Detergent composition and method for improving oil stain emulsifying and dispersing capacity of detergent

An emulsifying and dispersing, detergent technology, applied in detergent compositions, surface active detergent compositions, detergent compounding agents, etc., can solve problems such as detergent damage to the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] Embodiment 1 and comparative examples 1~4

[0157] Liquid detergent compositions A, X, Y, Z and W were formulated according to the composition of Table 1 below.

[0158] Each component and performance of liquid detergent composition A, X, Y, Z and W in Table 1 embodiment 1, comparative examples 1~4

[0159] Example

Example 1

Comparative example 1

Comparative example 2

Comparative example 3

Comparative example 4

combination

A

X

Y

Z

W

components

content(%)

content(%)

content(%)

content(%)

content(%)

NaOH

2.0

2.0

3.0

Monoethanolamine

2.0

2.0

12

12

12

12

16

AES

3

3

3

3

12

AEO9

5

5

5

EH-6

5

5

LAB

1.5

1.5

1.5

1.5

0.5

AOS

2.5

2.5

2.5

2.5

2.5

CMIT / MIT

0.005

0.005

0.005

0.005

0.005

...

Embodiment 1~6

[0163] Liquid detergent compositions A to F were formulated according to the composition in Table 2 below.

[0164] Each component and performance of the liquid detergent composition A~F of table 2 embodiment 1~6

[0165]

[0166]

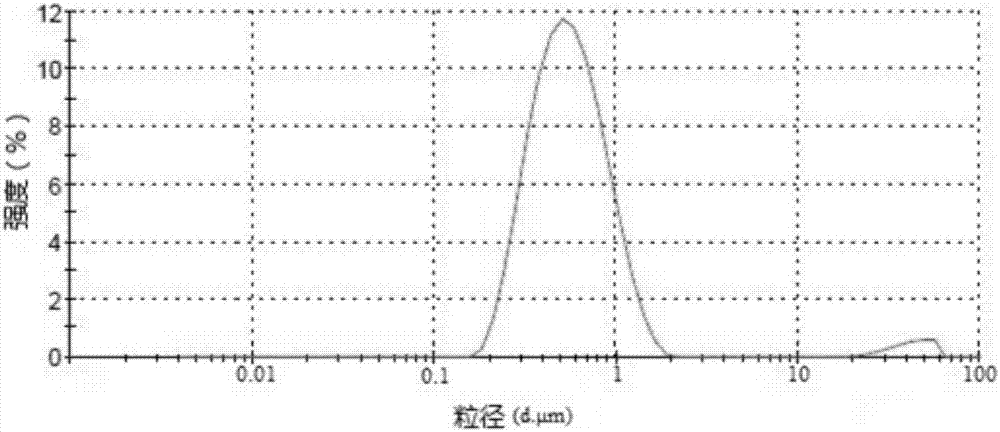

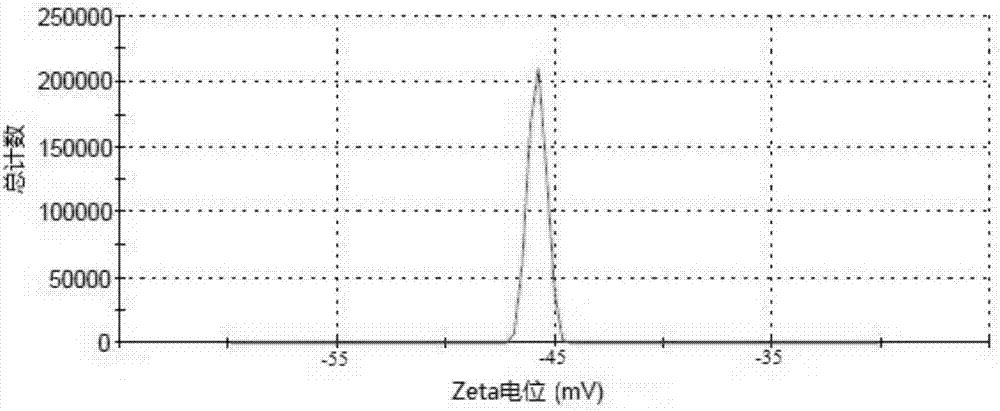

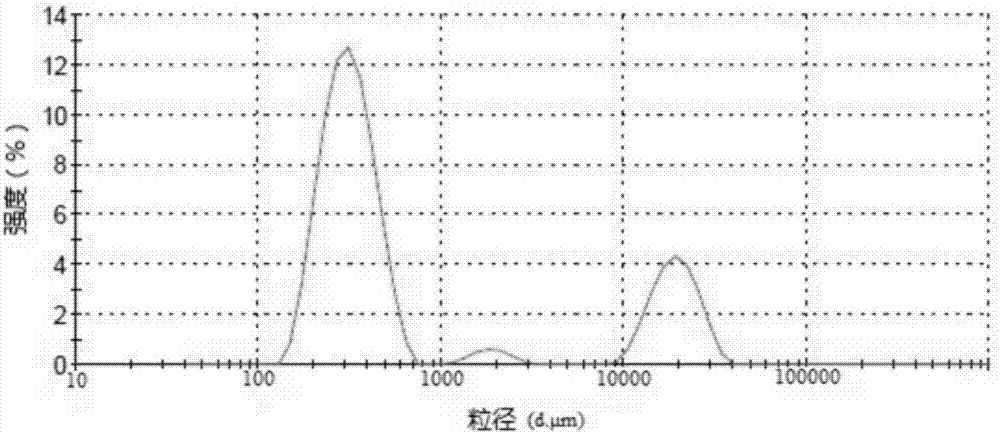

[0167]The test results of liquid detergent compositions A to F prepared in Examples 1 to 6 are shown in Table 3. In the three main tests, compositions A to F have little difference, and composition D has a slight advantage. It can be seen from the test of emulsion particle size and Zeta potential that although different types of alkylamines have little effect on the result value in terms of emulsion particle size, long-chain alkylamines have a greater advantage than ethanolamine in the Zeta potential test , which is mainly due to the fact that its alkyl chain can be combined with an anionic hydrophobic structure. However, considering the solubility of the alkylamine itself, an excessively long alkyl chain may cause problems in the stability ...

Embodiment 4 and Embodiment 7~11

[0169] Liquid detergent compositions D and G-K were formulated according to the composition in Table 3 below.

[0170] Each component and performance of liquid detergent composition D and G~K in the embodiment 4 of table 3 and embodiment 7~11

[0171]

[0172]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com