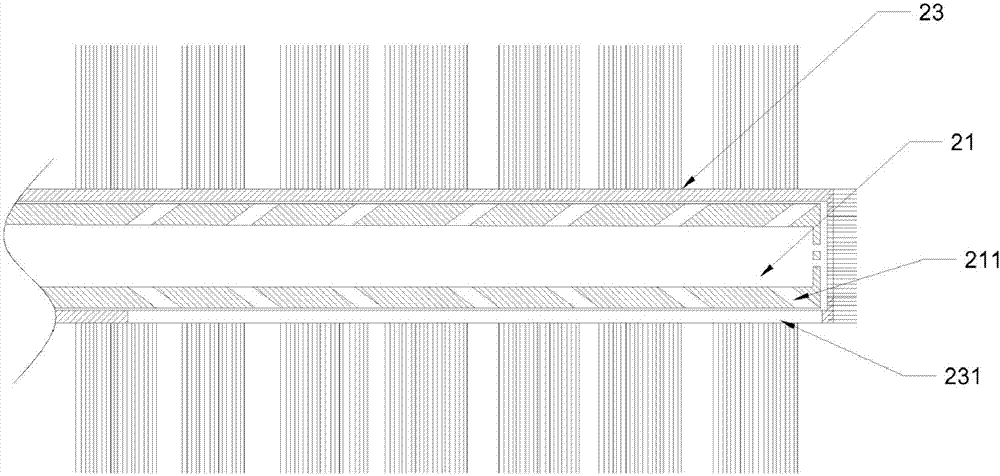

[0029] Such as figure 1 , figure 2 with image 3 As shown, the present embodiment provides a trash can cleaning device for air jet dehumidification, including a bucket setting platform 1, a cleaner 2 and a trash can transfer device 3, and the cleaner 2 includes a hinged bracket 24, a cavity rod with holes 21 and A brush 23 driven by a rotary joint, the brush 23 includes a hollow brush handle provided with a plurality of strip-shaped through holes 231 and bristles attached to the hollow brush handle, and one end of the holed cavity rod 21 is sealed and sleeved Inside the hollow brush handle of the brush 23, the other end of the hollow rod 21 with a hole passes through the swivel joint 22 and communicates with the water tank 4 and the air compressor 5 through the hose A26a and the hose B26b respectively. A control valve 25 is provided at the joint of the pipe B26b, and the hollow rod with holes 21 is provided with a plurality of rows of oblique holes 211 communicating with th...

Embodiment 2

[0036] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a trash can cleaning device for air jet dehumidification, including a bucket setting platform 1, a cleaner 2 and a trash can transfer device 3, and the cleaner 2 includes a hinged bracket 24, a cavity rod with holes 21 and A brush 23 driven by a rotary joint, the brush 23 includes a hollow brush handle provided with a plurality of strip-shaped through holes 231 and bristles attached to the hollow brush handle, and one end of the holed cavity rod 21 is sealed and sleeved Inside the hollow brush handle of the brush 23, the other end of the hollow rod 21 with a hole passes through the swivel joint 22 and communicates with the water tank 4 and the air compressor 5 through the hose A26a and the hose B26b respectively. A control valve 25 is provided at the joint of the pipe B26b, and the hollow rod with holes 21 is provided with a plurality of rows of oblique holes 211 communicating with the cavity. The h...

Embodiment 3

[0044] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a trash can cleaning device for air jet dehumidification, including a bucket setting platform 1, a cleaner 2 and a trash can transfer device 3, and the cleaner 2 includes a hinged bracket 24, a cavity rod with holes 21 and A brush 23 driven by a rotary joint, the brush 23 includes a hollow brush handle provided with a plurality of strip-shaped through holes 231 and bristles attached to the hollow brush handle, and one end of the holed cavity rod 21 is sealed and sleeved Inside the hollow brush handle of the brush 23, the other end of the hollow rod 21 with a hole passes through the swivel joint 22 and communicates with the water tank 4 and the air compressor 5 through the hose A26a and the hose B26b respectively. A control valve 25 is provided at the joint of the pipe B26b, and the hollow rod with holes 21 is provided with a plurality of rows of oblique holes 211 communicating with the cavity. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com