Preparation method, device and system for quartz ingots

A quartz ingot and quartz technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of low material yield, high material yield, and uneven size of quartz ingots, so as to improve the material yield and increase the loss of raw materials , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

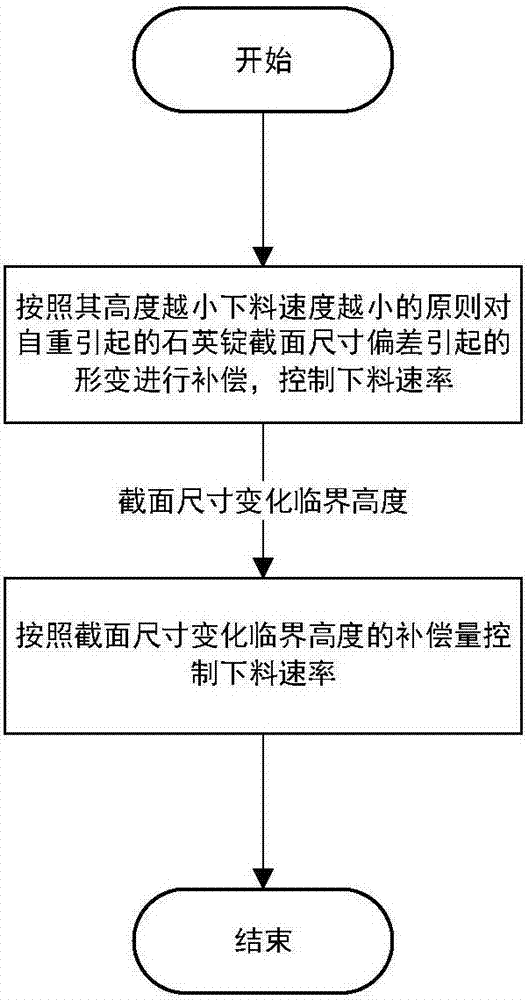

[0041] The preparation method of the quartz ingot provided by the present invention adopts the gas refining method to deposit the quartz ingot and controls the feeding rate according to the following steps:

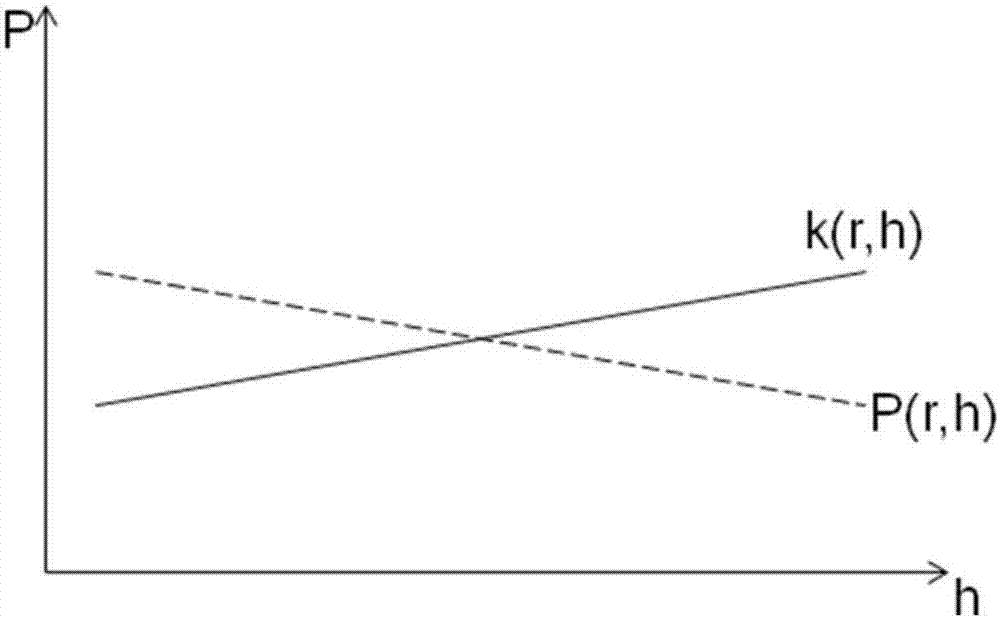

[0042] When the height of the deposited quartz ingot is lower than the critical height of the cross-sectional size change, according to the principle that the smaller the height, the lower the feeding speed, the deformation caused by the deviation of the cross-sectional size of the quartz ingot caused by the self-weight is compensated, and the feeding rate is controlled;

[0043] When the height of the deposited quartz ingot is higher than the critical height of the cross-sectional dimension change, the feeding rate is controlled according to the compensation amount of the critical height of the cross-sectional dimension change.

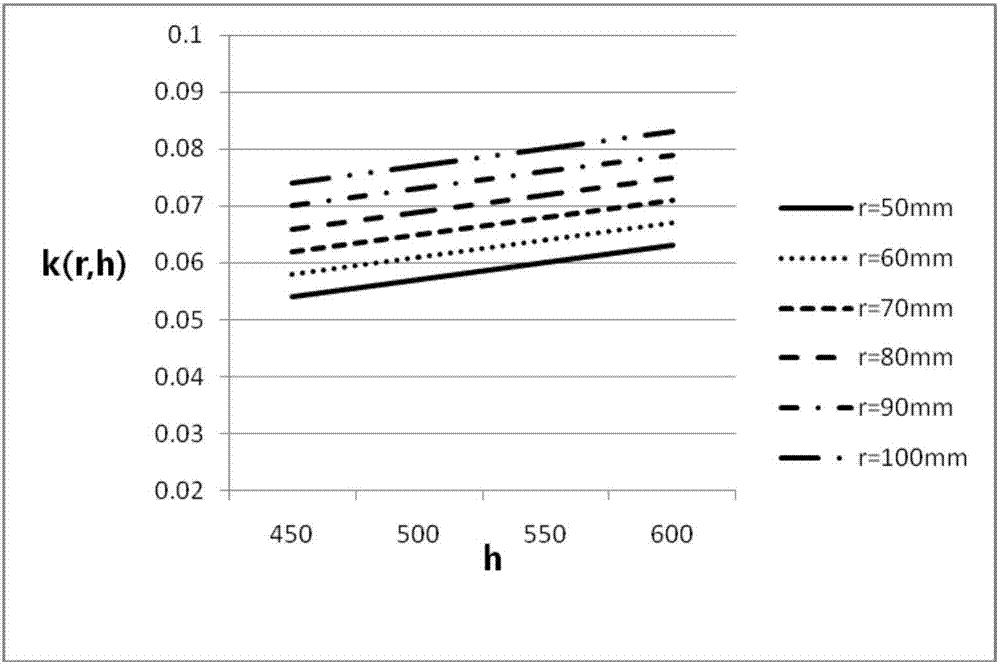

[0044] V 1 =[1+k(r,h)]V 2 r 2 ρ

[0045] where: V 1 is the feeding rate, that is, the amount of raw materials put in per unit time; V 2 r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com