Automatic distribution mechanism for stock bins

A material distributing mechanism and silo technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as affecting the efficiency of feeding automation, vibration of materials in the tray, and large vibration of the tray, etc. Achieve the effect of simple structure, good rotation consistency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Referring to the accompanying drawings, a description will be given in detail of a silo automatic distributing mechanism of the present invention.

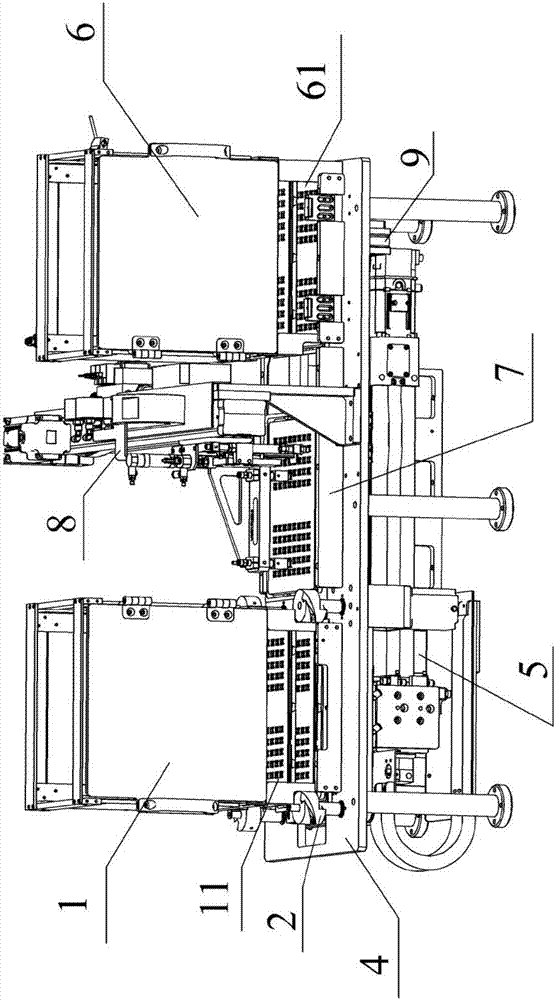

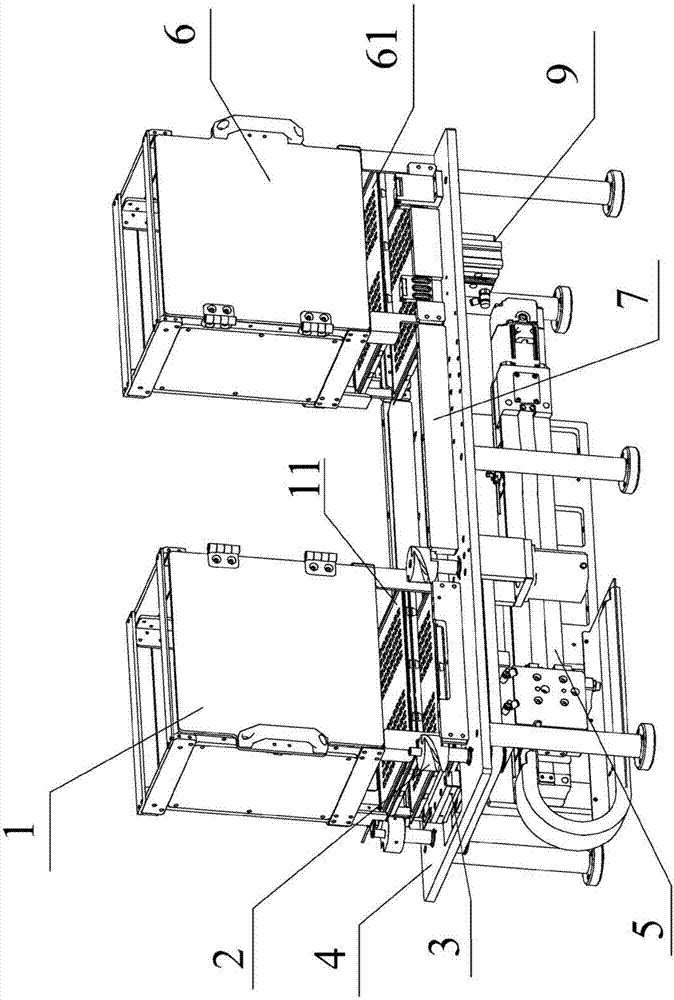

[0018] like figure 1 , figure 2 As shown, a bin automatic distributing mechanism includes a full-pan bin 1 for stacking insert trays 11, a bottom