A kind of preparation technology of white ceramic handicraft

A ceramic handicraft and preparation technology, applied in the field of ceramics, can solve the problems of poor impact resistance of ceramic products, technical problems of white ceramics, etc., and achieve good coloring effect, excellent mechanical properties, and pure chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

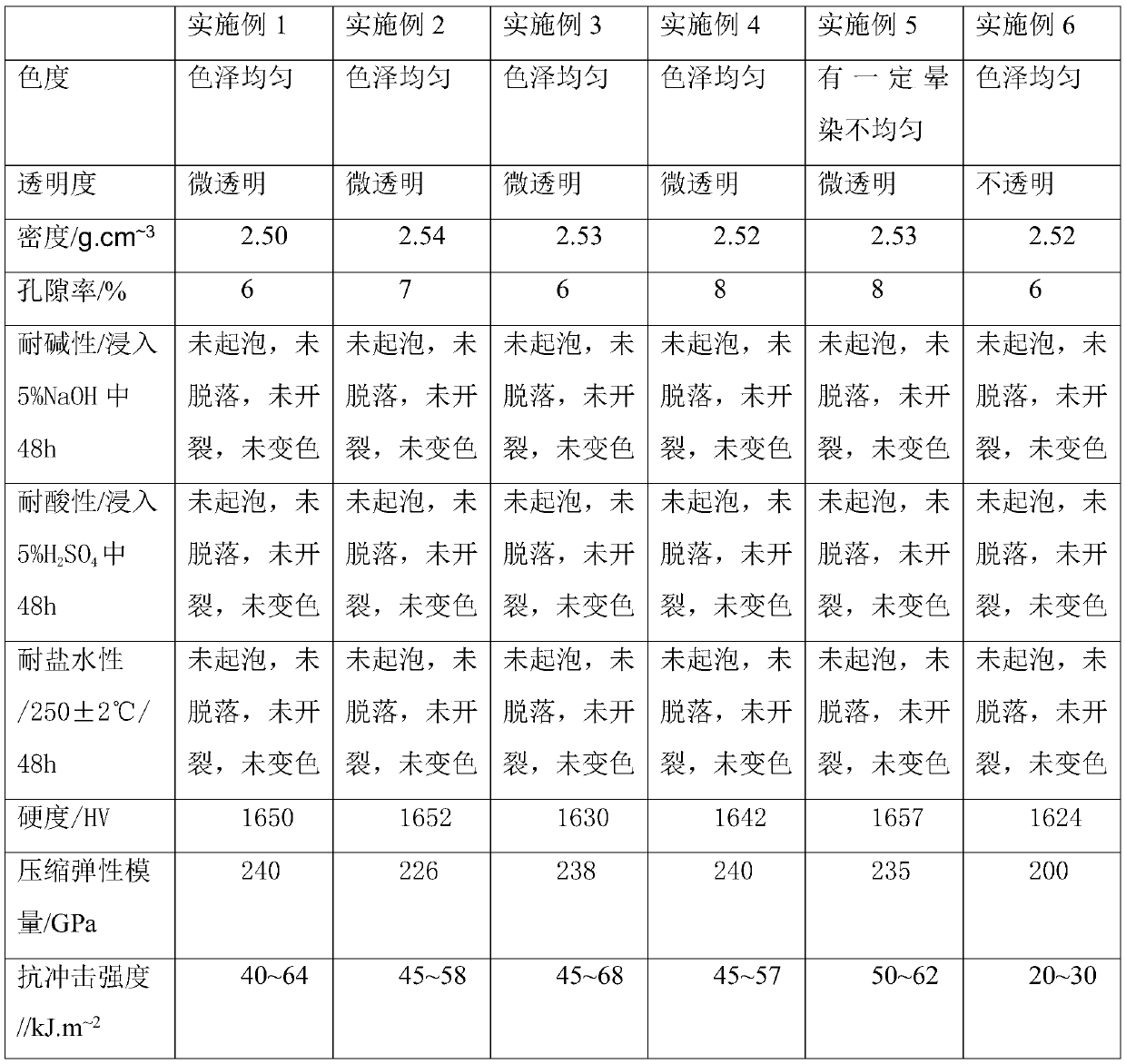

Examples

Embodiment 1

[0041] A preparation process of white ceramic handicraft includes the following steps:

[0042] S1 pottery clay process: remove impurities from kaolin and lithium porcelain stone, mix them to obtain pottery mud, divide the pottery clay into ceramic artworks, and stack them into columnar stacks;

[0043] S2 drawing process: Put the pile of mud in S1 into the big turntable, and pull the porcelain mud into a porcelain blank by rotating the turntable with hands and drawing tools;

[0044] S3 copper plate process: design and manufacture white film and cupronickel according to drawings;

[0045] S4 Discharging process: Add black discharging powder to the discharging puree, mix it evenly to obtain black discharging pigment, and discharging and coloring the printing area according to the design of the drawing. The pH of the black discharging pigment is 2;

[0046] S5 bisque firing process: the green body is bisquered at 1300℃ for 5 hours;

Embodiment 2

[0062] A preparation process of white ceramic handicraft includes the following steps:

[0063] S1 pottery clay process: remove impurities from kaolin and lithium porcelain stone, mix them to obtain pottery mud, divide the pottery clay into ceramic artworks, and stack them into columnar stacks;

[0064] S2 drawing process: Put the pile of mud in S1 into the big turntable, and pull the porcelain mud into a porcelain blank by rotating the turntable with hands and drawing tools;

[0065] S3 copper plate process: design and manufacture white film and cupronickel according to drawings;

[0066] S4 Discharging process: Add black discharging powder to the discharging puree, mix it evenly to obtain black discharging pigment, and discharging and coloring the printing area according to the design of the drawing. The pH of the black discharging pigment is 2.5;

[0067] S5 bisque firing process: the green body is bisquered at 1400℃ for 3h;

[0068] S6 glaze firing process: After glazing the body obt...

Embodiment 3

[0083] A preparation process of white ceramic handicraft includes the following steps:

[0084] S1 pottery clay process: remove impurities from kaolin and lithium porcelain stone, mix them to obtain pottery mud, divide the pottery clay into ceramic artworks, and stack them into columnar stacks;

[0085] S2 drawing process: Put the pile of mud in S1 into the big turntable, and pull the porcelain mud into a porcelain blank by rotating the turntable with hands and drawing tools;

[0086] S3 copper plate process: design and manufacture white film and cupronickel according to drawings;

[0087] S4 Discharging process: add black discharging powder to the discharging puree, mix it evenly to obtain black discharging pigment, and discharging and coloring the printing area according to the design of the drawing, and the pH of the black discharging pigment is 3;

[0088] S5 biscuit firing process: the green body is biscuited at 1350℃ for 4h;

[0089] S6 glaze firing process: After glazing the body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com