part of the full-pan bin 1 for making the insert tray 11 Separated from the full tray silo 1 separating device 2 and the tray positioner 3 for positioning the detached insert tray 11; also includes a unit located at the bottom of the base 4 supporting the full tray 1 Axis robot 5 and an empty tray bin 6 for storing empty trays 61 located on the other side of the base 4 top; The track 7 for transporting the insert tray 11 and the empty tray 61 and the handling device 8 located on one side of the track 7 for insert picking the insert tray 11; The lower part of the empty tray storage bin 6 is installed on the lifting cylinder 9 on the base 4 .

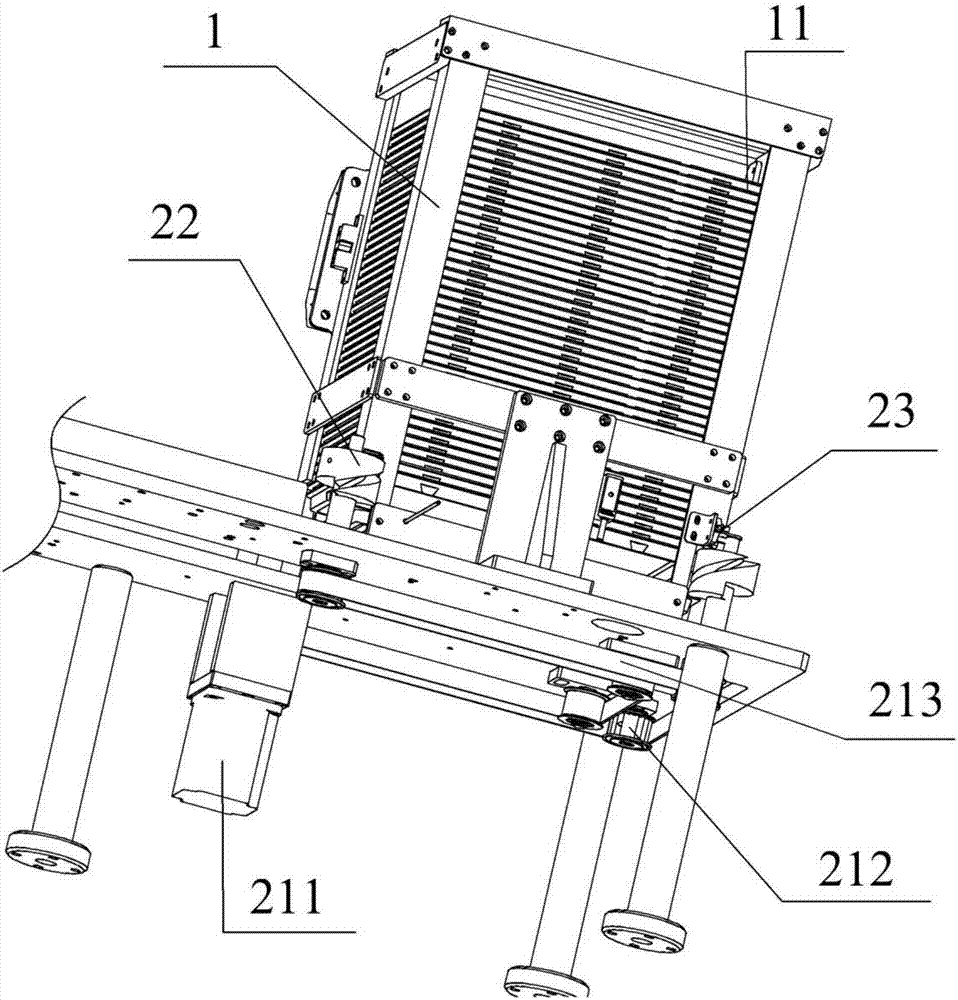

[0019] like image 3 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com